Carbon nanometer material radiating module

A carbon nanomaterial, heat dissipation module technology, applied in the fields of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of high price, poor thermal conductivity, large quality of copper materials, etc. Production cost, improved heat dissipation efficiency, low expansion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

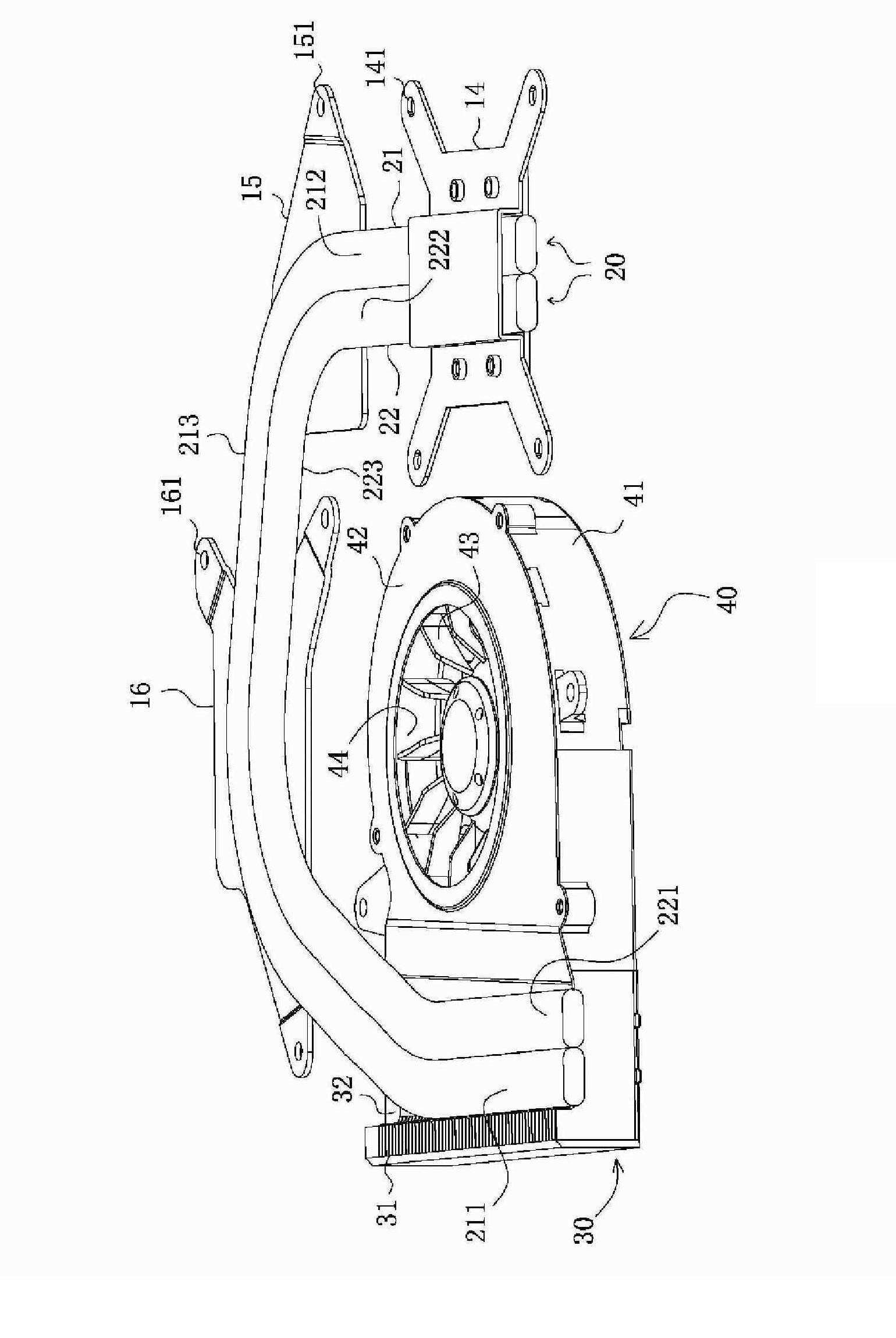

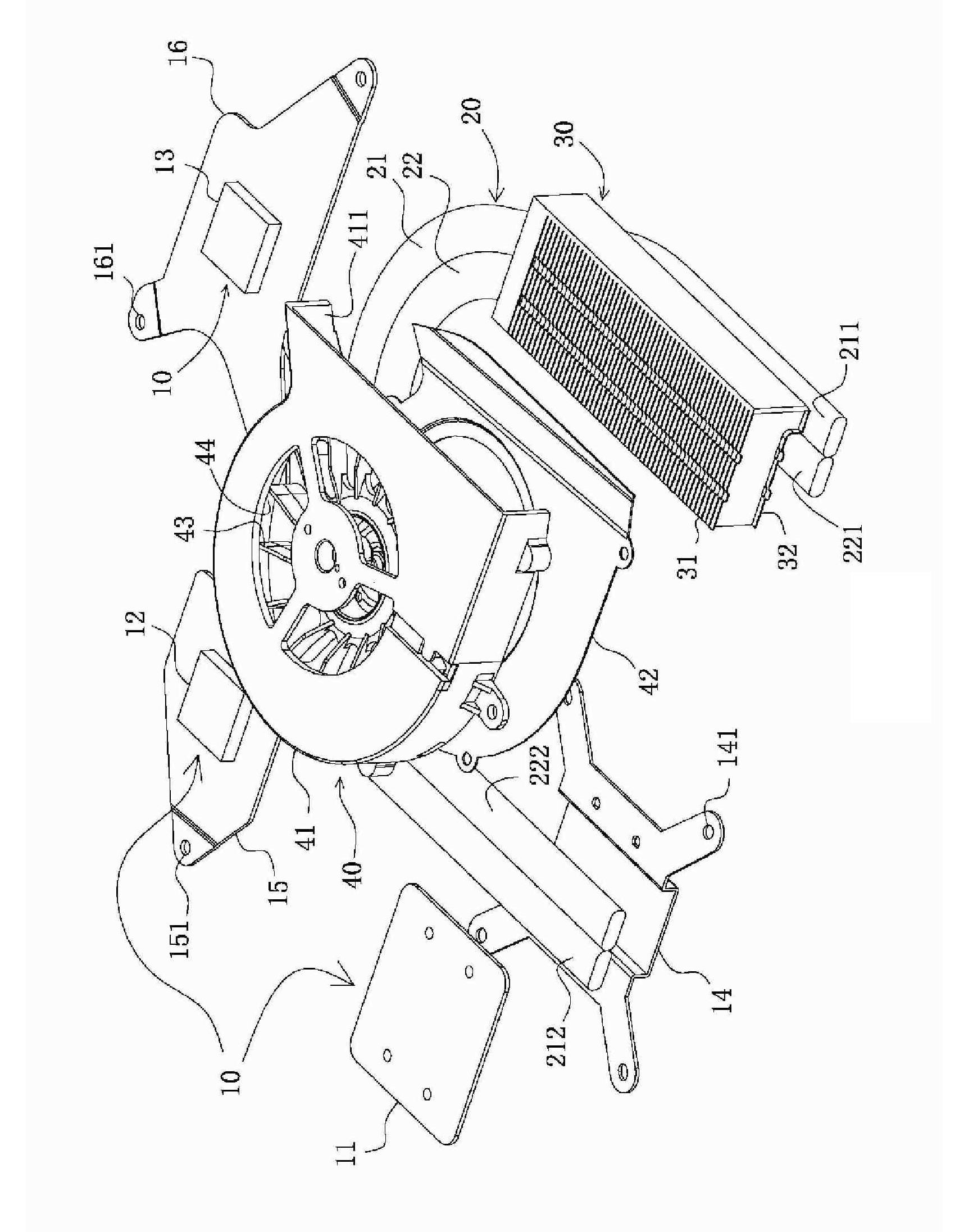

