Wastewater nitrogen and phosphorus removing method based on magnesite

A technology for denitrification, phosphorus removal, and magnesite, which is applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of electroplating waste water, waste water water quality is as shown in table 1.

[0033] Table 1 Water quality of electroplating wastewater

[0034]

[0035] A kind of magnesite-based wastewater denitrification and dephosphorization method of the present embodiment, its steps are:

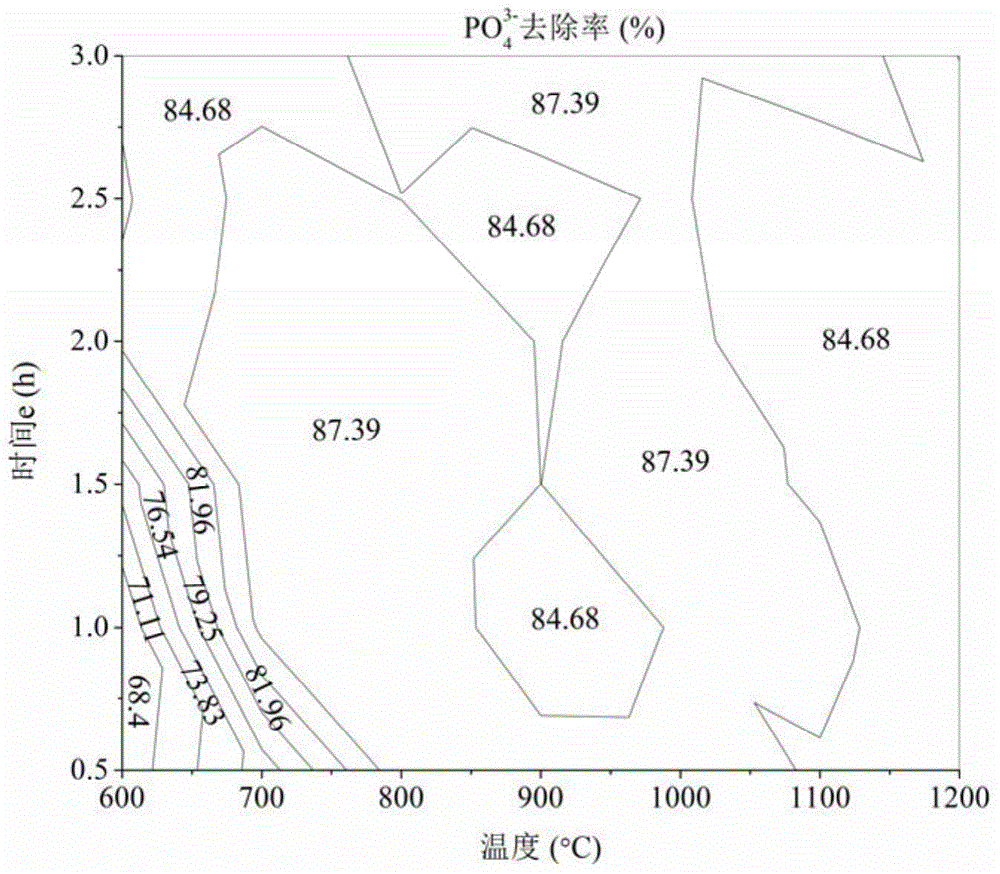

[0036] (1) Magnesite ore was purchased from Yingkou, Liaoning, crushed through a 100-mesh sieve, and calcined at 600-1200°C for 0.5h-3.0h to obtain a calcined product;

[0037] (2) add the calcined product that step (1) makes in waste water (the pH value of waste water is 0.62), the mol ratio of calcined product and phosphate in waste water is 0.9:1, and the magnetic stirring time is 10min, and magnesite ore dissolves The pH of the post-mix liquid is 7.2;

[0038] (3) Add ammonium chloride to the stirred waste water in step (2), the mol ratio of ammonium chloride and phosphate is 1:1, and the mol ratio with calcined product (calcined product is calculated by 100% magnesium oxide...

Embodiment 2

[0043] A chemical industry wastewater, wastewater quality see Table 2.

[0044] Table 2 Water quality of a chemical industry wastewater

[0045]

[0046] A kind of magnesite-based wastewater denitrification and dephosphorization method of the present embodiment, its steps are:

[0047] (1) Magnesite ore was purchased from Yingkou, Liaoning, crushed through a 100-mesh sieve, and calcined at 800°C for 1.5h to obtain a calcined product;

