Ultrasonic drilling machine

A technology of ultrasonic wave and drilling machine, which is applied in the direction of drilling/drilling equipment, turning equipment, stone processing equipment, etc., to achieve the effect of strong three-dimensional sense, excellent practical performance and beautiful lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

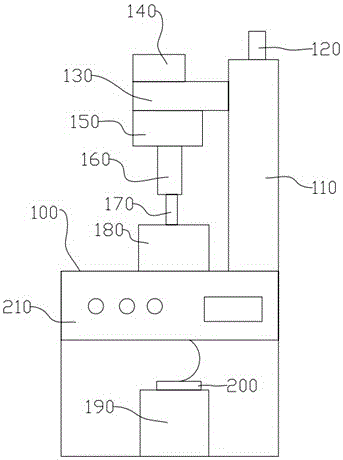

[0014] see figure 1 , one An ultrasonic punching machine includes a work surface 100, a steel column 110 is installed on one side of the work surface 100, a lifting handwheel 120 is arranged on the top of the steel column 110 to control the expansion and contraction of the steel column, and a wave head is installed on the connecting rod of the steel column 110. The installation barrel 130 is provided with a cooling fan 140 at the top of the wave head installation barrel 130, and a locking mechanism 150 is arranged at the bottom of the wave head installation barrel 130. The locking mechanism 150 is connected to the tool head 170 through the ultrasonic horn 160. A water tank 180 is provided below, and an ultrasonic generator panel 210 is mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com