Manufacture method and structure of TFT substrate

A manufacturing method and substrate technology, applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of image flicker coupling voltage response time, charging rate deviation, liquid crystal capacitance and storage capacitance deviation from simulation results, and thickness reduction. To achieve the effect of shortening the production cycle, reducing risks and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0061] see Figure 7 , the present invention at first provides a kind of manufacture method of TFT substrate, comprises the following steps:

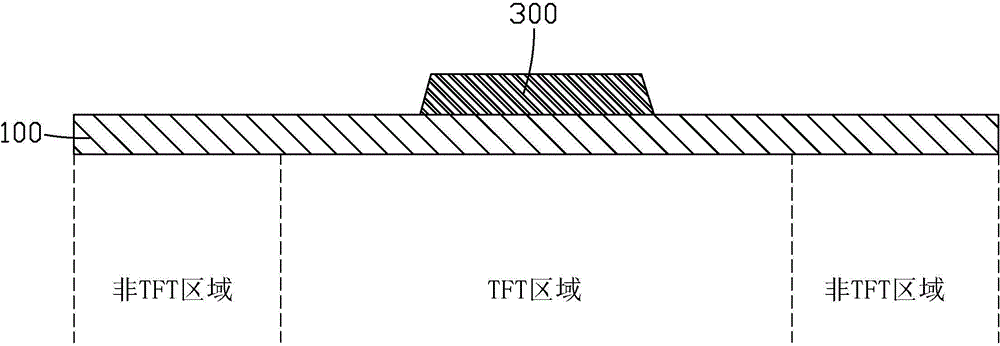

[0062] Step 1, such as Figure 8 As shown, a substrate 1 is provided, and a TFT region and a non-TFT region are provided on the substrate 1; a first metal layer is deposited on the substrate 1, and the first metal layer is patterned by a photolithography process to form a Gate 3 in the middle of the TFT area.

[0063] Specifically, in step 1, the physical vapor deposition method is used to deposit the first metal layer, and the material of the first metal layer is copper, aluminum, or molybdenum.

[0064] Step 2, such as Figure 9 As shown, a gate insulating layer 4 , an amorphous silicon layer 51 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com