A Printed Circuit Board Structure for Partial Elimination of Thermal Mismatch in Thickness Direction

A printed circuit board, thickness direction technology, applied in the direction of printed circuits, circuit substrate materials, printed circuit components connected to non-printed electrical components, etc., can solve problems such as inability to find, avoid damage to solder joints, Eliminate the effects of thermal mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

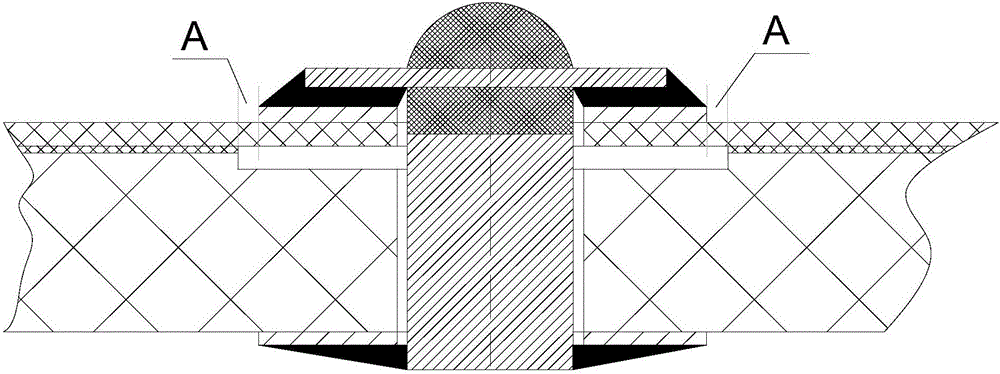

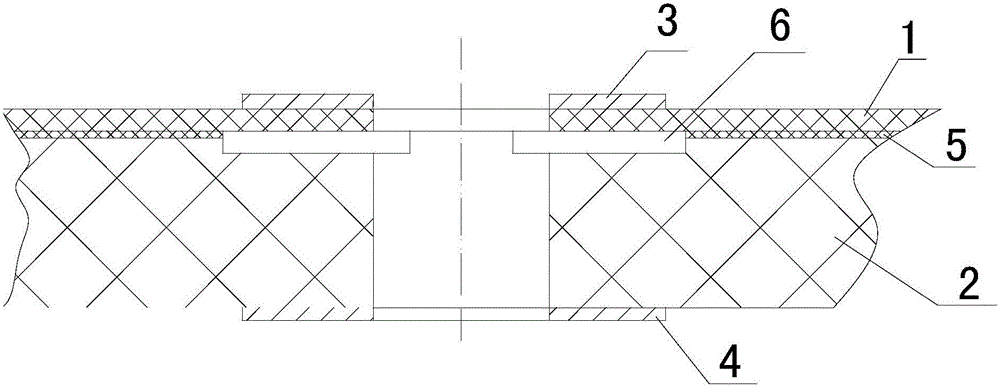

[0028] The flexible board 1 is designed to be made of polyimide material, with conductive patterns and two top-layer pads 3 laid on the upper surface. The top-layer pads 3 are rectangular in shape and 4×1.5mm in size. The rigid board 2 is an epoxy glass cloth board with conductive patterns and bottom pads 4 on its lower surface, and the adhesive 5 is made of prepreg; the upper surface of the rigid board 2 is designed with two grooves 6, the shape of the grooves is rectangular, and the size It is 4.5×2mm, and the groove depth is 0.2mm. The lower surface of the flexible board 1 and the upper surface of the rigid board 2 are bonded together by an adhesive 5 to form a complete printed circuit board. During the bonding process, ensure that each of the flexible board 1 and the rigid board 2 The corresponding position accuracy of the conductive pattern, the error is less than ±0.1mm.

[0029] The bonding material is a prepreg material commonly used in the PCB industry. The shape of ...

Embodiment 2

[0034] The flexible board 1 is designed to be made of polyimide material, with a conductive pattern and two top-layer pads 3 arranged on the upper surface. The top-layer pad 3 is square in shape and 2×2mm in size. The rigid board 2 is an epoxy glass cloth board with conductive patterns and bottom pads 4 on its lower surface, and the adhesive 5 is a prepreg; the upper surface of the rigid board 2 is designed with two grooves 6, the shape of the grooves is square, and the size It is 3×3mm, and the groove depth is 0.3mm. The lower surface of the flexible board 1 and the upper surface of the rigid board 2 are bonded together by an adhesive 5 to form a complete printed circuit board. During the bonding process, ensure that each of the flexible board 1 and the rigid board 2 The corresponding position accuracy of the conductive pattern, the error is less than ±0.1mm.

[0035] The bonding material is a prepreg material commonly used in the PCB industry. The shape of the bonding glue is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com