High-security metallic lithium cathode and preparation method thereof

A high-safety, metal lithium technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as failure to meet practical standards, deterioration of electrochemical performance, capacity loss, etc., to improve battery rate charge and discharge capacity and use Longevity, prevention of lithium dendrites, and performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

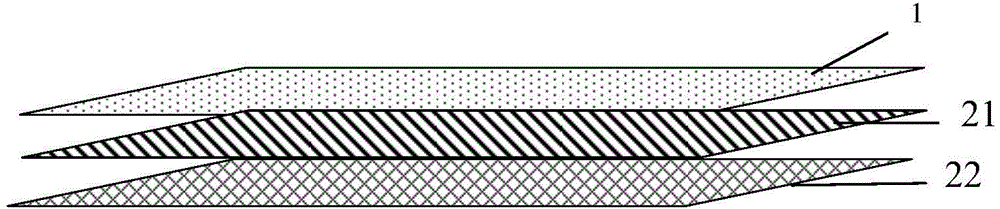

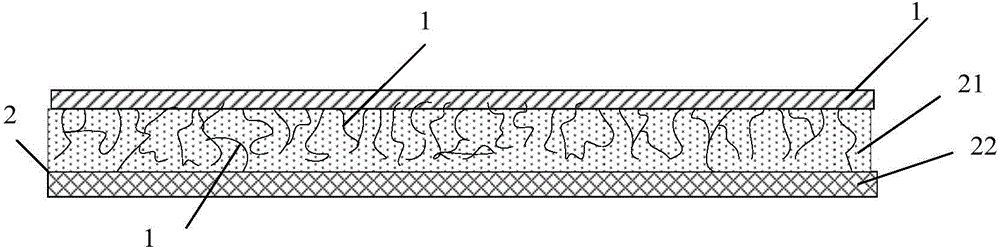

[0039] Such as figure 1 with figure 2 As shown, a high-safety metal lithium negative electrode includes a lithium powder porous electrode 2 and a silicon-based protective layer 1, and also includes a negative electrode tab; the lithium powder porous electrode 2 includes a lithium powder material layer 21 and a copper foil 22, The lithium powder porous electrode 2 is formed by mixing the lithium powder and the binder PVDF in a tetrahydrofuran solvent, coating it on the copper foil 22, and forming it through sheeting; the silicon-based protective layer 1 is formed by vacuum coating The silicon-based material is vapor-deposited on the lithium powder material layer 21, and the thickness of the silicon-based protective layer 1 is 0.02-0.2 μm.

[0040] Such as figure 2 As shown, since the lithium powder porous electrode 2 is a powder porous electrode, when the silicon-based protective layer 1 adopts the vacuum coating method to vapor-deposit silicon-based materials on the lithiu...

Embodiment 2

[0045] On the basis of Example 1, the structure of the high-safety metal lithium negative electrode in this example is the same as that in Example 1, only the preparation method is different. In this example, the following steps are used to prepare:

[0046] Stir the mixture of molten lithium metal and 250°C hot silicone oil at 30,000 rpm at high speed to form a dispersion system, cool to room temperature to obtain lithium metal powder, wash three times with cyclohexane and dry at room temperature to obtain lithium metal powder with a particle size of 18-30 μm; The mass ratio of metal lithium powder and binder PVDF is 80:20. Weigh the prepared metal lithium powder and binder PVDF respectively, and inject tetrahydrofuran 2.0 times the mass of metal lithium powder and binder PVDF solid powder into vacuum Stirring machine, stirring for 4h to mix the slurry, coating on the pre-treated copper foil, drying, tableting to prepare the lithium powder porous electrode 2; put the silicon-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com