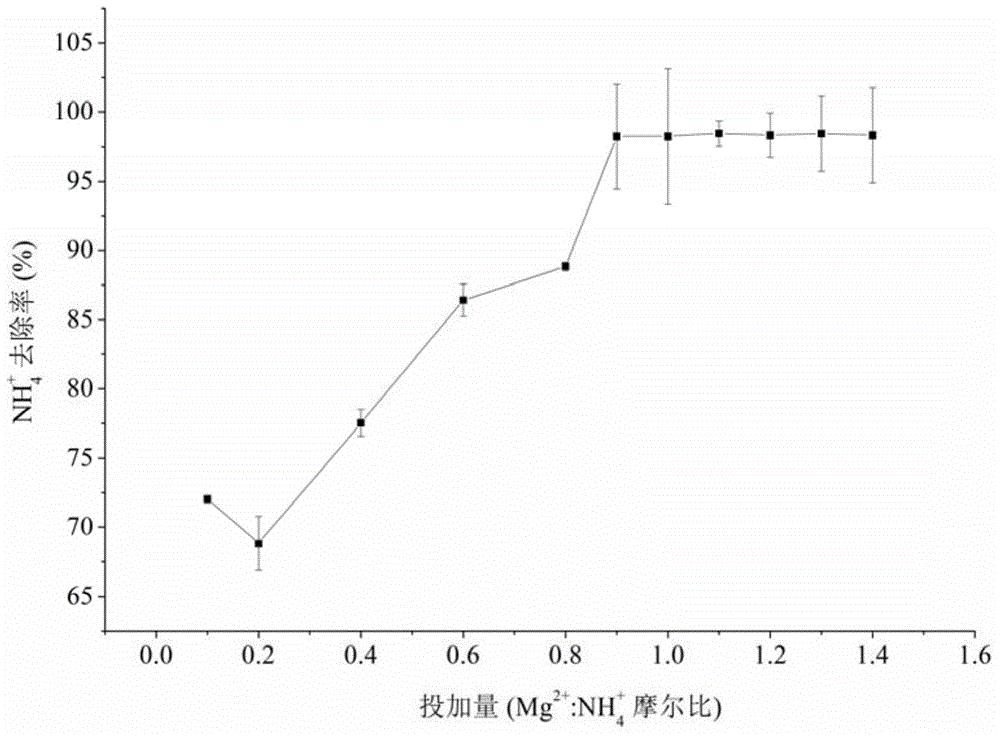

[0048] (2) Add the calcined product obtained in step (1) to the waste water, the molar ratio of the calcined product to ammonia nitrogen in the waste water is 0.2:1~1.6:1, magnetically stir for 10min, and the pH of the mixed liquid after the magnesite is dissolved is 4.0 ~8.5;

[0049] (3) Add sodium dihydrogen phosphate to the stirred wastewater in step (2), the molar ratio of ammonia nitrogen and phosphate in the wastewater is 1:1, adjust the pH to 9.5 with sodium hydroxide, stir for 30 minutes, and let stand for 30 minutes , forming mag...

Embodiment 3

[0054] A chemical industry wastewater, the wastewater quality is shown in Table 3.

[0055] Table 3 Water quality of a chemical industry wastewater

[0056]

[0057] A kind of magnesite-based wastewater denitrification and dephosphorization method of the present embodiment, its steps are:

[0058] (1) Magnesite ore was purchased from Yingkou, Liaoning, crushed through a 100-mesh sieve, and calcined at 900°C for 1 hour to obtain a calcined product;

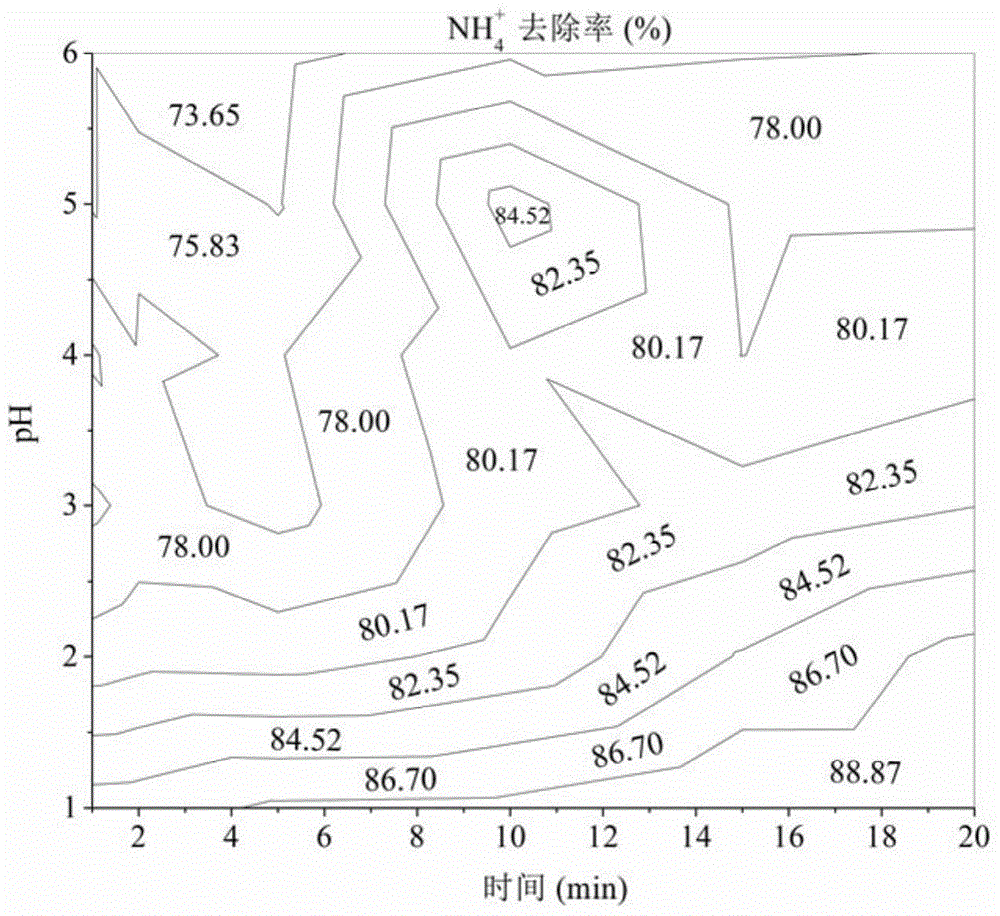

[0059] (2) Regulate the pH value of waste water to 1~6 with hydrochloric acid, then add the calcined product that step (1) makes in waste water, the mol ratio of calcined product and ammonia nitrogen in waste water is 0.9:1, magnetic stirring 1min~20min, After the magnesite ore is dissolved, the pH of the mixed liquid is 7-9;

[0060] (3) add sodium dihydrogen phosphate in the waste water after stirring in step (2), the mol ratio of ammonia nitrogen and phosphate in the waste water is 1:1, and the mol ratio with calcined produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com