A Soilless Organic Waste Substrate Suitable for Raising Rubber Tree Seedlings

An organic waste, rubber tree technology, applied in planting substrates, soilless cultivation, organic fertilizers, etc., can solve problems such as the improvement of the quality of rubber seedlings that are unfavorable for field management operations, the destruction of farmland ecological environment, and the decline in ventilation and water-holding performance. It is convenient for production management, operation and out-of-plant transportation, low price and high SPAD value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The rubber tree soilless organic waste seedling raising substrate is formed by uniformly mixing cassava skin, bagasse ash and peanut shells in a volume ratio of 6:3:1. Wherein, the cassava skin is processed as follows: fresh cassava skin is stacked and retting in the open air, and urea is added according to 0.5-1% of its fresh weight, and the stacking time is 6 months. The bagasse ash was directly obtained from a local sugar factory, and the peanut shells were naturally stacked for 12 months in the open air.

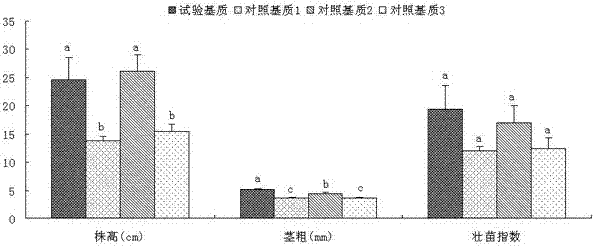

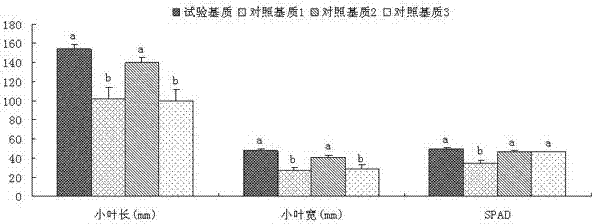

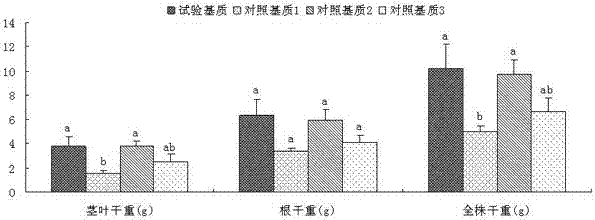

[0028] The above-mentioned rubber tree soilless organic waste seedling raising matrix of the present embodiment is carried out following rubber tree seedling raising matrix potted plant experiment research as test matrix:

[0029] Control matrix: the control matrix is the rubber seedling-raising matrix formula that has been screened out in the early stage with better application effects or used in production, wherein the control matrix 1 is made of garden soil, ...

Embodiment 2

[0039] The rubber tree soilless organic waste seedling raising substrate is formed by uniformly mixing cassava bark, bagasse ash and peanut shells at a volume ratio of 5:2:0.8. The processing of described cassava skin, bagasse ash, peanut shell is with embodiment 1.

[0040] The rubber tree soilless organic waste seedling raising substrate of the present embodiment is used as the test substrate to carry out the same rubber tree seedling raising substrate potting experiment research as in Example 1. The results show that the plant height of the rubber tree seedlings in the test substrate is the same as that in the contrast substrate 2 imported special peat for seedling cultivation. The plant height of the rubber seedlings was the same, and the plant height increased by 81.55% and 62.02% respectively compared with the control substrate 1 and 3 treatments; 9.09%, 6.07%; the seedling growth index of the rubber seedlings in the test medium was 12.20, which was lower than that of th...

Embodiment 3

[0042] The rubber tree soilless organic waste seedling raising substrate is formed by uniformly mixing cassava skin, bagasse ash and peanut shells in a volume ratio of 7:3:1. The processing of described cassava skin, bagasse ash, peanut shell is with embodiment 1.

[0043] The rubber tree soilless organic waste seedling raising substrate of the present embodiment is used as the test substrate to carry out the same rubber tree seedling raising substrate potting experiment research as in Example 1. The results show that the plant height of the rubber tree seedlings in the test substrate is the same as that in the contrast substrate 2 imported special peat for seedling cultivation. The plant height of the rubber seedlings was the same, and the plant height increased by 87.14% and 67.01% respectively compared with the control substrate 1 and 3 treatments. Compared with the control substrates 1, 2, and 3, the stem diameter of rubber seedlings increased by 28.12%, 1.34%, and 24.58%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com