Continuous feed and cutoff device of fibers

A cutting device and continuous technology, applied in the direction of transportation and packaging, metal processing, conveying filamentous materials, etc., can solve the problems of unsatisfactory composite materials, high production cost, low production efficiency, etc., achieve simple and convenient operation, and improve mechanization The effect of the degree of pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

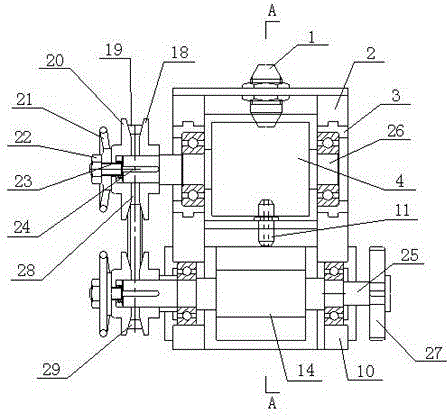

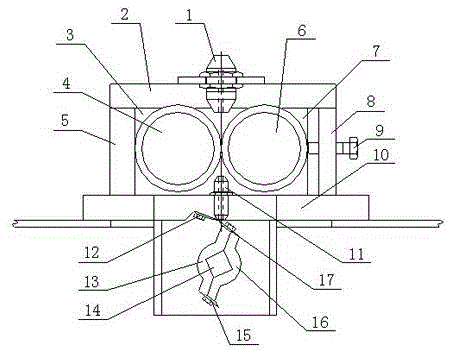

[0021] Such as figure 1 , figure 2 As shown, the present invention provides a continuous fiber feeding and cutting device, including a base 10, a first rotating shaft 25, and a second rotating shaft 26, wherein the second rotating shaft 26 is located above the first rotating shaft 25 and is connected to the first rotating shaft. The shafts 25 are parallel, and the first rotating shaft 25 and the second rotating shaft 26 are rotationally connected with the base 10 , wherein the rotation of the first rotating shaft 25 and the second rotating shaft 26 can be realized by setting a bearing on the base 10 . The left end of the second rotating shaft 26 is provided with a second infinitely variable transmission member 29, the right end of the first rotating shaft 25 is provided with a transmission wheel 27, and the left end of the first rotating shaft 25 is provided with a first continuously variable transmission member 28. A rotary cutter shaft 14 is provided, and the first continu...

Embodiment 2

[0031] Its general structure is the same or similar to that of the pipe sealer provided in Embodiment 1, so it will not be repeated here, and only the differences will be described below.

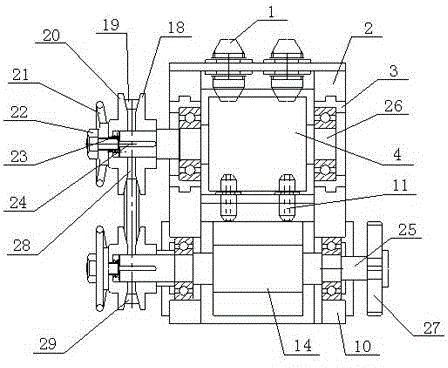

[0032] Such as image 3 A pair of wire inlet nozzles 1 and wire outlet nozzles 11 are provided in the first embodiment shown above, but in order to increase the feed rate, two pairs of wire inlet nozzles 1 and wire outlet nozzles 11 are provided in the second embodiment, so that the fiber feed mode is changed from Single-line feeding is changed to double-line feeding to meet the needs of production.

[0033] In the first and second embodiments above, there are one pair and two pairs of wire inlet nozzles 1 and wire outlet nozzles 11. In the actual production process, the number of wire inlet nozzles 1 and wire outlet nozzles 11 can be increased or decreased according to the needs of product production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com