Thermoplastic rigid polyurethane foam for automotive interior and preparation method thereof

A technology of rigid polyurethane and automotive interiors, applied in the field of chemical materials, can solve the problems of atmospheric destruction, high-tech threshold of ceiling system, foam heartburn, etc., and achieve the effects of low cost, excellent extension effect, and high opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of rapeseed oil derivatives:

[0034] Take 20Kg of the small molecule polyol mixture (the molar ratio of triethanolamine, glycerol and trimethylolpropane is 3:5:2), and the molar ratio of them to rapeseed oil is 2:1, pour it into the reaction kettle, and add 0.16Kg After replacing the PbO catalyst with nitrogen, start stirring, and at the same time raise the temperature to 210°C for 2.5 hours to obtain a rapeseed oil derivative (i.e. alcoholysis product); then add PU3318 antioxidant 0.075Kg and ChicF96 antioxidant to the reaction kettle 0.025Kg, stirred at 85°C for 1 hour, released after stirring fully.

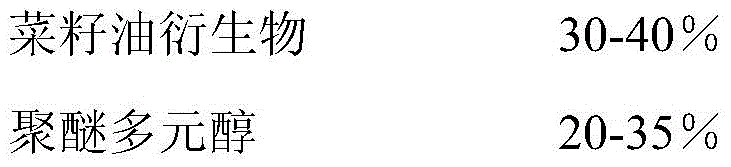

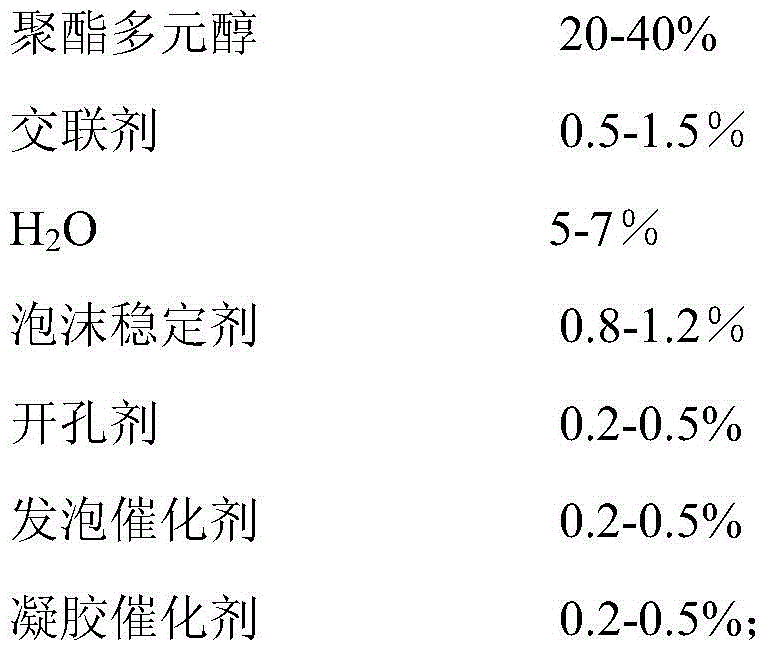

[0035] (2) Preparation of component A:

[0036]

[0037]

[0038] Put the above prepared rapeseed oil derivatives, polyether polyols, and polyester polyols into the reactor and stir for 10 minutes, then add water, foaming catalyst, gelling catalyst, foam stabilizer, crosslinking agent, and cell opener , stirred and reacted at room temperature, s...

Embodiment 2

[0042] (1) Preparation of rapeseed oil derivatives:

[0043] Weigh 20Kg of the small molecule polyol mixture (the molar ratio of triethanolamine, glycerin and trimethylolpropane is 2:3:5), the molar ratio of them to rapeseed oil is 1.9:1, pour it into the reaction kettle, add 0.16 Kg of PbO catalyst, after nitrogen replacement, start stirring, and simultaneously heat up to 250 ° C for 1.5 hours to obtain rapeseed oil derivatives (i.e. alcoholysis products); then add PU3318 antioxidant 0.025Kg and ChicF96 anti-oxidant to the reaction kettle Oxygen agent 0.075Kg, stirred at 80°C for 1.5h, released after fully stirred.

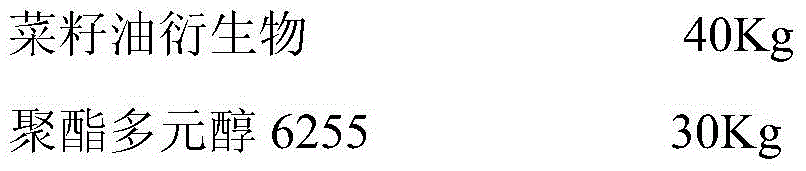

[0044] (2) Preparation of component A:

[0045]

[0046]

[0047] Put the above prepared rapeseed oil derivatives, polyether polyols, and polyester polyols into the reactor and stir for 15 minutes, then add water, foaming catalyst, gelling catalyst, foam stabilizer, crosslinking agent, and cell opening agent , stirred and reacted at room temperature, stir...

Embodiment 3

[0051] (1) Preparation of rapeseed oil derivatives:

[0052]Weigh 20Kg of the small molecule polyol mixture (triethanolamine, glycerol and trimethylolpropane molar ratio is 2:5:3), and their molar ratio to rapeseed oil is 2:1, pour it into the reactor, add 0.16 Kg of PbO catalyst, after nitrogen replacement, start stirring, and at the same time raise the temperature to 230 ° C for 2 hours to obtain rapeseed oil derivatives (i.e. alcoholysis products); the second is to add PU3318 antioxidant 0.05KG and ChicF96 in the reaction kettle Antioxidant 0.05Kg, stir at around 75°C for 0.5h, release after stirring fully.

[0053] (2) Preparation of component A:

[0054]

[0055] Put the above prepared rapeseed oil derivatives, polyether polyols, and polyester polyols into the reactor and stir for 12 minutes, then add water, foaming catalyst, gel catalyst, foam stabilizer, crosslinking agent, and cell opening agent , stirred and reacted at room temperature, stirred for 2.5 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com