Method for manufacturing thermoelectric converter

A technology of thermoelectric conversion and manufacturing method, which is used in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric devices using only Peltier or Seebeck effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

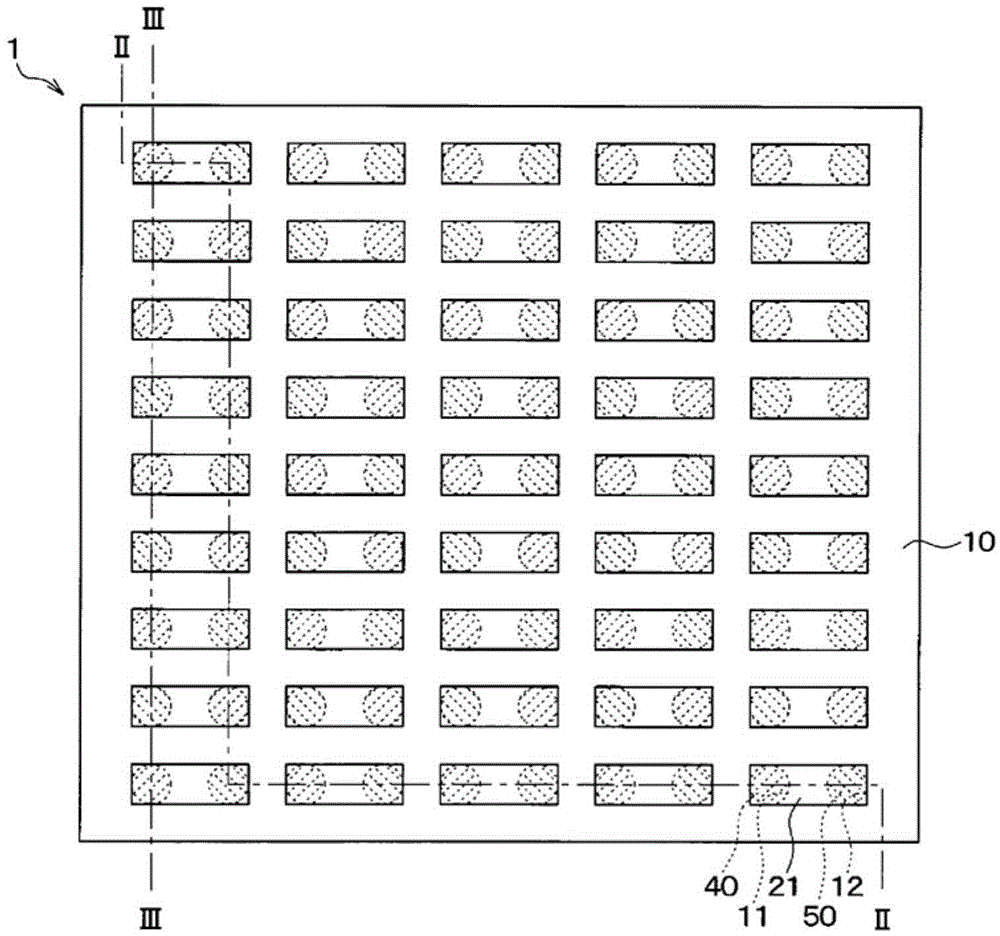

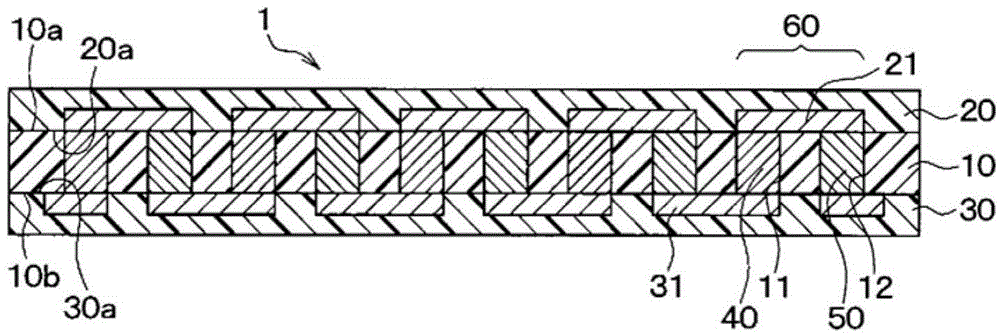

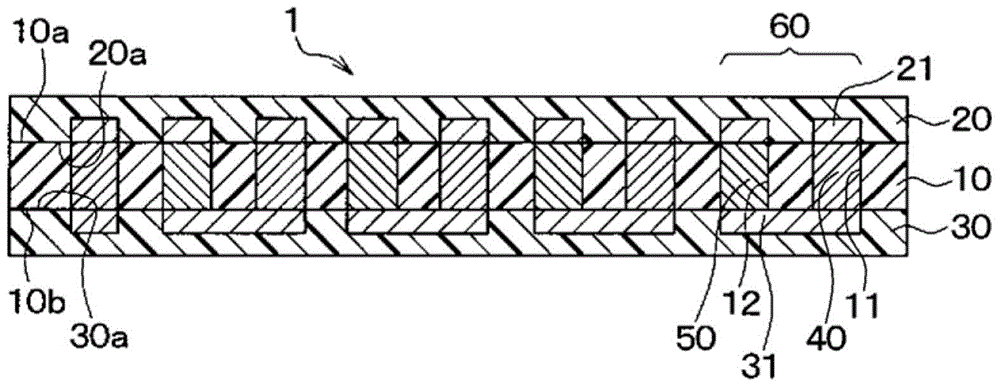

[0038] A first embodiment of the present invention will be described with reference to the drawings. Such as Figure 1 ~ Figure 3 As shown, the thermoelectric conversion device 1 of the present embodiment is constituted by integrating the insulating base material 10, the surface protection member 20, and the back surface protection member 30, and the first interlayer connecting member, which is a first interlayer connecting member, is a dissimilar metal inside the integrated member. 40. The second interlayer connection components 50 are alternately connected in series.

[0039] also, figure 1 For easy understanding, the surface protection member 20 is omitted and shown. in addition, figure 1 Although not a cross-sectional view, hatching is given to the first interlayer connection member 40 and the second interlayer connection member 50 .

[0040] In this embodiment, the insulating base material 10 is composed of a planar rectangular thermoplastic resin film made of polyeth...

no. 2 approach

[0080] A second embodiment of the present invention will be described. In this embodiment, compared with the first embodiment, the plated film is formed after the first interlayer connecting member 40 and the second interlayer connecting member 50 are formed. Since the rest is the same as the first embodiment, description is omitted here.

