A kind of construction method of cage type space grid structure steel bar connector with cone

一种钢筋连接器、空间网格的技术,应用在结构要素、建筑构件、制造工具等方向,能够解决强度降低、连接强度降低、施工难度增大等问题,达到抗弯能力提高、自身重量减轻、节约建筑成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

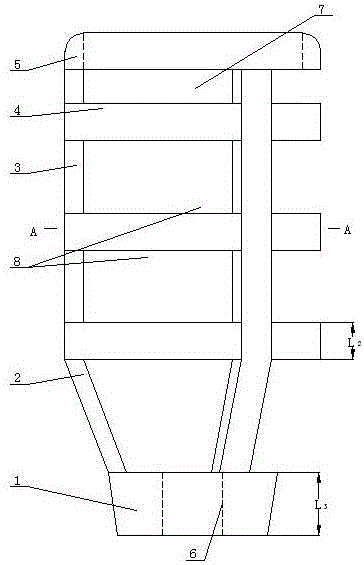

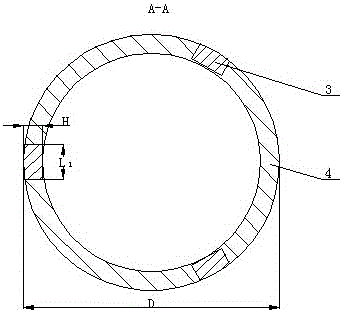

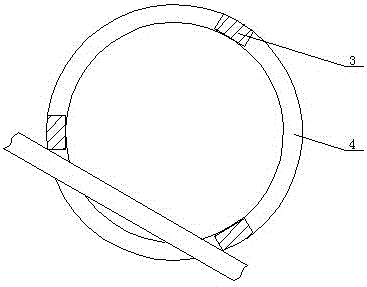

[0013] A steel bar connector with a cage space grid structure with a cone according to the present invention includes a cone 1, a through hole 6 is opened on the cone 1, threads are arranged on the hole wall of the through hole 6, and the diameter of the cone 1 is large. The circumference of the diameter end is connected to one end of at least two oblique support ribs 2, and the other end of each oblique support rib 2 is respectively connected to one end of the respective longitudinal support rib 3, and multiple longitudinal support ribs 3 are evenly distributed within 360° , the diameter of the outer wall of a plurality of longitudinal support ribs 3 is the same as the outer diameter of the large diameter end of the cone 1, and the other end of each longitudinal support rib 3 is connected with the support ring 5, the cone 1, the oblique support rib 2, and the support ring 5 It is connected with a plurality of longitudinal support ribs 3 to form a cylindrical frame, and at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com