A control method to solve the versatility of substrate transport trolley

A technology for substrate conveying and control methods, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as reducing equipment automation efficiency, adverse effects of equipment operation, and deviations in conveying accuracy, so as to improve equipment automation efficiency, Avoid equipment overload alarm and hardware damage, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

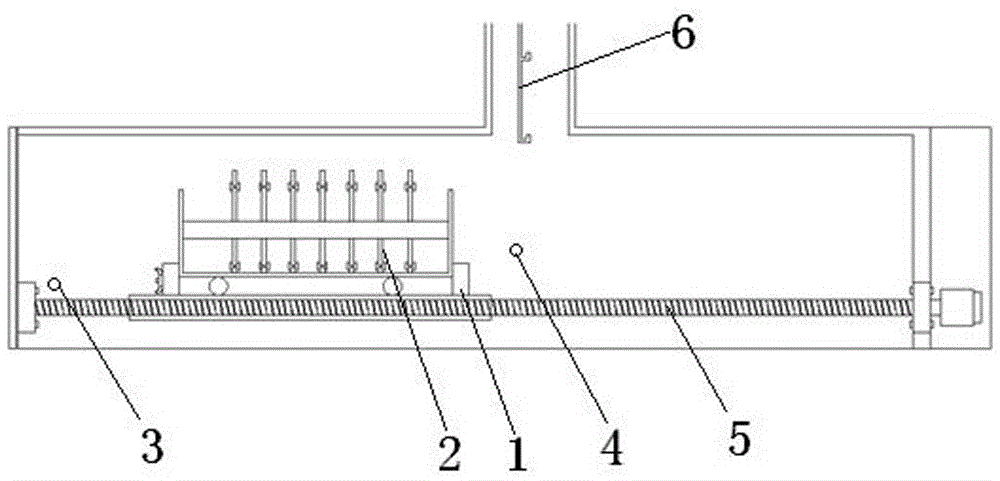

[0016] Embodiment: In this embodiment, the control system of the substrate transport trolley detects the front and rear positions of the substrate transport trolley and compensates the substrate transport position accordingly. like figure 1 As shown, the substrate transport trolley 1 can run on the guide rail 5 through a driving device to transport a plurality of substrates 2 carried by it to the grabbing position of the robot arm 6 . As an optical fiber sensor, the optical fiber sensor 4 is installed in front of the robot arm 6 , that is, the substrate transport trolley 1 first passes the fiber optic sensor 4 and then reaches the grasping position of the robot arm 6 .

[0017] The control method of the present embodiment comprises the following steps:

[0018] (1) Calculate the distance between the substrate transfer cart 1 as the reference from the origin 3 of the substrate transfer cart to the optical fiber sensor 4, record it in the form of coordinates, and record and sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com