Connection method of reaction sintered silicon carbide ceramic green body

A technology for sintering silicon carbide and ceramic green bodies, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of inability to reduce the thermal mismatch between the connecting material and the base material to be connected, large thermal stress of the joint, and low bonding strength. The effect of eliminating thermal mismatch, high bond strength, ensuring surface accuracy and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Wherein, ethanol-based initiator is the ethanol solution containing polyvinyl butyral and APS, and the concentration of polyvinyl butyral is 60-140g / L, and the concentration of APS is 1.5-8g / 100ml, and ethanol is analytically pure, for making The dispersion is better, and the particle size of APS is generally within 10 μm. The present invention provides a method for preparing the above-mentioned ethanol-based initiator, but is not limited thereto: first dissolve polyvinyl butyral in ethanol, mix evenly, and obtain an ethanol-based solution, and the concentration of polyvinyl butyral in the ethanol-based solution is 60 -140g / L, then grind the APS until the particle size is less than or equal to 10μm, and then disperse the ground APS particles in the ethanol-based solution to obtain the ethanol-based suspension of APS, which is the ethanol-based initiator. In the silicon carbide slurry, the primary free radicals formed by the homolysis of the initiator activate the polyme...

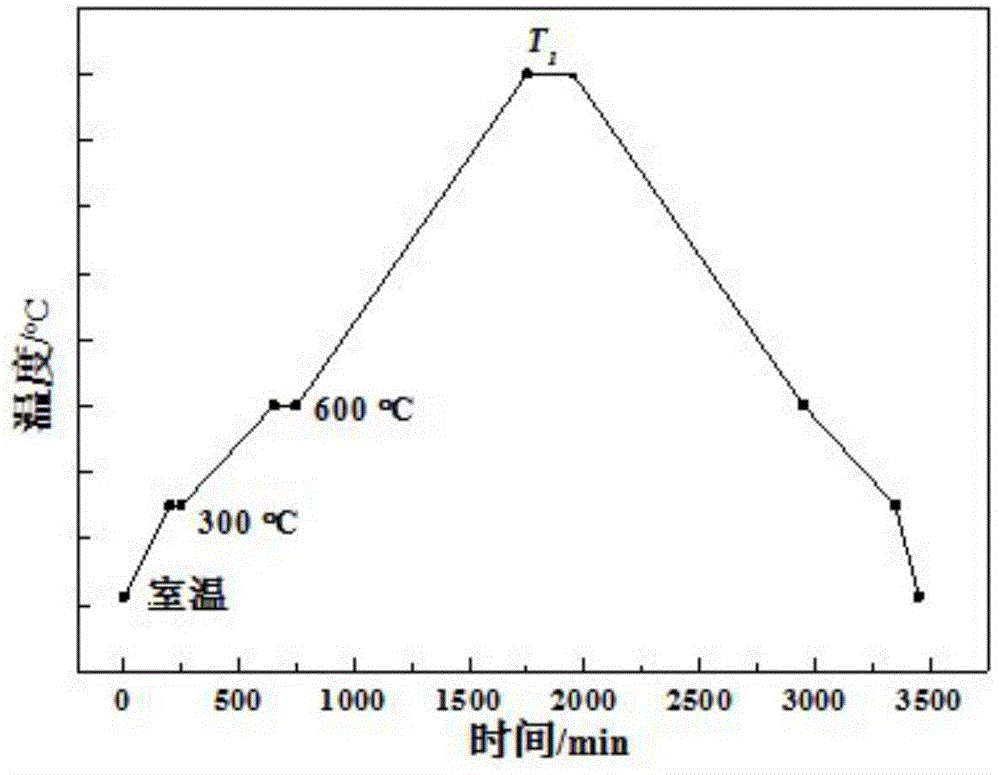

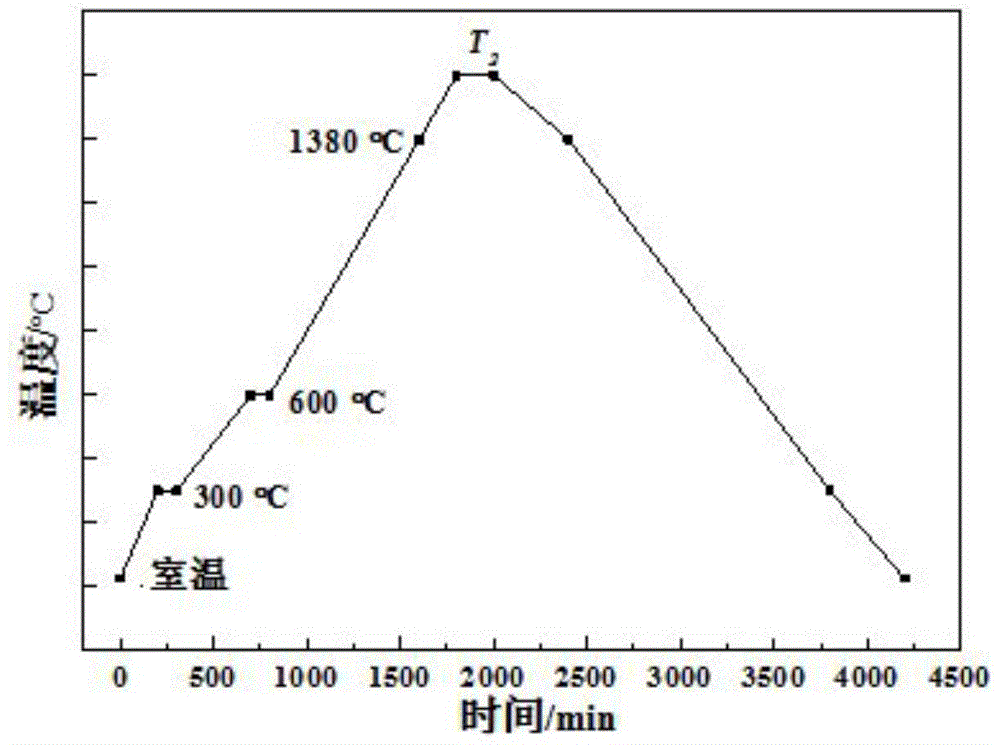

Embodiment 1

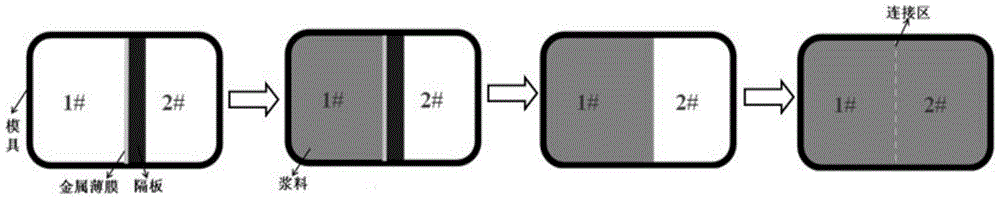

[0057] Connection method of reaction sintered silicon carbide ceramic green body:

