Thermal-insulation and temperature-adjustment lining

A technology of lining and temperature adjustment, applied in lamination, layered products, microcapsule preparations, etc., can solve the problems of low effective content of phase change materials, influence of thermal insulation effect, damage of ordinary materials, etc., to reduce heat loss , Excellent tactility, extended functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

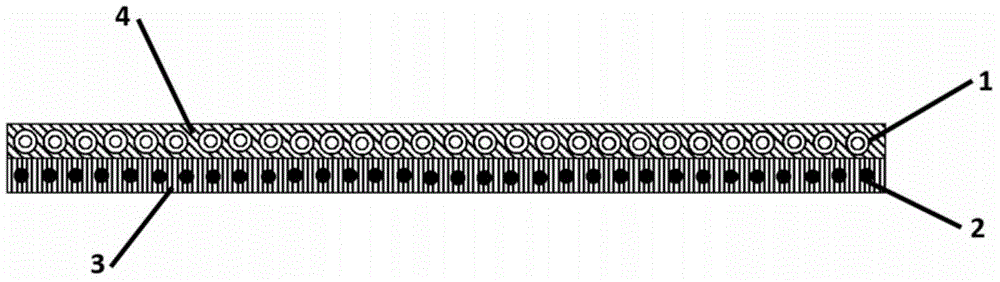

Image

Examples

Embodiment 1

[0039] A heat-insulating and temperature-regulating lining, the preparation method of which is as follows:

[0040] (1) Mix the dry powder of the phase change material and the PU glue evenly, and the mass percentage of the dry powder of the phase change material is 5-15%. In this embodiment, the dry powder of the phase change material has a phase change temperature of 31°C. For the preparation method, refer to this patent The "Microcapsule Energy Storage Composition and Its Preparation Method" (Application No.: 201410401132.5) was invented by Renren series, which was solidified into polymer film A by film calendering process;

[0041] (2) Add 3g resorcinol and 5g formaldehyde to 5g deionized water to form an aqueous phase solution, add 10g of span80 to 100ml cyclohexane, stir to form an inverse emulsion, heat up to 80°C, and react for 90min , obtain phenolic resin hollow microspheres after filtering and drying;

[0042] (3) After uniformly mixing the phenolic resin hollow mic...

Embodiment 2

[0046] A heat-insulating and temperature-regulating lining, the preparation method of which is as follows:

[0047] (1) Mix the dry powder of the phase change material and the PU glue evenly, and the mass percentage of the dry powder of the phase change material is 5-10%. In this embodiment, the dry powder of the phase change material has a phase change temperature of 31°C. For the preparation method, refer to this patent The "Microcapsule Energy Storage Composition and Its Preparation Method" (Application No.: 201410401132.5) was invented by Renren series, which was solidified into polymer film A by film calendering process;

[0048] (2) Mix the dry powder of the phase change material and the PU glue evenly, wherein the mass percentage of the dry powder of the phase change material is 5-10%. In this embodiment, the dry powder of the phase change material has a phase change temperature of 35°C. For the preparation method, refer to this patent The "Microcapsule Energy Storage C...

Embodiment 3

[0054] A heat-insulating and temperature-regulating lining, the preparation method of which is as follows:

[0055] (1) Mix the dry powder of the phase change material and the PU glue evenly, and the mass percentage of the dry powder of the phase change material is 5-15%. In this embodiment, the dry powder of the phase change material has a phase change temperature of 31°C. For the preparation method, refer to this patent The "Microcapsule Energy Storage Composition and Its Preparation Method" (Application No.: 201410401132.5) was invented by Renren series, which was solidified into polymer film A by film calendering process;

[0056] (2) Add 3 g of cresol and 6 g of conaldehyde to 10 g of deionized water to form an aqueous phase solution, add 10 g of span80 to 100 ml of liquid paraffin, stir to form an inverse emulsion, heat up to 80 ° C, and react for 90 min. Obtain phenolic resin hollow microspheres after filtering and drying;

[0057] (3) After uniformly mixing the phenol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com