Full-automatic rubber production equipment

A production equipment and fully automatic technology, applied in metal processing and other directions, can solve the problems of low production efficiency, high production cost, and many manpower, etc., and achieve the effect of high production efficiency, low production cost, and low consumption of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

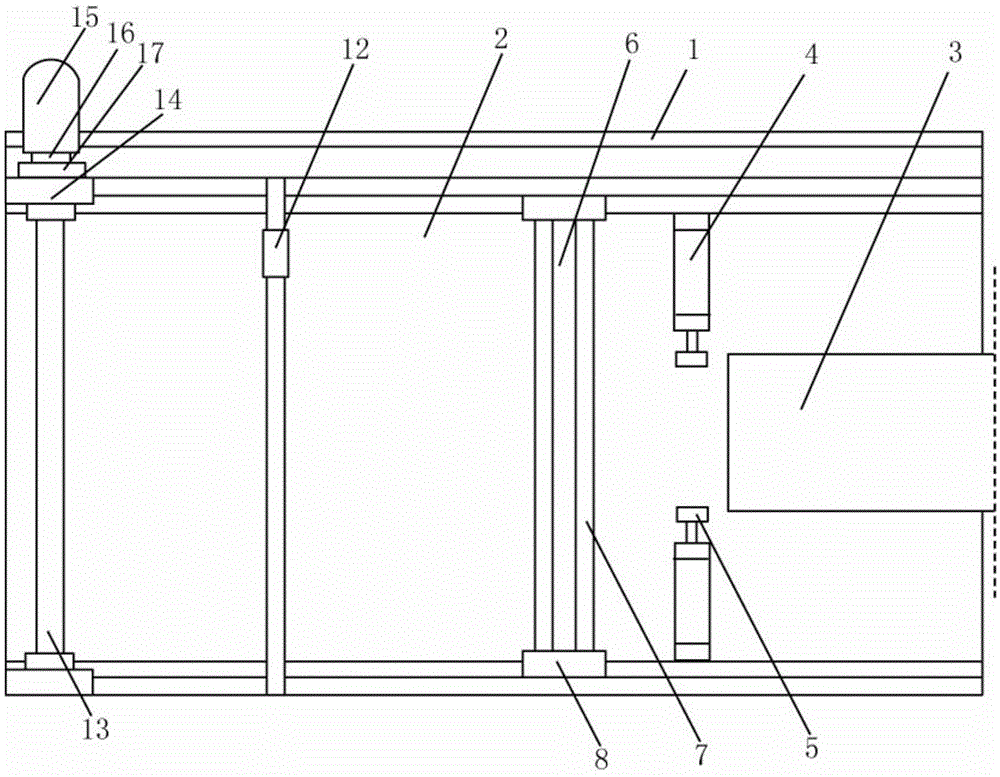

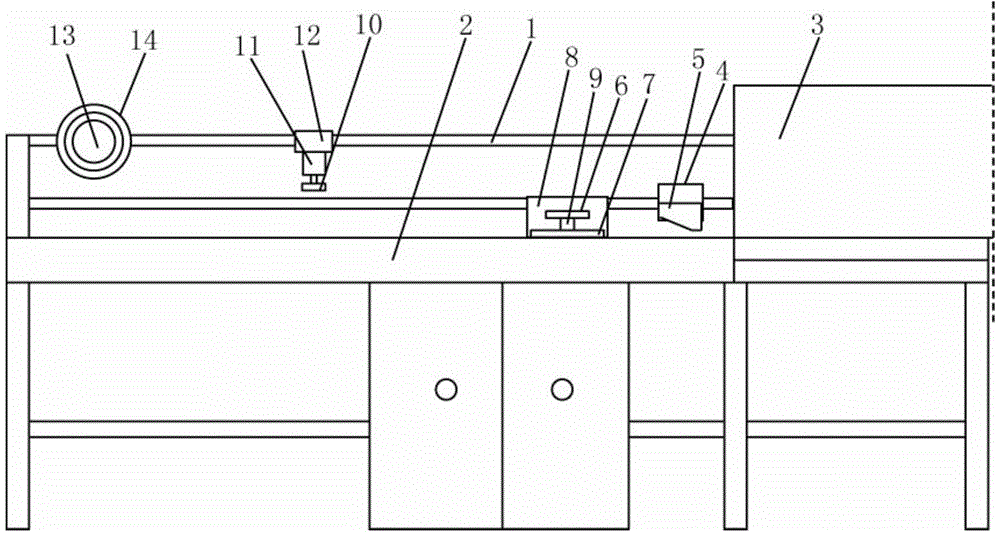

[0024] Such as Figure 1-2 As shown, a fully automatic rubber production equipment includes a frame 1, a machine table 2, a rubber extrusion molding machine head 3, a cutter cylinder 4, a trimming cutter 5, an upper splint 6, a lower splint 7, and a sliding splint Mechanism 8, splint cylinder 9, cut-off cutter 10, cut-off cutter cylinder 11, cutter sliding mechanism 12, reel 13, reel holder 14, reel motor 15, machine 2, rubber extrusion molding machine head 3 Fixed on the frame 1 and the machine table 2 is located in front of the head 3 of the rubber extrusion molding machine, the cutter cylinder 4, the trimming cutter 5, the upper splint 6, the lower splint 7, the splint sliding mechanism 8, the splint cylinder 9, The cutting knife 10, the cutting knife cylinder 11, the knife sliding mechanism 12, the winding shaft 13, the winding shaft fixing seat 14, and the winding shaft motor 15 are located above the machine 2, and the rear end of the cutting knife cylinder 4 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com