Packing machine for inner rings and outer rings of coils

A technology of inner and outer rings and coils, which is applied in the direction of rotating and wrapping items, can solve the problems of high equipment cost and operating costs, high safety risks for multiple liftings, and high labor intensity for workers. It is not easy to wear, has a small range of activities, and The effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

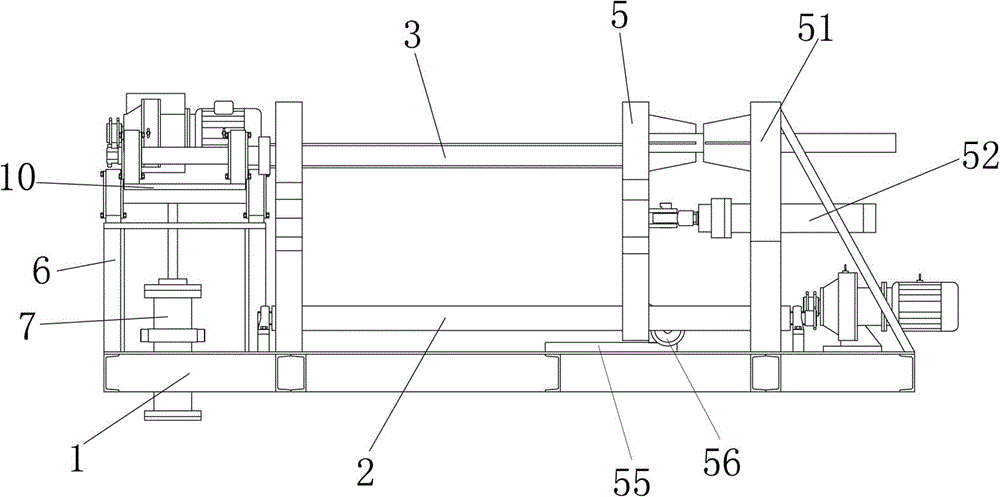

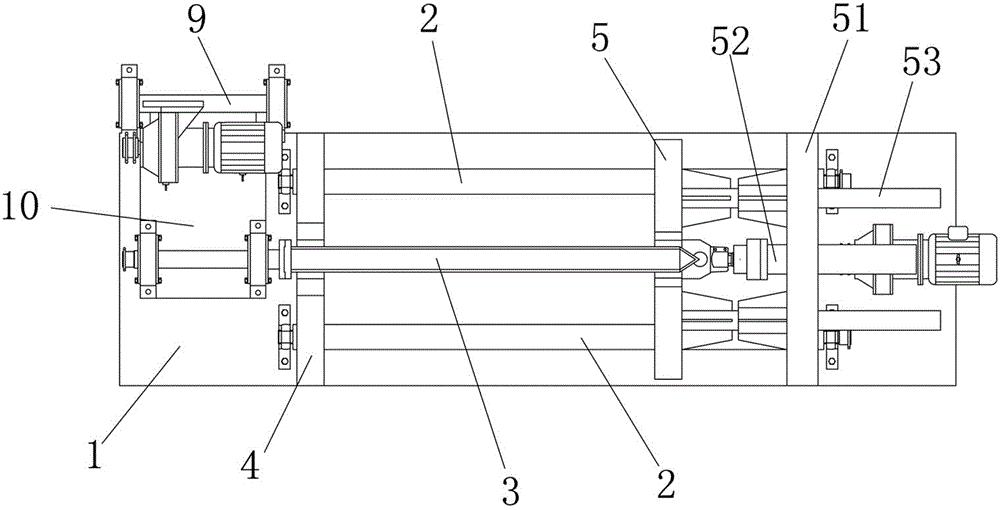

[0036] A coil inner and outer ring packing machine, which is characterized in that it comprises a base 1, an outer ring rolling device, an inner ring rolling device and a pressing device for pressing the coil, the pressing device includes a vertical and parallel Two pressure plates for compressing the coils are erected on the base. The outer ring rolling device includes an outer ring rotating shaft 2 for supporting and arranging the outer ring of the coil. The inner rolling device includes The inner ring rotating shaft 3 that determines the size of the inner ring.

[0037] The baler also includes a coil feeding and turning device for rotating the inner ring rotating shaft so that the coil is placed on the inner ring rotating shaft and sent to the packaging position, and the inner ring rotating shaft is set on the coil feeding and turning device .

[0038] The pressing plate includes a fixed backing plate 4 and a movable pressing plate 5 that can adjustably move back and forth alon...

Embodiment 2

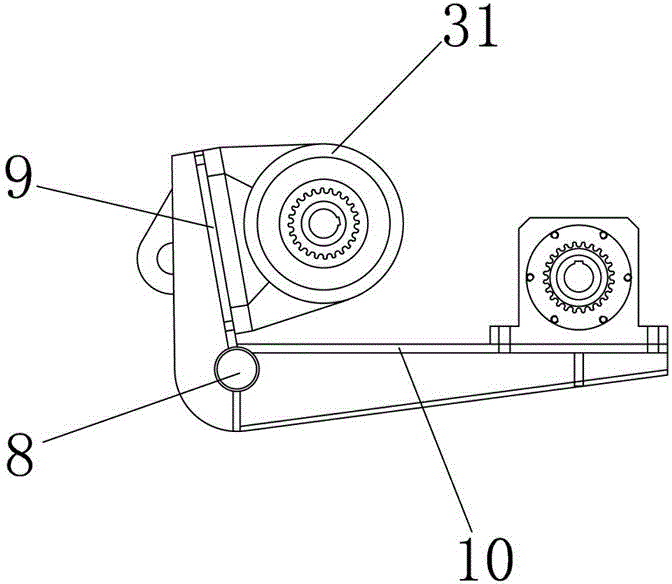

[0046] The difference from the above-mentioned embodiment is that the angle between the active cantilever plate 9 and the driven cantilever plate 10 is 110 degrees, and the outer ring rotation axis is two ends respectively passing through the fixed backing plate and the driving guide plate and arranged in parallel. , The movable pressure plate is provided with an open port 57 for passing through the outer ring rotating shaft.

Embodiment 3

[0048] The difference from the above embodiment is that the angle between the active cantilever plate 9 and the driven cantilever plate 10 is 105 degrees.

[0049] When in use, first press the movable platen to move away from the fixed backing plate, and at the same time, the driven cantilever plate is driven to rotate by turning the oil cylinder, so as to drive the inner ring rotating shaft to rotate out of the fixed ring opening upwards to the side of the base, and turn it out completely. The coil is sleeved on the inner ring rotating shaft, the turning cylinder is reopened, the inner ring rotating shaft is re-entered into the fixed ring opening, and the inner ring rotating shaft is positioned in the fixed ring opening according to the predetermined specifications of the packing coil After positioning, move the movable pressing plate to the fixed backing plate, and lightly press the coil to ensure that the coil is closed to a certain range, but still in a loose state. Start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com