Preparation method and application of novel hierarchical pore composite material

A composite material and multi-level pore technology, applied in alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of slow adsorption rate, high price, and low adsorption capacity, and achieve uniform pore size, Excellent thermal stability and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

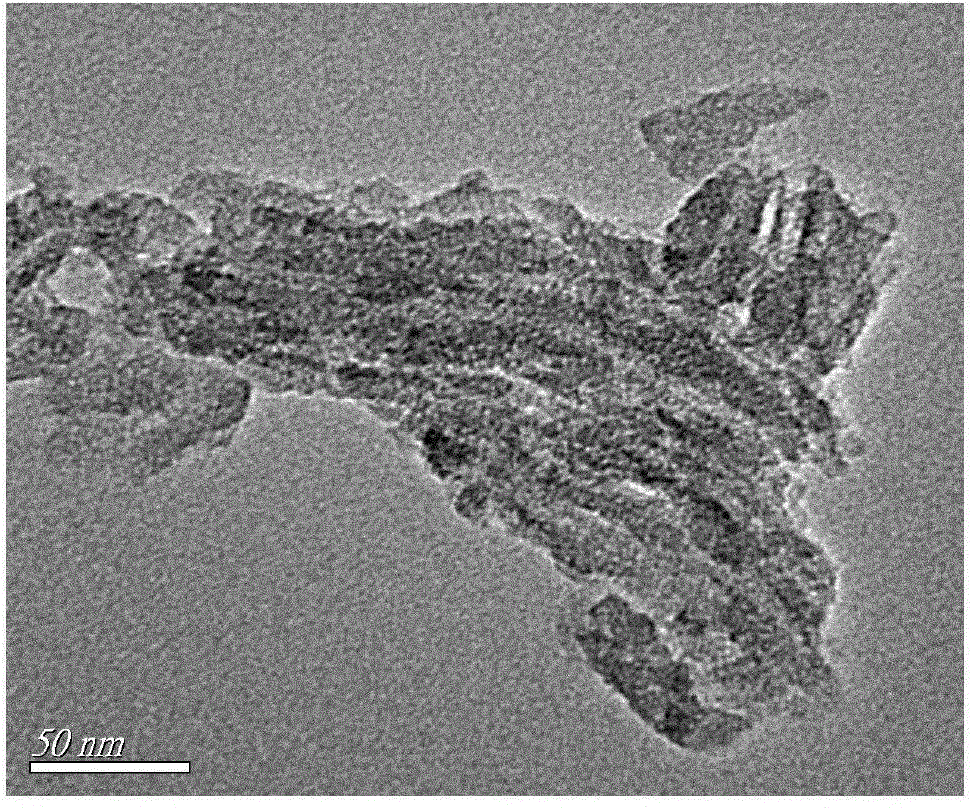

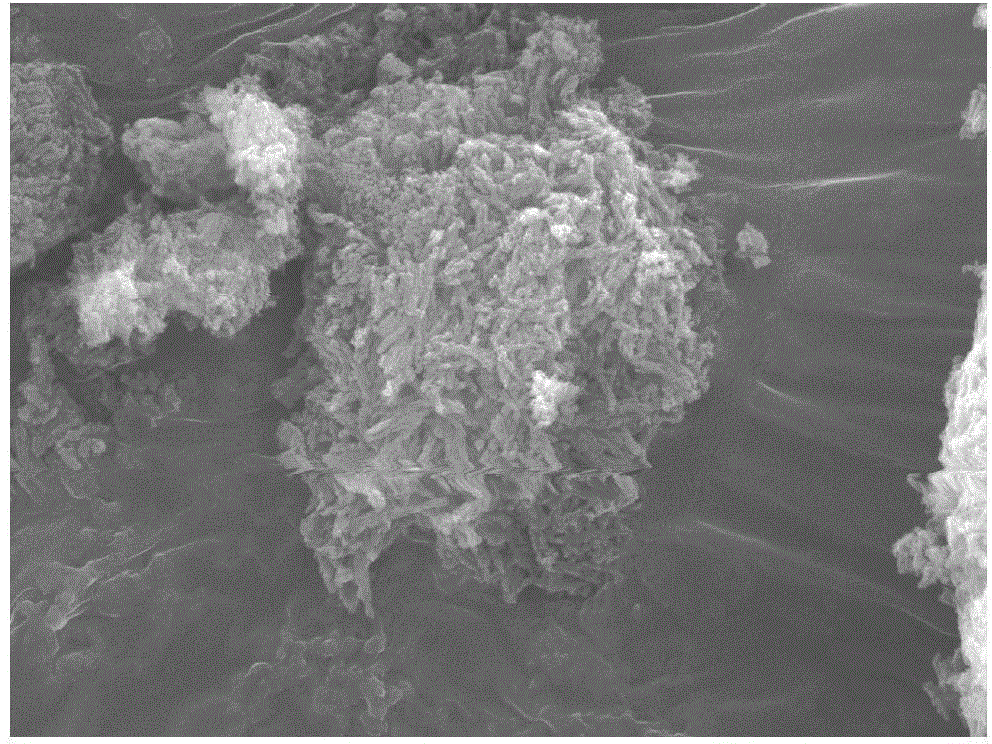

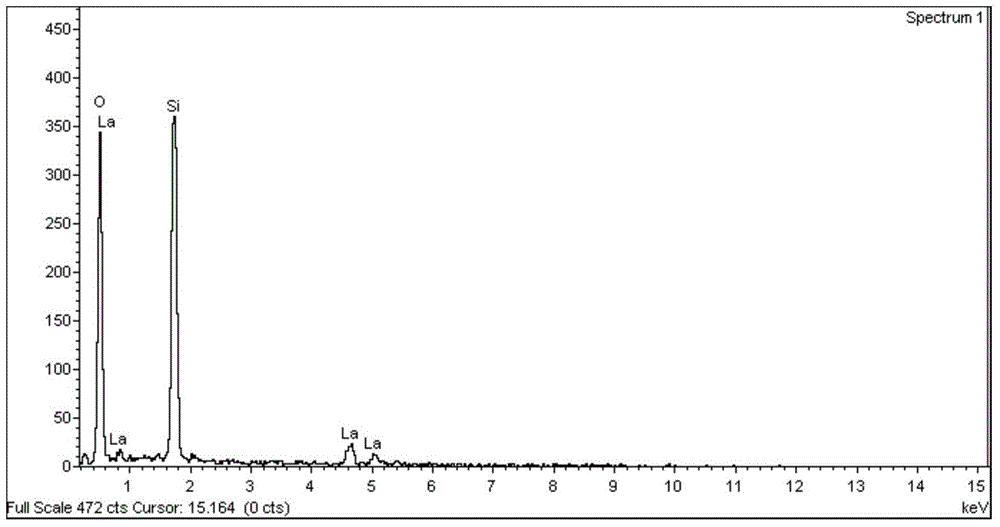

Image

Examples

Embodiment 1

[0027] (1) Dissolve 5.0g of absorbent cotton in 75ml of dilute sulfuric acid solution with a concentration of 45%, place it in a 45°C water bath at a constant temperature, keep mechanical stirring for 2 hours, dilute 10 times to 675ml, centrifuge at 4500r / min, and add Wash with distilled water until it cannot be centrifuged, and dialyze until the pH is 2.3 to obtain cellulose nanocrystals with a concentration of 3.5 wt%, which is diluted to 0.6 wt% by adding deionized water.

[0028] (2) Add 36ml of deionized water, 24ml of ethanol, and 25mg of CTAB into the round-bottomed flask, stir vigorously in a water bath at 30°C for 30min, then add 400ul of ammonia water, and add the diluted 0.6wt% cellulose nanocrystal obtained in step (1) 3.5ml, after stirring for 10min, add 80ul of tetraethyl silicate, and continue to keep the temperature in a water bath at 30°C for 2h.

[0029] (3) After the reaction in step (2) is completed, filter with suction, wash with deionized water and ethano...

Embodiment 2

[0032] (1) Dissolve 5.0g of absorbent cotton in 75ml of 50% dilute sulfuric acid solution, place it in a water bath at 45°C at constant temperature, keep stirring mechanically for 2 hours, dilute 10 times to 750ml, centrifuge at 5000r / min, and add distilled water to wash Until centrifugation fails, dialyze until the pH is 2.4 to obtain cellulose nanocrystals with a concentration of 3 wt%, which is diluted to 0.5 wt% by adding deionized water.

