Manufacturing method and application of Cr(VI) anion imprinted material

A technology of imprinting materials and anions, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of high-efficiency chromium anion selective recognition ability, high adsorption capacity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

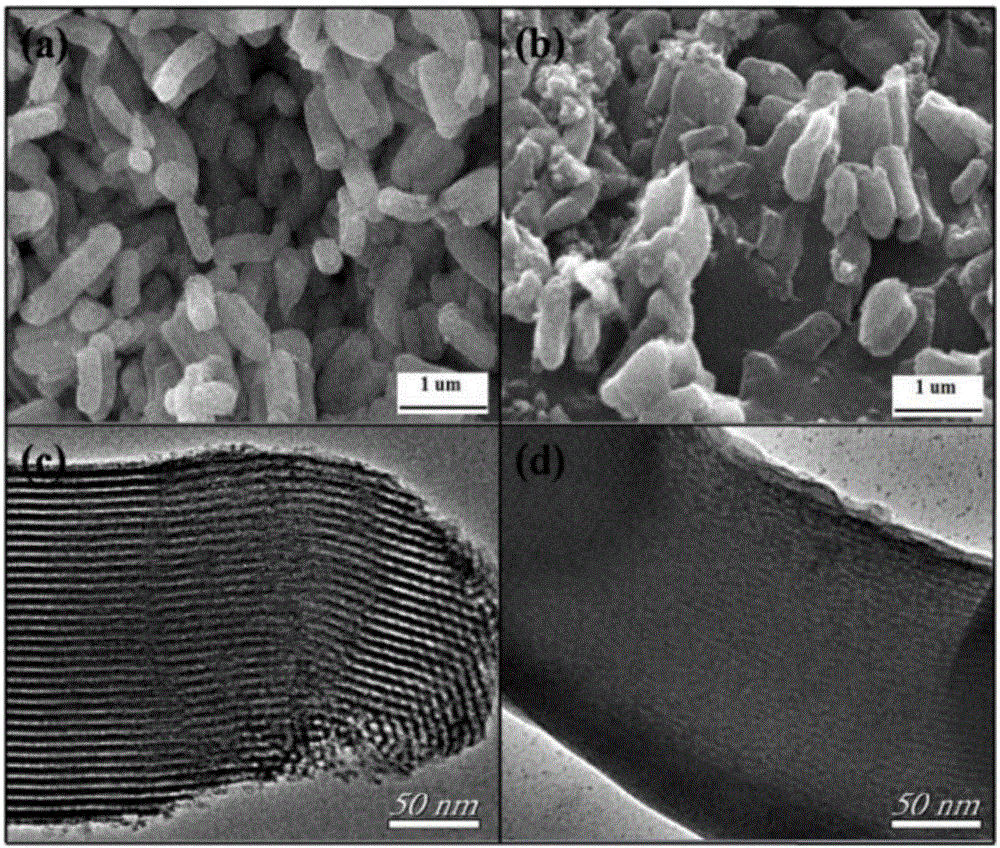

Image

Examples

Embodiment 1

[0044] (1) Take 0.05g of activated mesoporous silica (SBA-15) and add it to 50mL ethanol solution. After ultrasonic dispersion for 10min, add 2.5mL of methacryloxypropyl trimethoxysilane ( MPS), and the mixed solution was placed in a 50° C. water bath, and magnetically stirred for 12 h. The product was collected by centrifugation and washed three times with a large amount of ethanol to remove unreacted coupling agent MPS. After vacuum drying at 50°C, SBA-15 modified with methacryloxypropyltrimethoxysilane was obtained.

[0045] (2) Take 0.1g of SBA-15 modified by methacryloxypropyltrimethoxysilane and add 40mL of methanol and water mixed solution with a volume ratio of 3:1 to ultrasonically disperse for 10min, and add 36.8mg K 2 Cr 2 o 7 , 43 μL methacrylic acid (MAA) and 54 μL 4-vinylpyridine (4-VP). The mixed solution was placed in an oil bath at 25°C, and magnetically stirred for 2 hours to form a pre-assembled system. Pass N 2 After deoxygenation for half an hour, u...

Embodiment 2

[0057] (1) Take 0.1g of activated mesoporous silica (SBA-15) and add it to 50mL of ethanol solution, after ultrasonic dispersion for 10min, add 5mL of methacryloxypropyltrimethoxysilane (MPS ), and the mixed solution was placed in a 50° C. water bath, and magnetically stirred for 12 h. The product was collected by centrifugation and washed three times with a large amount of ethanol to remove unreacted coupling agent MPS. After vacuum drying at 50°C, SBA-15 modified with methacryloxypropyltrimethoxysilane was obtained.

[0058] (2) Take 0.1g of SBA-15 modified by methacryloxypropyltrimethoxysilane and add 40mL of methanol and water mixed solution with a volume ratio of 3:1 to ultrasonically disperse for 10min, and add 73.5mg K 2 Cr 2 o 7 , 86 μL MAA and 108 μL 4-VP. The mixed solution was placed in an oil bath at 25°C, and magnetically stirred for 2 hours to form a pre-assembled system. Pass N 2 After deoxygenation for half an hour, 10 mmol EGDMA and 10 mg AIBN were adde...

Embodiment 3

[0070] (1) Take 0.2g of activated mesoporous silica (SBA-15) and add it to 50mL of ethanol solution, after ultrasonic dispersion for 10min, add 10mL of methacryloxypropyltrimethoxysilane (MPS ), and the mixed solution was placed in a 50° C. water bath, and magnetically stirred for 12 h. The product was collected by centrifugation and washed three times with a large amount of ethanol to remove unreacted coupling agent MPS. After vacuum drying at 50°C, SBA-15 modified with methacryloxypropyltrimethoxysilane was obtained.

[0071] (2) Take 0.1g of SBA-15 modified by methacryloxypropyltrimethoxysilane and add 40mL of methanol and water mixed solution with a volume ratio of 3:1 to ultrasonically disperse for 10min, and add 147mg K to the solution respectively 2 Cr 2 o 7 , 172 μL MAA and 216 μL 4-VP. The mixed solution was placed in an oil bath at 25°C, and magnetically stirred for 2 hours to form a pre-assembled system. Pass N 2 After deoxygenation for half an hour, under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic adsorption capacity | aaaaa | aaaaa |

| Dynamic adsorption capacity | aaaaa | aaaaa |

| Dynamic adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com