double arch gate

A gate and gate body technology, which is applied in the field of double-sided arched gates, can solve problems such as the increase in reinforced concrete engineering volume, the gate cannot be opened and closed directly, and the self-heaviness of the gate, so as to achieve small reinforced concrete engineering volume, increase rigidity, The effect of high gate rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

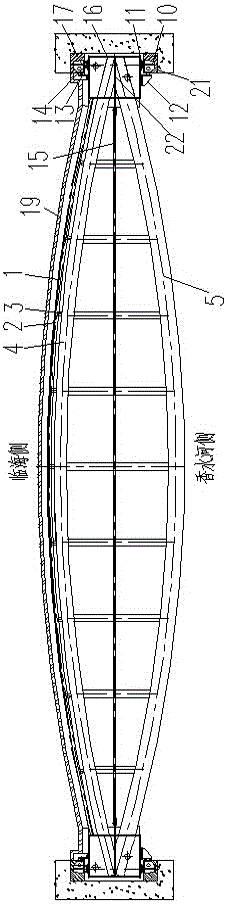

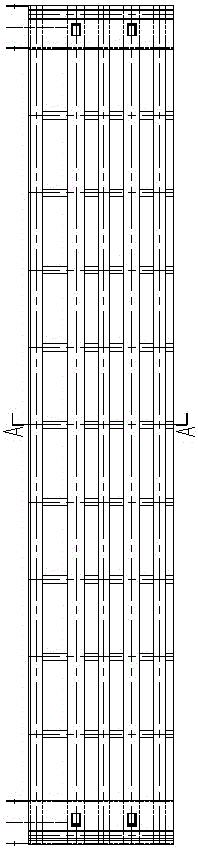

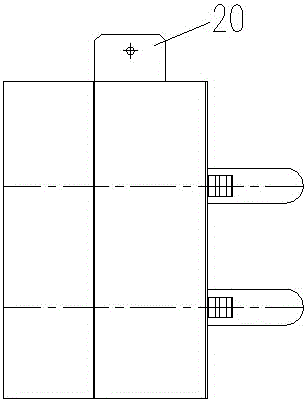

[0027] Such as Figure 1-Figure 5 As shown, it is a double-arch gate, one side of the gate faces the sea, and the other side is the Perfume River. The gate includes a door body and embedded parts. The truss girder system, prestressed tie rods 15, and box-shaped end columns 16 arranged on the left and right sides of the gate. The truss beam system includes a plurality of upper chord arch tubes 4 arranged at intervals from top to bottom, and a plurality of lower chord arch tubes 5 arranged at intervals from top to bottom in sequence, and the two ends of each upper chord arch tube 4 and lower chord arch tube 5 are respectively Connected with the box-shaped end columns 16 on the left and right sides of the gate, the arching direction of the upper chord arch tube 4 and the lower chord arch tube 5 are opposite, forming an olive-shaped double arch structure in the plan view, and the upper chord arch tube 4 passes through multiple The two vertical connecting pipes 25 are connected, t...

Embodiment 2

[0033] Such as Figure 6-Figure 8As shown, this embodiment is basically the same as Embodiment 1, the difference is that the upper chord arch tube 4 in this embodiment includes an arched upper beam 23 arranged on the upper part and a plurality of arched beams 23 arranged on the lower part in turn. Bending into arched steel pipes, the panel 1 is directly welded together with the last beam 23 and one side of the steel pipes, and the last beam 23 and each steel pipe are connected together by longitudinal beam webs 24. In this embodiment, the upper beam 23 constituting the upper chord arch tube 4 is made of I-beam, and the steel pipe is made of a square tube or a rectangular tube or a box-shaped structure.

[0034] Other parts in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com