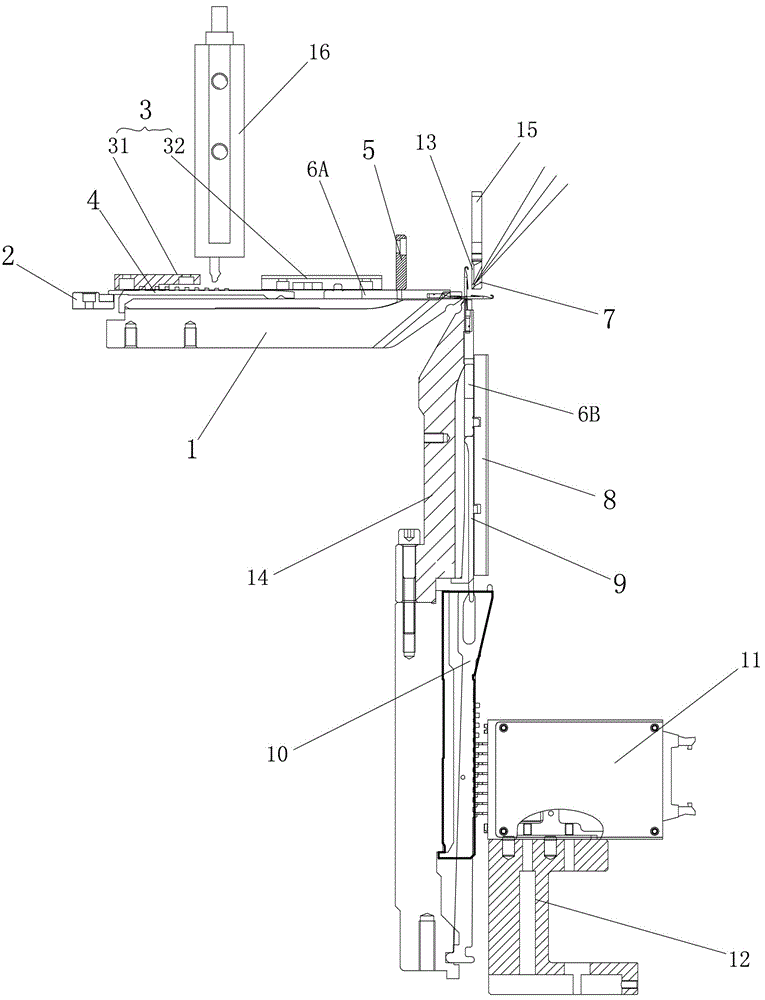

Vertical loop-transferring jacquard control mechanism of round knitting machine

A control mechanism and circular knitting machine technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of short service life, easy slipping, damage to knitting needles, etc., achieve long service life, small transmission error, Good fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

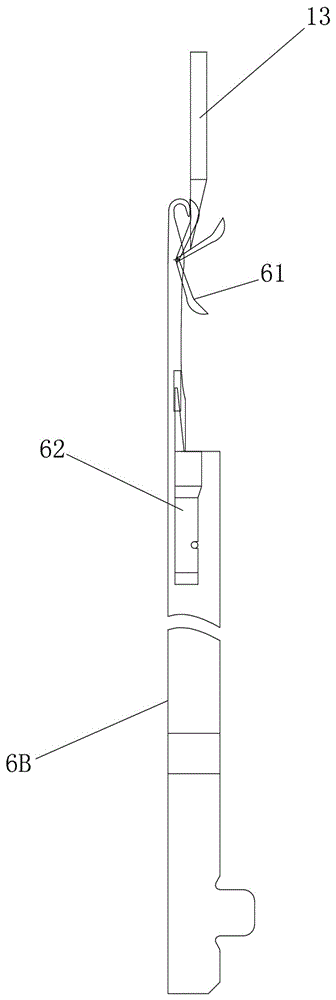

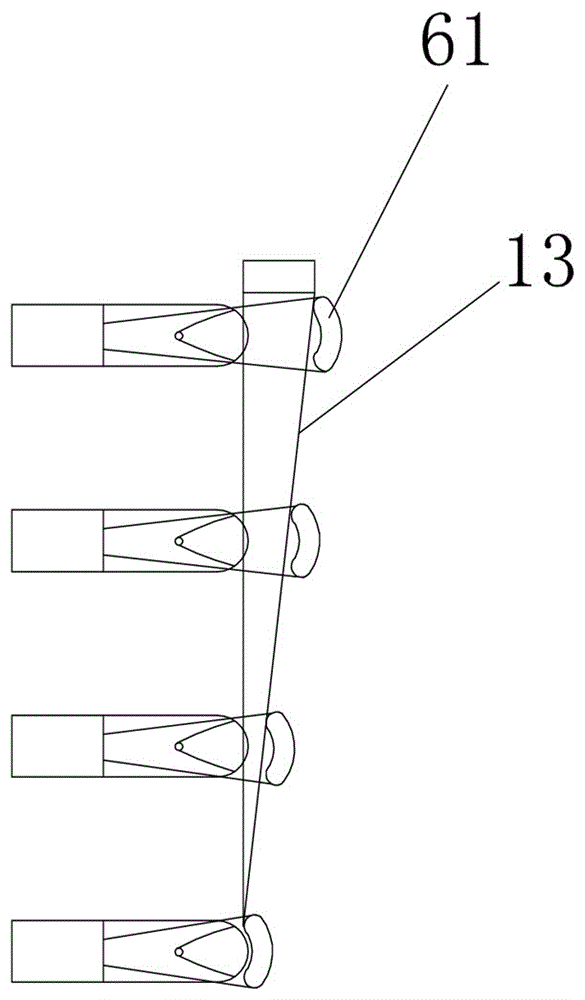

[0026] Such as Figure 1 to Figure 6 As shown, a circular knitting machine up and down loop transfer jacquard control mechanism, including the upper needle selection mechanism, the lower needle selection mechanism, tongue opening mechanism, the upper needle selection mechanism includes the upper dial 1, the reset cam assembly 2, the upper loop transfer working cam Component 3, upper jacquard piece 4, upper knitting needle 6A, upper needle selector 16, several needle grooves arranged radially on the upper end surface of upper dial 1, each needle groove is provided with an upper jacquard sheet 4 and an upper knitting needle 6A, and the front end surface of the upper jacquard sheet 4 is in contact with the rear end surface of the upper knitting needle 6A to form a working surface, and the face-to-face contact can make the upper jacquard sheet 4 and the upper knitting needle 6A are docked and working at the same time, the upper knitting cam assembly 3 is correspondingly arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com