Preparation technology of crack-free titanium hydride electrode source sheet

A preparation process, a technology of titanium hydride, applied in the direction of transition element hydride, etc., can solve the problems of shortened service life, electrode source plate bursting, etc., and achieve the effects of prolonging life, improving uniformity, and economical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

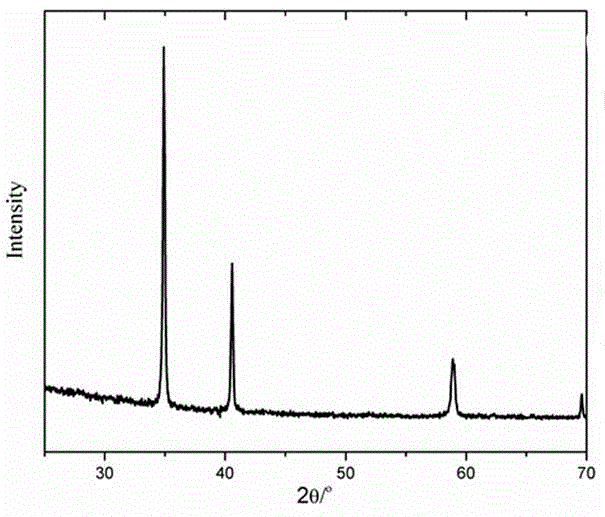

Image

Examples

Embodiment

[0039] The preparation process of a non-crack titanium hydrogenation electrode source sheet of the present invention adopts Goodfellow TI007930 pure titanium rod as raw material, and produces according to the following process:

[0040] (a1) Process pure titanium into a pure titanium source piece with a diameter of 6.05mm and a thickness of 0.58mm;

[0041] (a2) Perform mechanical grinding and polishing, using Al 2 o 3 Grind the powder as grinding powder in a laboratory small ball mill for 20 minutes;

[0042] (a3) Wash the ground electrode source sheet with deionized water, soak it in 60°C sodium hydroxide solution for 5 minutes, take it out and wash it with deionized water, put it in hydrofluoric acid solution for 5 minutes, take it out and use it again After cleaning with deionized water, put it into alcohol and sonicate for 5 minutes;

[0043] (a4) Take it out and put it in the dryer for drying. Use the METTLER TOLEDO XS205 balance to weigh the electrode source sheet. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com