Merging-sorting method based on assembly line process and valve control device using merging-sorting method

A sorting method and pipeline technology, applied in the direction of circuit devices, machine execution devices, concurrent instruction execution, etc., can solve the problems of slow processing speed, large resource occupation, long sorting time, etc., to improve utilization rate, ensure rapidity, shorten The effect of the critical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

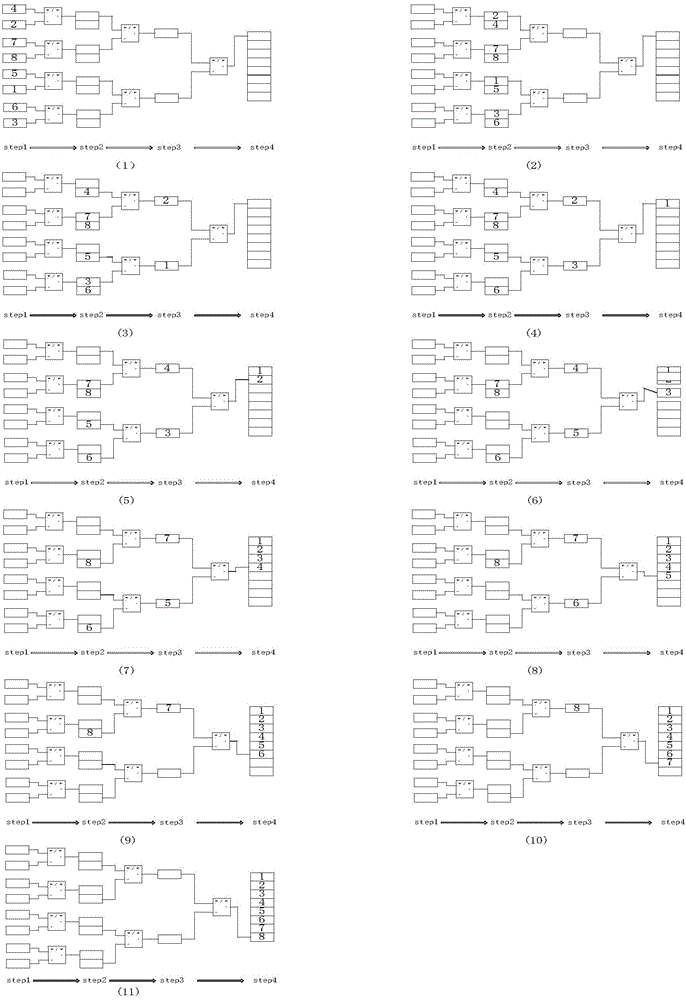

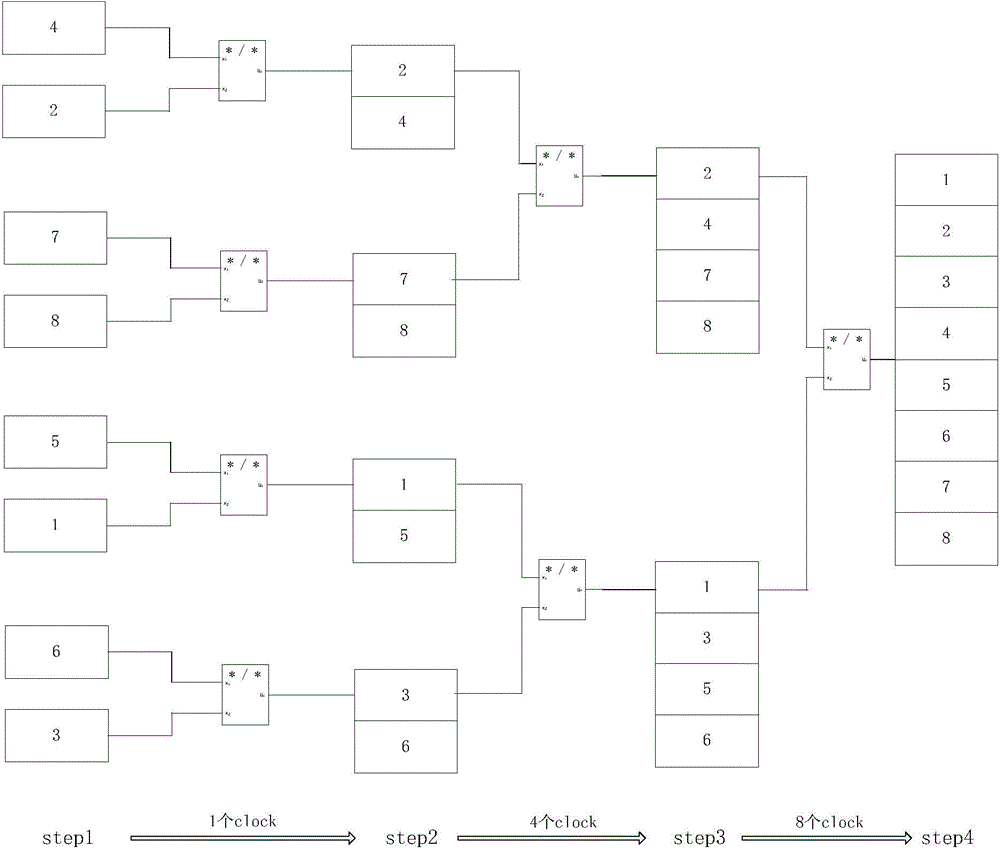

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

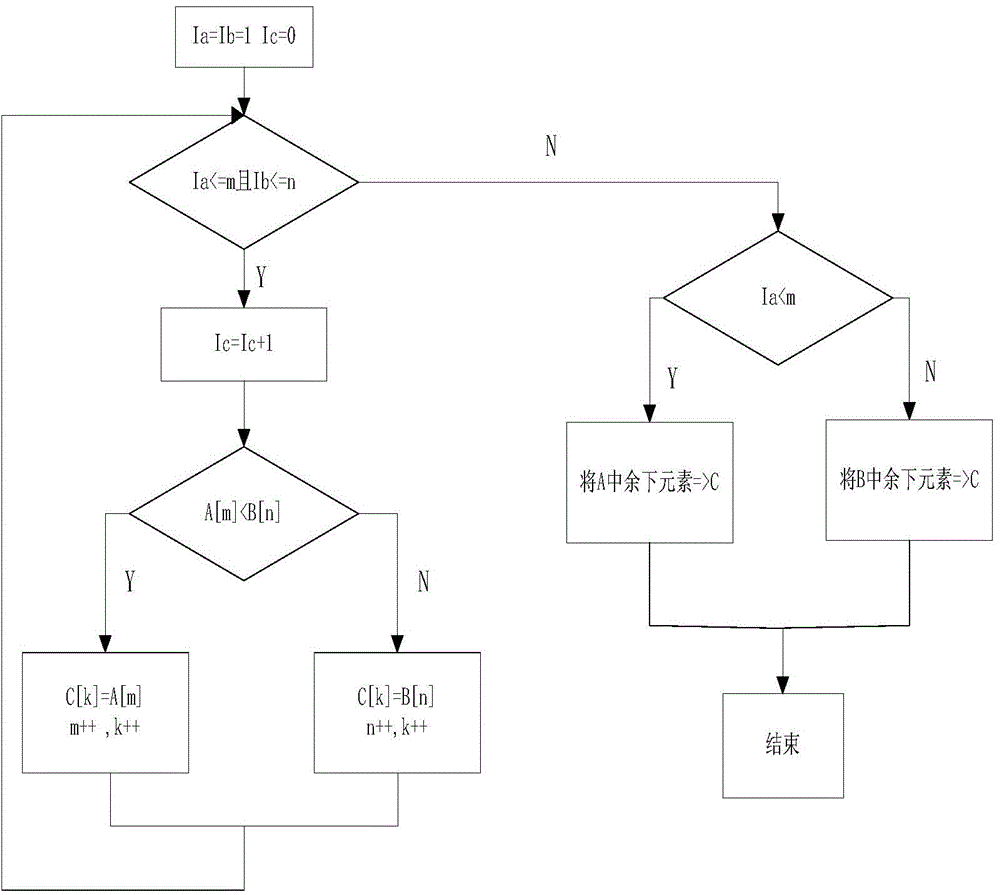

[0029] The present invention is an improvement based on the merge sort algorithm. The merge sort algorithm is a stable sort algorithm and an effective parallel algorithm based on the merge operation. The merge sort is to merge two ordered arrays The operation of forming an ordered array, by comparing the elements in the two arrays, put the smaller elements into the third array, and so on, if one of the arrays reaches the end first, then put the rest of the other array part into a third array, eventually merging the two different arrays into one sorted array. The specific process is as figure 1 As shown, the basic principle is as follows:

[0030] First define three arrays: A=(a1a2...am), B=(b1b2...bn) are two ordered increasing arrays, C=(c1c2...ck) is used to store the sorting results, and the length of the array of C is equal to the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com