A causticizing device and causticizing process in alumina production

A technology of alumina and causticization, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of low alumina recovery rate and high energy consumption, and achieve the effects of improving recovery rate, simplifying causticizing process, and reducing evaporation steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

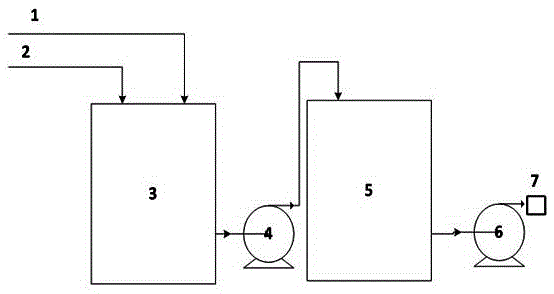

[0014] As shown in the figure, a causticizing device in alumina production is composed of the following structure: causticizing tank 3, the top of causticizing tank 3 communicates with mother liquor evaporation crystallization alkali pipeline 1 and lime milk pipeline 2 for causticizing, The lower part of the causticizing tank 3 is connected to the top of the pressure cooking dissolution dilution tank 5 through a pipeline, and the lower part of the pressure cooking dissolution dilution tank 5 is connected to the dilution pump 6 through a pipeline, and the dilution pump 6 is connected to the red mud separation and washing system 7 through a pipeline. A slurry pump 4 is provided on the pipeline between the causticization tank 3 and the pressure cooking dissolution dilution tank 5 .

[0015] The crystallization alkali evaporated from the mother liquor and the milk of lime for causticization are respectively sent to the causticization tank 3, wherein the CaO in the milk of lime and ...

Embodiment 2

[0017] As shown in the figure, a causticizing device in alumina production is composed of the following structure: causticizing tank 3, the top of causticizing tank 3 communicates with mother liquor evaporation crystallization alkali pipeline 1 and lime milk pipeline 2 for causticizing, The lower part of the causticizing tank 3 is connected to the top of the pressure cooking dissolution dilution tank 5 through a pipeline, and the lower part of the pressure cooking dissolution dilution tank 5 is connected to the dilution pump 6 through a pipeline, and the dilution pump 6 is connected to the red mud separation and washing system 7 through a pipeline. A slurry pump 4 is provided on the pipeline between the causticization tank 3 and the pressure cooking dissolution dilution tank 5 .

[0018] The crystallization alkali evaporated from the mother liquor and the milk of lime for causticization are respectively sent to the causticization tank 3, wherein the CaO in the milk of lime and ...

Embodiment 3

[0020] As shown in the figure, a causticizing device in alumina production is composed of the following structure: causticizing tank 3, the top of causticizing tank 3 communicates with mother liquor evaporation crystallization alkali pipeline 1 and lime milk pipeline 2 for causticizing, The lower part of the causticizing tank 3 is connected to the top of the pressure cooking dissolution dilution tank 5 through a pipeline, and the lower part of the pressure cooking dissolution dilution tank 5 is connected to the dilution pump 6 through a pipeline, and the dilution pump 6 is connected to the red mud separation and washing system 7 through a pipeline. A slurry pump 4 is provided on the pipeline between the causticization tank 3 and the pressure cooking dissolution dilution tank 5 .

[0021] The crystallization alkali evaporated from the mother liquor and the milk of lime for causticization are respectively sent to the causticization tank 3, wherein the CaO in the milk of lime and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com