[0058] Step 1, mold is divided into 1# and 2# two zones with detachable dividing plate, brush one deck ethanol-based initiator (the concentration of polyvinyl butyral is 60g / L at the inner surface of the mold of 1# zone , the concentration of APS is 3.5g / 100ml), paste tin foil on the surface of the partition in 1# area;

[0059] Step 2: Inject silicon carbide slurry (solid content: 60vol.%) into the 1# area, and solidify at 18°C for 1.5 hours to obtain silicon carbide green body;

[0060] Step 3: Perform moisturizing treatment on the silicon carbide biscuit in the 1# area, and the moisturizing time is 5 hours;

[0061] Step 4. After removing the separator and tin foil, paint a water-based initiator on the connecting surface of the silicon carbide green body. The concentration of APS in the water-based initiator is 8g / 100ml;

[0062] Step 5. After the water-based initiator is applied for 0.5...

Embodiment 2

[0067] Connection method of reaction sintered silicon carbide ceramic green body:

[0068] Step 1, mold is divided into two zones of 1# and 2# with detachable dividing plate, brushes one deck ethanol base initiator (the concentration of polyvinyl butyral is 80g / L at the inner surface of the mold of 1# zone , the concentration of APS is 8g / 100ml), paste aluminum foil on the surface of the partition in 1# area;

[0069] Step 2: Inject silicon carbide slurry (solid content: 62.5vol.%) into the 1# area, and solidify at 25°C for 2 hours to obtain a silicon carbide green body;

[0070] Step 3: Perform moisturizing treatment on the silicon carbide biscuit in the 1# area, and the moisturizing time is 10 hours;

[0071] Step 4. After removing the separator and tin foil, paint a water-based initiator on the connecting surface of the silicon carbide green body. The concentration of APS in the water-based initiator is 8g / 100ml;

[0072] Step 5: After painting with the water-based initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com