Tinned copper belt production line for solar cell module

A technology for solar cells and tinned copper strips, applied to electrical components, electrical solid devices, circuits, etc., can solve problems affecting the quality of tinned copper strips, hidden dangers of copper strip quality, and low production efficiency, achieving simple structure and ensuring Production efficiency and the effect of ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

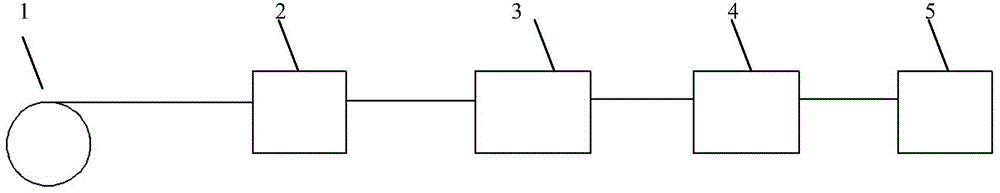

[0033] like figure 1 As shown, the present invention provides a solar cell module tinned copper strip production line, including a feeding mechanism 1, a bright annealing furnace 2, a calender 3, a tin furnace 4 and a winding machine 5, which are sequentially arranged along the feeding direction.

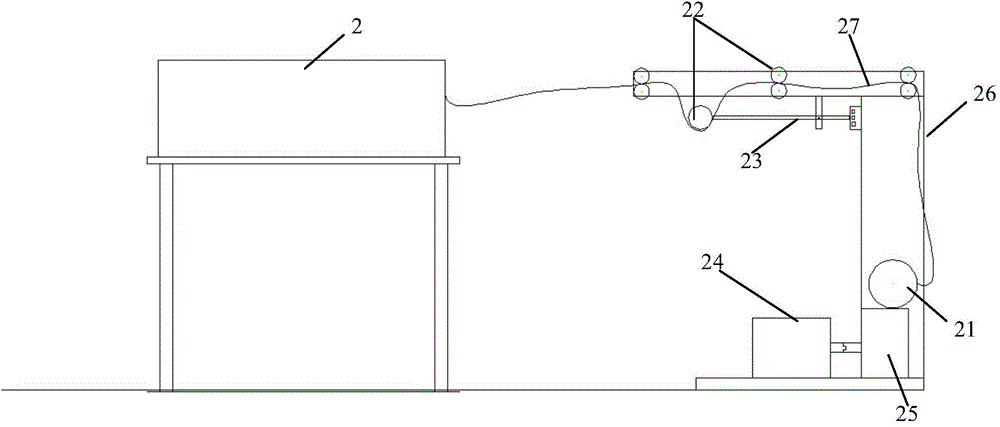

[0034] combine figure 1 and refer to figure 2 As shown, the feeding mechanism 1 in the tinned copper strip production line provided by the present invention is an automatic feeding mechanism, including a copper wire reel 21, a feeding roller 22, a position sensor 23, a frequency conversion mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com