Gadolinium block material and preparation method thereof

A technology of bulk materials and gadolinium blocks, which is applied in the field of gadolinium block materials and its preparation, can solve the problems of difficult preparation and difficult preparation of nanoparticles, and achieve the effects of easy-to-obtain raw materials, simple preparation process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation method of Gd block material 1:

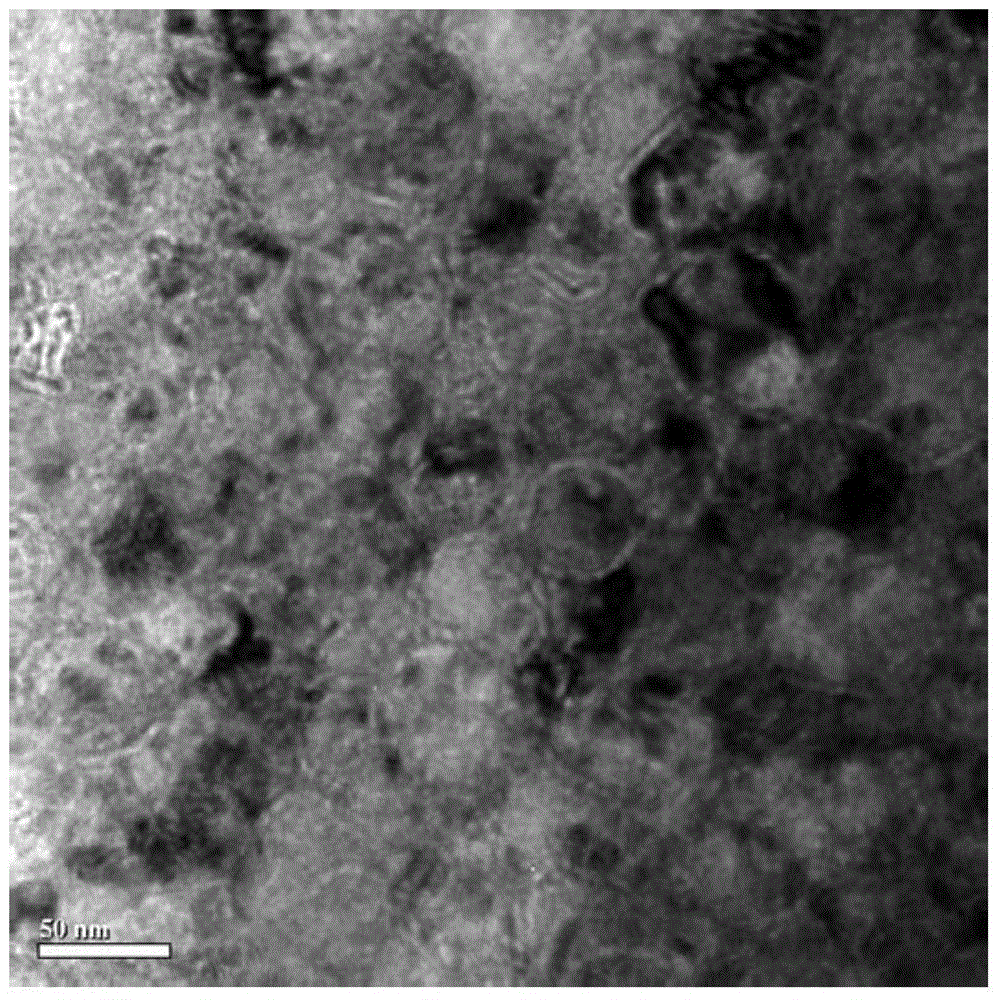

[0031] (1) Put 4 grams of metal gadolinium powder raw materials and 120 grams of stainless steel metal grinding balls (ball-to-material ratio is 30:1) into a 250ml stainless steel grinding jar together, and fill the argon (Ar) of 1 bar for protection; The ball milling tank with the raw material sample installed, that is, the above grinding tank is placed on a ball mill for ball milling, the ball milling conditions: the ball milling speed is 400rpm, and the ball milling time is 40 hours;

[0032] (2) In the pretreatment chamber (oxygen concentration is 0.4ppm) protected by high-purity argon gas (purity reaches more than 99.99%), put the ground gadolinium powder into the WC cemented carbide mold, and then pre-press it under 2Mpa pressure ;

[0033] (3) Put the mold containing gadolinium powder into spark plasma sintering (SPS for short) equipment (model SPS-5.40-IV / ET) to sinter it into metallic gadolinium bulk material. The ...

Embodiment 2

[0043] Preparation method of Gd block material 2:

[0044] (1) 4 grams of metal gadolinium powder raw materials and 200 grams of stainless steel metal grinding balls (ball-to-material ratio is 50:1) are put into a 250ml stainless steel grinding jar together, and the argon (Ar) that fills into 3bar is protected; Then put The ball milling tank with the raw material sample installed, that is, the above grinding tank is placed on a ball mill for ball milling, the ball milling conditions: the ball milling speed is 500rpm, and the ball milling time is 60 hours;

[0045] (2) In the pretreatment chamber (oxygen concentration is 0.3ppm) protected by high-purity argon gas (purity reaches more than 99.99%), put the ground gadolinium powder into the WC cemented carbide mold, and then pre-press it under 2Mpa pressure ;

[0046] (3) Put the mold containing gadolinium powder into spark plasma sintering (SPS for short) equipment (model SPS-5.40-IV / ET) to sinter it into metallic gadolinium bu...

Embodiment 3

[0052] Preparation method of Gd block material 3:

[0053] (1) 4 grams of metal gadolinium powder raw materials and 240 grams of stainless steel metal grinding balls (ball-to-material ratio is 60:1) are put into a 250ml stainless steel grinding jar together, and the argon (Ar) that fills into 3bar is protected; Then put The ball milling tank with the raw material sample installed, that is, the above grinding tank is placed on the ball mill for ball milling, the ball milling conditions: the ball milling speed is 300rpm, and the ball milling time is 20 hours;

[0054] (2) In a pretreatment chamber (oxygen concentration of 0.3ppm) protected by high-purity argon (purity above 99.99%), put the ground gadolinium powder into a WC cemented carbide mold, and then pre-press it under a pressure of 2Mpa ;

[0055] (3) Put the mold containing gadolinium powder into spark plasma sintering (SPS for short) equipment (model SPS-5.40-IV / ET) to sinter it into metal gadolinium bulk material. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com