Modified (methyl) acrylate resin and preparation method

A technology of methyl methacrylate and acrylate, which is applied in the field of multi-curable silicone modified (meth)acrylate resin and its preparation, can solve the problems of wear resistance and poor toughness, reduce brittleness, increase Flexibility, the effect of reducing curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of resin of the present invention comprises the following steps:

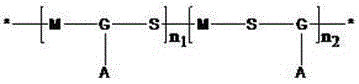

[0068] (1) Preparation of (meth)acrylate, glycidyl (meth)acrylate and silicone copolymer intermediates

[0069] Under the condition of passing inert gas, heat the solvent 1 to 60°C-90°C, slowly add the mixture of monomer 1, monomer 2, initiator, molecular weight regulator, and organosilicon containing double bonds, for 1 hour- The addition is completed in 6 hours; the system is kept warm for 2 hours to 10 hours, the temperature is raised to 100°C-130°C, and the temperature is kept for 0.5-4 hours to obtain a copolymer intermediate.

[0070] (2) Preparation of modified (meth)acrylate resin

[0071] Lower the temperature of the copolymer intermediate obtained in step (1) to below 60°C, pass air or other gases containing oxygen, add monomer 3, polymerization inhibitor, catalyst, then raise the temperature to 70°C-100°C, and keep it warm for 2 hours After -10 hours, the temperature o...

Embodiment 1

[0087] Synthesis of modified (meth)acrylate resin intermediates

[0088] In the reaction device equipped with a stirrer, condenser tube, nitrogen gas introduction tube, and thermometer, nitrogen gas is passed, 300 parts of butyl acetate are added, the temperature is raised to 80°C, the air in the reaction device is fully removed, and 300 parts of pre-configured Glycidyl methacrylate (hereinafter referred to as GMA), 75 parts of methyl methacrylate (hereinafter referred to as MMA), 37 parts of γ-methacryloxypropyl trimethoxysilane, 12 parts of azobisiso A mixed solution composed of butyronitrile (hereinafter referred to as AIBN) and 1.5 parts of lauryl mercaptan (hereinafter referred to as DDM) was slowly added dropwise for 3 hours and kept warm for 5 hours. Then, the mixture in the reaction device was blown into nitrogen. Raise the temperature to 120° C., keep the temperature for 2 hours, and cool down to obtain a modified (meth)acrylate resin intermediate.

[0089] Preparati...

Embodiment 2

[0092] Synthesis of modified (meth)acrylate resin intermediates

[0093] In the reaction device equipped with a stirrer, condenser tube, nitrogen gas inlet tube, and thermometer, nitrogen gas is passed, 300 parts of butyl acetate are added, the temperature is raised to 60°C, the air in the reaction device is fully removed, and 85.7 parts of pre-configured A mixed solution composed of GMA, 226 parts of MMA, 37 parts of γ-methacryloxypropyltrimethoxysilane, 12 parts of AIBN, and 1.5 parts of DDM was slowly added dropwise for 6 hours and kept warm for 2 hours. Then, the reaction device The mixture in the mixture was heated to 130° C. under the condition of feeding nitrogen gas, kept at a temperature of 0.5 hour, and cooled to obtain a modified (meth)acrylate resin intermediate.

[0094] Synthesis of modified (meth)acrylate resin

[0095] Cool the above resin intermediate to 60°C, blow in air, add the pre-configured 10.9 parts of AA, 0.4 parts of MEHQ, 0.5 parts of TPP mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com