[0081] Such as Figure 8 As shown, in this embodiment, the Figure 4 After the step (e), a plated film 90 made of Ni or the like is formed on the portions of the first interlayer connecting member 40 and the second interlayer connecting member 50 exposed from the insulating base material 10 .

[0082] In addition, the parts of the first interlayer connecting member 40 and the second interlayer connecting member 50 exposed from the insulating base material 10 are, in other words, regions that are in pressure contact with the surface pattern 21 or the rear surface pattern 31 in the first embodiment. In addition, the plated film 90 is formed...

no. 3 approach

[0085] A third embodiment of the present invention will be described. In the present embodiment, the step of forming the through-hole in the insulating base material 10 is performed as compared with the first embodiment, and since the rest is the same as that of the first embodiment, description thereof will be omitted here.

[0086] Such as Figure 9 as well as Figure 10 As shown, in this embodiment, the Figure 4 After the step (d), the through-hole 13 corresponding to the void of the present invention is formed in the insulating base material 10 by a drill, a laser, or the like. In this embodiment, if Figure 9 as well as Figure 10 As shown, a plurality of cylindrical through-holes 13 separated at equal intervals are formed concentrically, that is, along the circumferential direction, with each of the first through-hole 11 and the second through-hole 12 as the center.

[0087] In addition, the case where the through-hole 13 is cylindrical is described here, but the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com