Servo-type multi-position turntable and its precision characteristic testing device

A multi-station, servo-type technology, used in measuring devices, workbenches, feeding devices, etc., can solve the measurement that pays less attention to dynamic characteristics, can not meet the measurement requirements of the new multi-station turntable device accuracy characteristics, low operating accuracy, etc. problem, to achieve the effect of small transmission error, improved positioning accuracy, and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

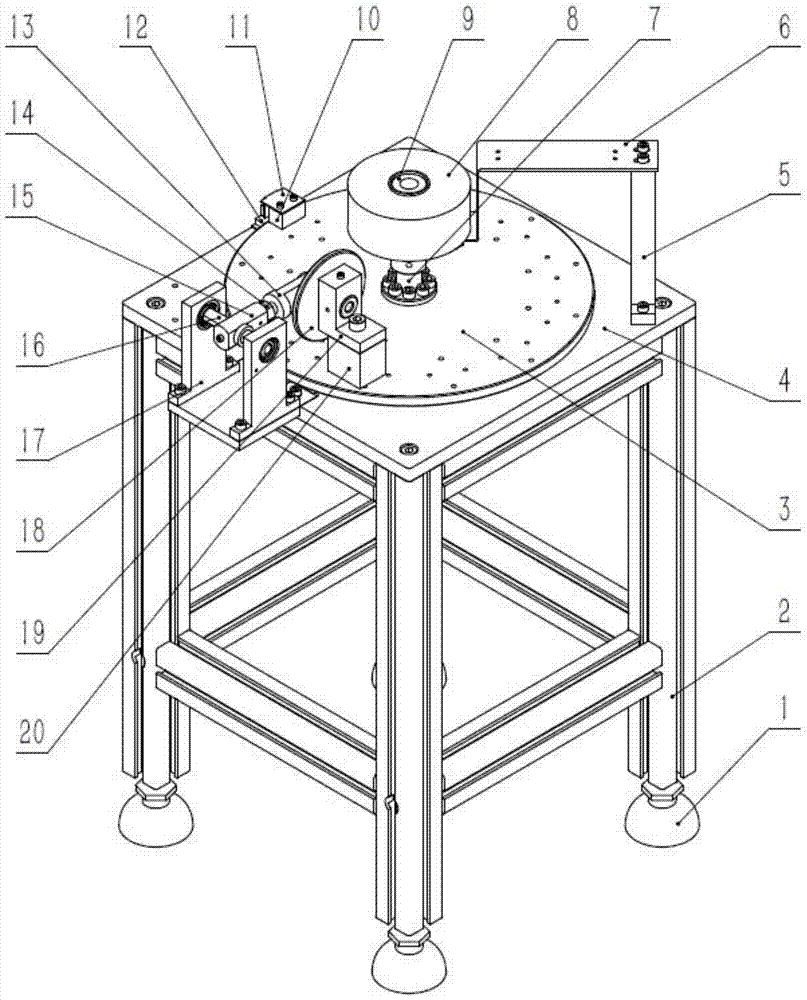

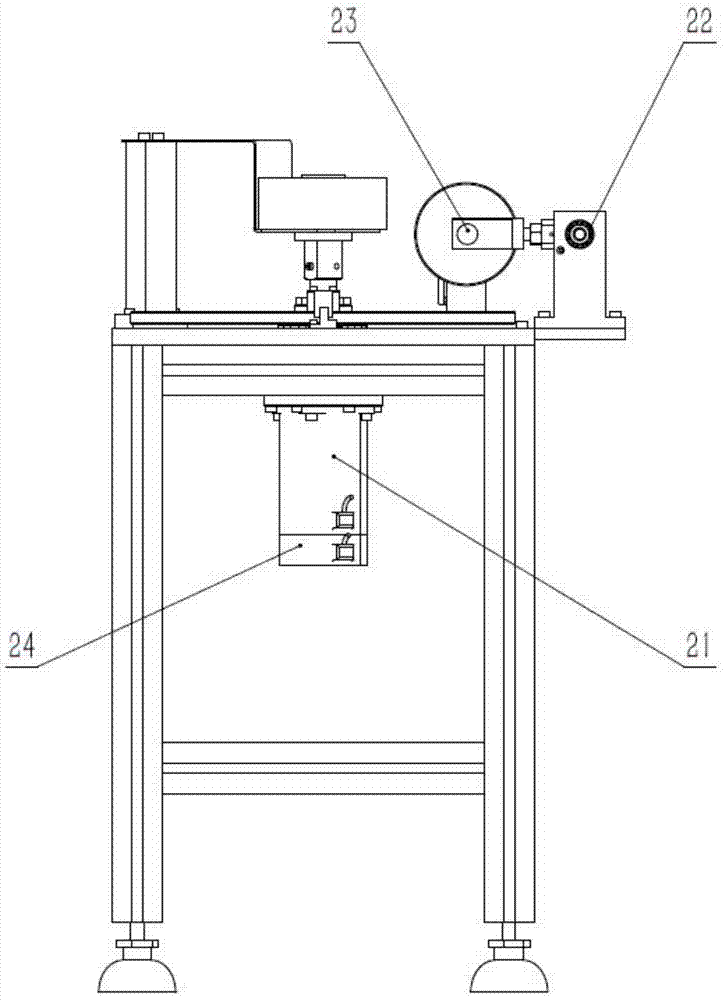

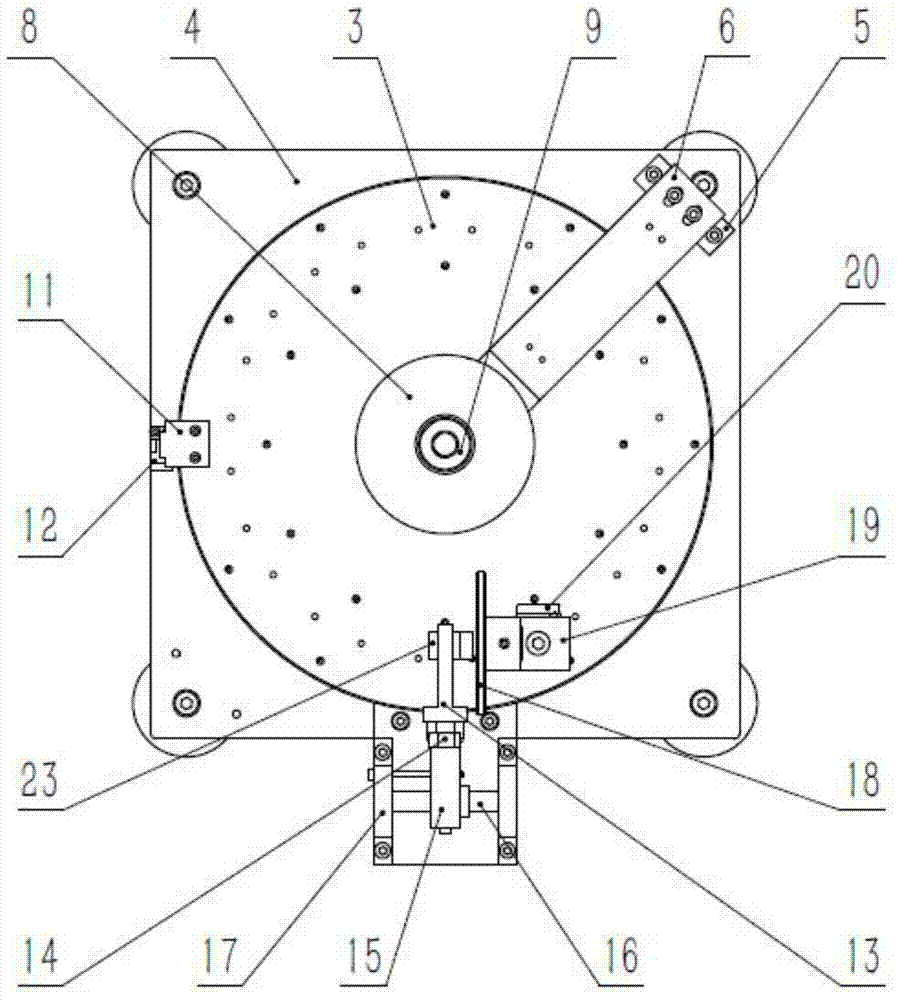

[0045] The servo-type multi-station turntable and its accuracy characteristic testing device of this embodiment are as follows: Figure 1-8 As shown, the device includes a frame and a fixed plate set on the frame, a harmonic reducer, a servo motor, a cross roller bearing, a multi-station turntable, a flange shaft, and an angle encoder mounted on the flange shaft device, an eddy current displacement sensor measuring device installed on a fixed plate, a target panel device, an origin reset device, and a control and detection circuit. The frame includes ground feet 1, aluminum profiles 2 and connectors; the harmonic reducer is composed of a steel wheel 27, a flexible spline 30 and a wave generator 26; the eddy current displacement sensor testing device includes a sensor probe 23, a first rotating arm 13, Second rotating arm 15, locking nut 14, rotating shaft 16, bearing 22 and bearing 17; Target panel device comprises target plate 18, L-shaped connector 19 and the magnetic force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com