External gate-controlled cold cathode array electron gun

An external, cold cathode technology, which is applied to electron/ion guns of time-of-flight electron tubes, time-of-flight electron tubes, circuits, etc., can solve the problem of easy mixing of metal shavings or impurities, the presence of current on the surface of the medium, and the inability to generate large Current and other issues, to improve the effect of electron convergence, improve stability, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

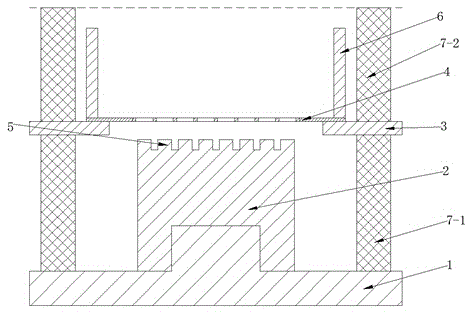

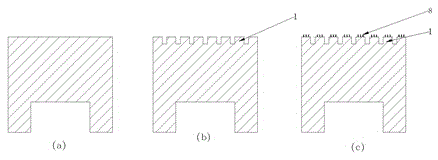

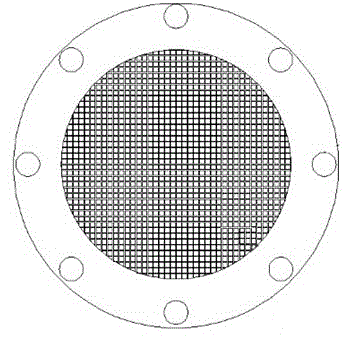

[0031] Such as Figures 1 to 4As shown, this embodiment provides an external grid-controlled cold cathode array electron gun, which mainly includes a cathode base 1, a cathode substrate 2, a cold cathode emitting unit array 5, an electron gun shell, an external grid 4 and other components; The cathode electron source array of the electron gun can be made into various specifications according to requirements. There is no dielectric filling in the structure (for a vacuum environment), and the distance between the cathode and the grid is controllable. The cathode generates a uniform large current and can be compressed into a high Electron injection of current density can provide electron injection source for electric vacuum devices, effectively expand the application range and other purposes. The manufacturing method of the external grid is as follows: first, a stainless steel metal slice of a certain thickness is processed, and a group of polygonal or circular array meshes of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com