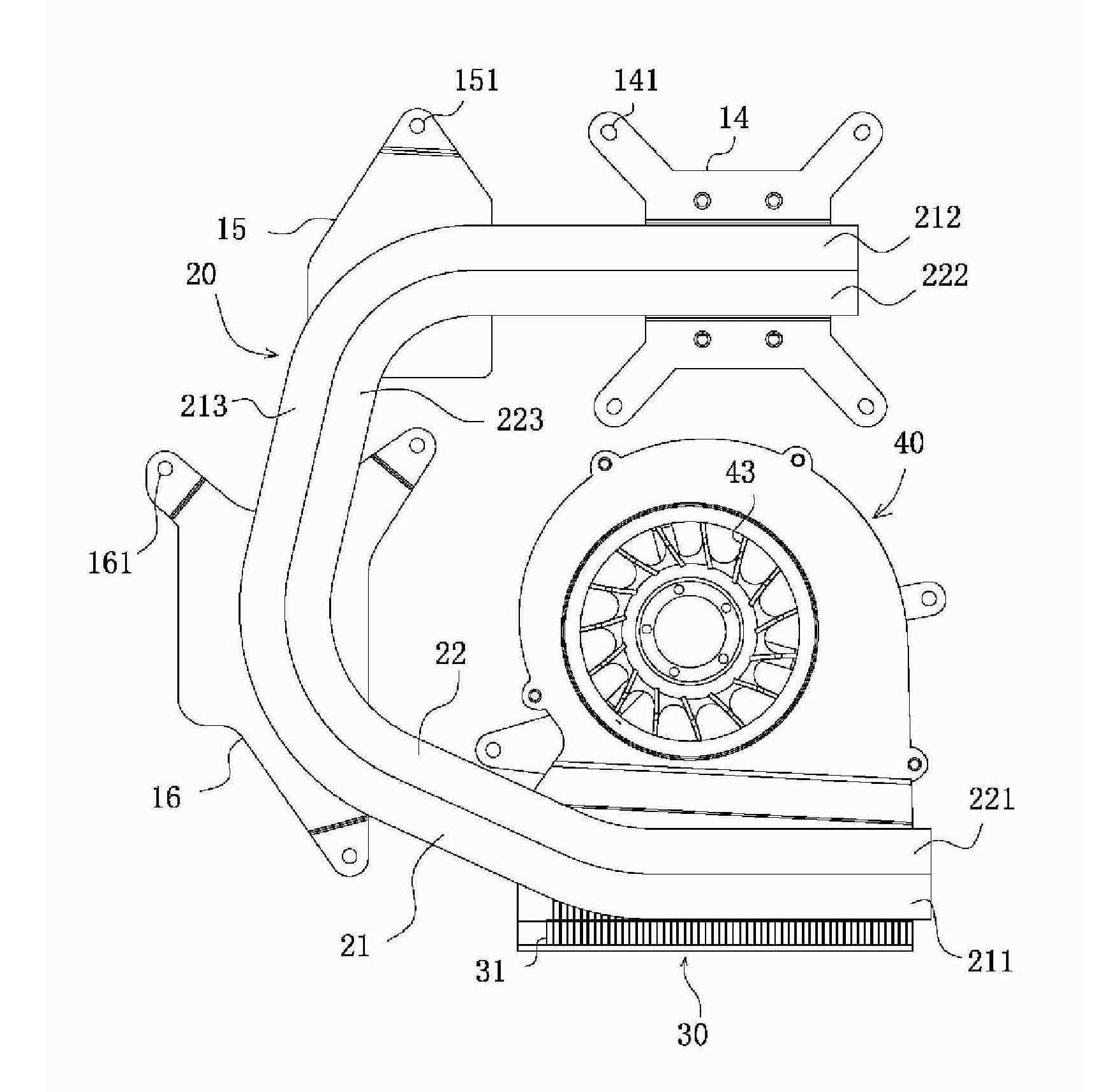

[0027] refer to Figure 1 to Figure 4 , the carbon nanomaterial heat dissipation module of the present invention includes at least one heat transfer module 10, at least one heat pipe 20, heat dissipation fin assembly 30 and heat dissipation fan 40, in this example, the heat transfer module 10 includes three heat transfer modules 11, 12, 13, they are respectively in contact with the south bridge chip, north bridge chip and CPU of the notebook computer in three heating devices, and the three heat transfer modules are made of carbon nanomaterials. The carbon nanomaterial is mixed with a graphite powder base material with a weight percentage content of 50% to 99% and a high thermal conductivity nanomaterial with a weight percentage content of 1% to 50%. In this example, the graphite powder base material The preferred w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com