Integrated antenna provided with metal outer casing

A metal shell and antenna technology, which is applied to antenna equipment with additional functions and other directions, can solve the problems of ugly appearance, destroy the integrity of the metal shell, and cannot achieve the effect of metal appearance, and achieve improved aesthetic effects, wear resistance and aesthetics. effect, intensifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Generally, the metal casing that participates in radiation as part of the antenna in the communication device needs to be divided into multiple antenna parts, and the conduction between the antenna parts needs to be blocked to improve the performance of the antenna.

[0031] In this embodiment, the integrated metal shell antenna includes a complete metal shell 1, the material of the metal shell 1 is not limited here, aluminum alloy, magnesium aluminum alloy, stainless steel, carbon steel, alloy steel, iron, Any metal material such as copper or copper alloy; the production process of the metal shell 1 is also not limited, and can be any process such as milling, die-casting, forging, powder metallurgy, etc.

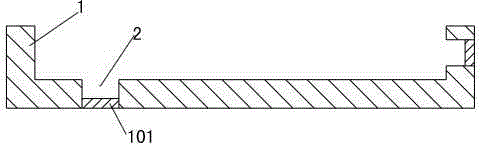

[0032] Such as figure 1 As shown in , on the inner surface of the metal shell 1, thin slots 2 are provided at the divisions of each antenna part, and the parts of the thin slots 2 are non-conductively treated; specifically, the bottom metal part 101 of the thin slot ...

Embodiment 2

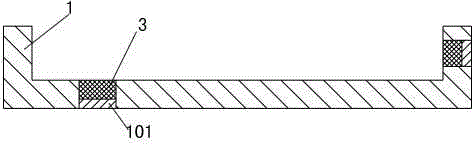

[0035] refer to figure 2 , this embodiment is a conversion embodiment of Embodiment 1. In this embodiment, a non-conductive body 3 may also be provided in the thin groove 2, and a non-conductive body 3 may be partially provided in the thin groove 2, or may be completely filled with non-conductive bodies. The conductor 3 is not limited here; the non-conductor 2 can specifically be made of materials such as plastics, and is arranged in the thin groove 2 through techniques such as nano-molding; the present invention provides reinforcement by setting the non-conductor 3 in the thin groove 2 The metal shell 1, the effect of preventing the corresponding position of the thin groove 2 from breaking.

[0036] For the structure of the remaining parts of the integrated metal case antenna provided in this embodiment, reference may be made to the relevant description in Embodiment 1, and details are not repeated here.

Embodiment 3

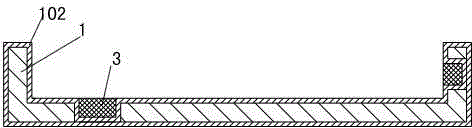

[0038] refer to image 3 , this embodiment is a modified embodiment of Embodiments 1 and 2. In this embodiment, all or part of the surface of the metal casing 1 is treated with non-conductive conduction, thereby forming a non-conductive layer 102 on the surface of the metal casing 1; In the present invention, the non-conductive treatment is carried out on the surface of the metal shell 1 , so as to improve the wear resistance of the metal shell 1 and improve the aesthetic effect of the metal shell 1 .

[0039] refer to Figure 4 , remove part of the non-conductive layer 102 on the inner surface of the metal case, thereby forming the connection point 4, so as to facilitate the conduction between the metal case antenna and other antenna devices.

[0040] For the structure of the rest of the integrated metal case antenna provided in this embodiment, reference may be made to the relevant descriptions in Embodiments 1 and 2, and details will not be repeated here.

[0041] To sum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com