Degassing and deslagging compound purification process for molten aluminum smelting

A technology of molten aluminum smelting and compound purification, which is applied in the field of degassing outside the melting furnace, degassing and slag removal of molten aluminum, and the compound purification process of slag removal. Quality impact, difficult to eliminate and other problems, to achieve the effect of improving refining effect and slag separation ability, improving the ability of launder to absorb slag inclusion, and strong ability to dissolve slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A degassing and slag removal composite purification process for molten aluminum smelting, the steps are:

[0031] 1. Degassing and slag removal of molten aluminum in the furnace:

[0032] ⑴ Add high-efficiency active and non-toxic refining agent in the furnace;

[0033] ⑵Using nitrogen as the carrier, the refining agent is blown into the melt, the amount of refining agent added is 0.2% of the mass of the melt, and the ratio of refining agent is Na 2 SiF 6 : 10%, Na 3 AlF 6 : 10%, NaNO 3 : 32%, NaCl: 20%, NaCO 3 : 28%; Nitrogen gas is introduced into the refining rake in the furnace, and the nitrogen gas enters the bottom of the melt through graphite, and the gas flow rate of the nitrogen gas is 4m 3 / h, the refining time is 40min, and the melt refining temperature is 730°C;

[0034] 2. Degassing and slag removal of molten aluminum during pouring outside the furnace:

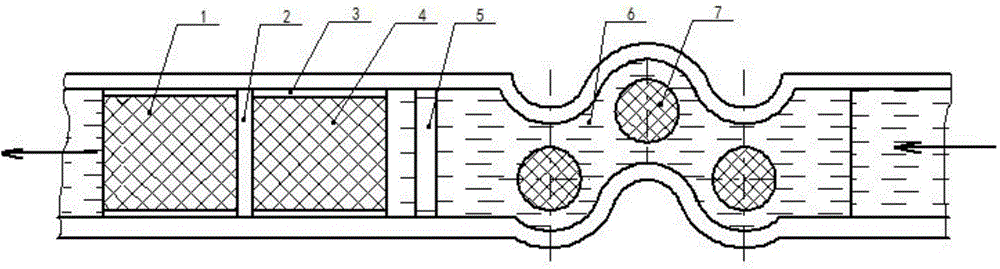

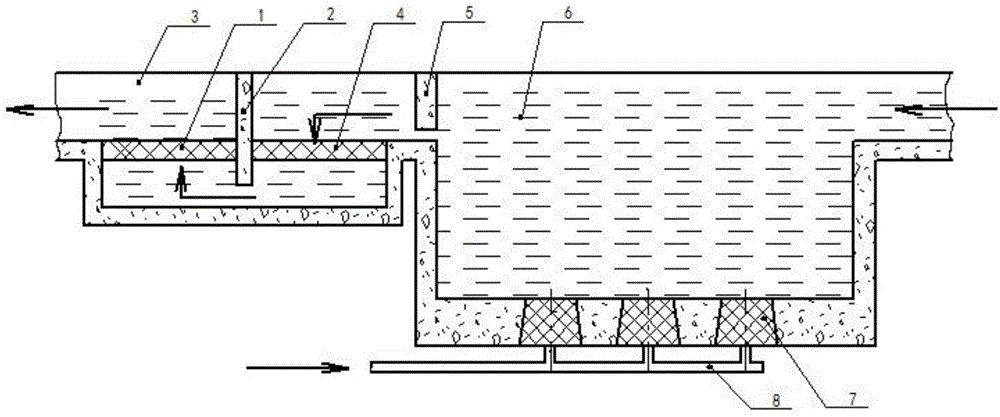

[0035] The purification system of molten aluminum outside the furnace includes a molten aluminu...

Embodiment 2

[0040] A degassing and slag removal composite purification process for molten aluminum smelting, the steps are:

[0041] 1. Degassing and slag removal of molten aluminum in the furnace:

[0042] ⑴ Add high-efficiency active and non-toxic refining agent in the furnace;

[0043] (2) Using nitrogen as a carrier, blow the refining agent into the melt, the amount of refining agent added is 0.3% of the mass of the melt, Na 2 SiF 6 : 12%, Na 3 AlF6 : 13%, NaNO 3 : 30%, NaCl: 15%, NaCO 3 : 30%; Nitrogen is introduced into the refining rake in the furnace, nitrogen enters the bottom of the melt through graphite, and the gas flow rate of nitrogen is 6m 3 / h, the refining time is 30min, and the melt refining temperature is 750°C;

[0044] Two, degassing and slag removal of molten aluminum outside the furnace (the structure of its filter launder and slag removal device is the same as in embodiment 1):

[0045] ⑴ Nitrogen gas is introduced into the bottom of the serpentine molten al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com