[0033] (2) Add 40ml of deionized water, 20ml of ethanol, and 30mg of cetyltrimethylammonium bromide (CTAB) to the round bottom flask, keep the temperature in a water bath at 30°C and stir vigorously for 30min, then add 500ul of ammonia water, and add the step ( 1) 4ml of the obtained diluted 0.5wt% cellulose nanocrystals was added, 100ul of tetraethyl silicate was added after 10min, and the temperature was kept constant in a 30°C water bath for 2h.

[0034] (3) After the reaction in step (2) is completed, filter with suction, wash with ...

Embodiment 3

[0049] (1) Dissolve 5.0g of absorbent cotton in 75ml of 55% dilute sulfuric acid solution, place it in a water bath at 45°C, keep mechanical stirring for 2h, dilute 10 times to 825ml, centrifuge at 5500r / min, and add distilled water to wash until Until centrifugation fails, the pH is adjusted to 2.5 by dialysis to obtain cellulose nanocrystals with a mass concentration of 2.5%, which is diluted to 0.4% by adding deionized water.

[0050] (2) Add 43ml of deionized water, 17ml of ethanol, and 35mg of cetyltrimethylammonium bromide (CTAB) into the round bottom flask, stir vigorously in a water bath at 30°C for 30min, then add 600ul of ammonia water, and add to step (1) After 4.5 ml of the obtained diluted 0.5 wt % cellulose nanocrystals, 120 ul of tetraethyl silicate was added after 10 min, and the water bath was continued at 30° C. for 2 h.

[0051] (3) After the reaction in step (2) is completed, filter with suction, wash with deionized water and ethanol three times, take it ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com