Temperature controllable electronic condensation rotary evaporator

A rotary evaporator, controllable technology, applied in the direction of distillation in rotating containers, refrigerators, sustainable buildings, etc., can solve the problem that water-cooled condensers are difficult to reach the condensation temperature, the recovery rate of low-boiling volatile solvents is low, and the distillate Can not be accurately controlled and other problems, to achieve the effect of simple structure, easy popularization and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

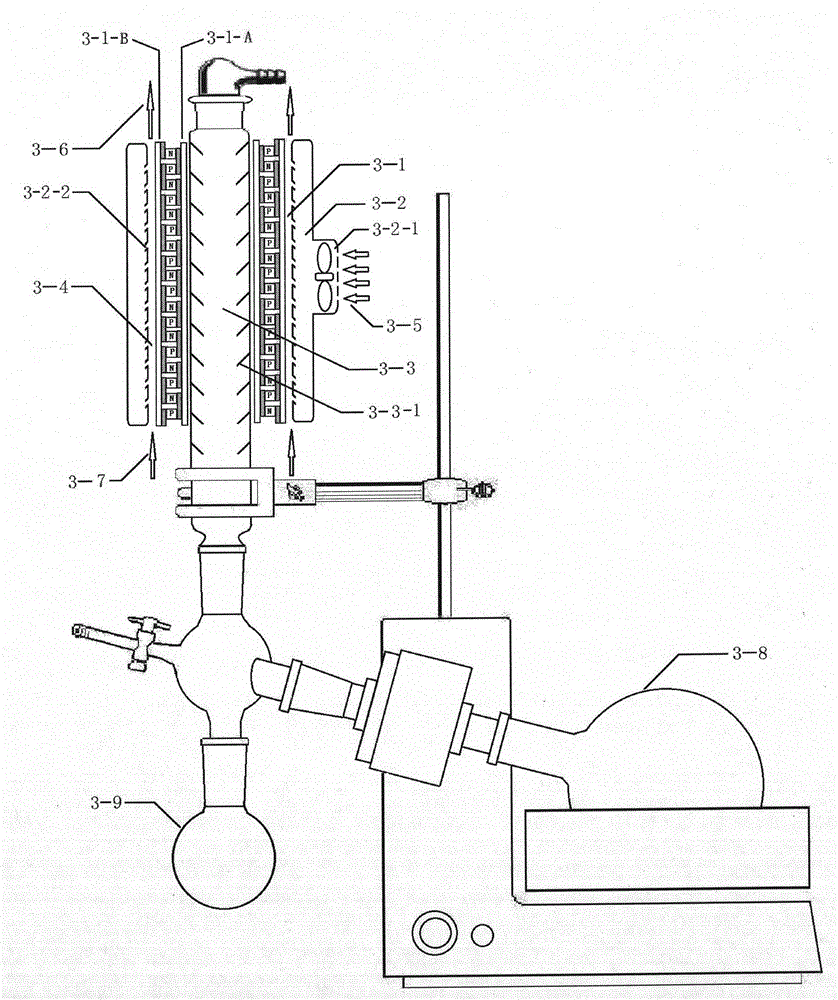

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

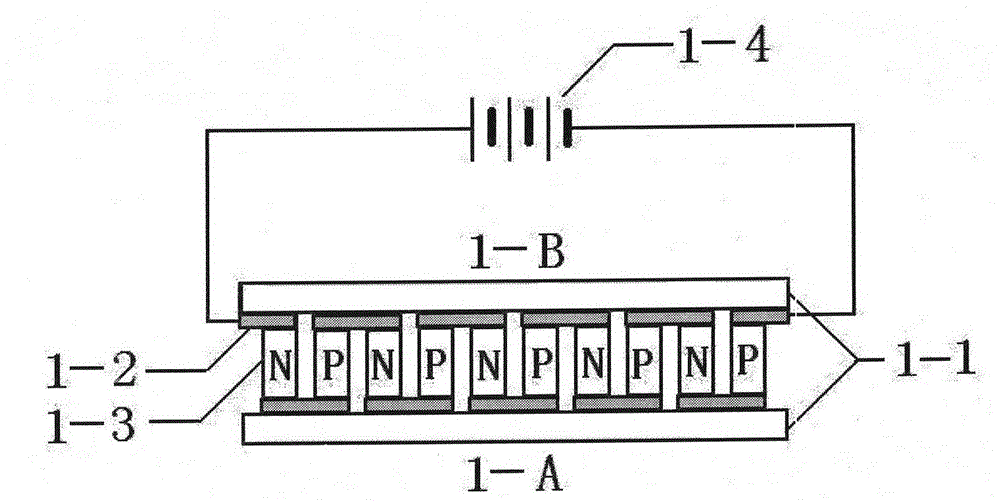

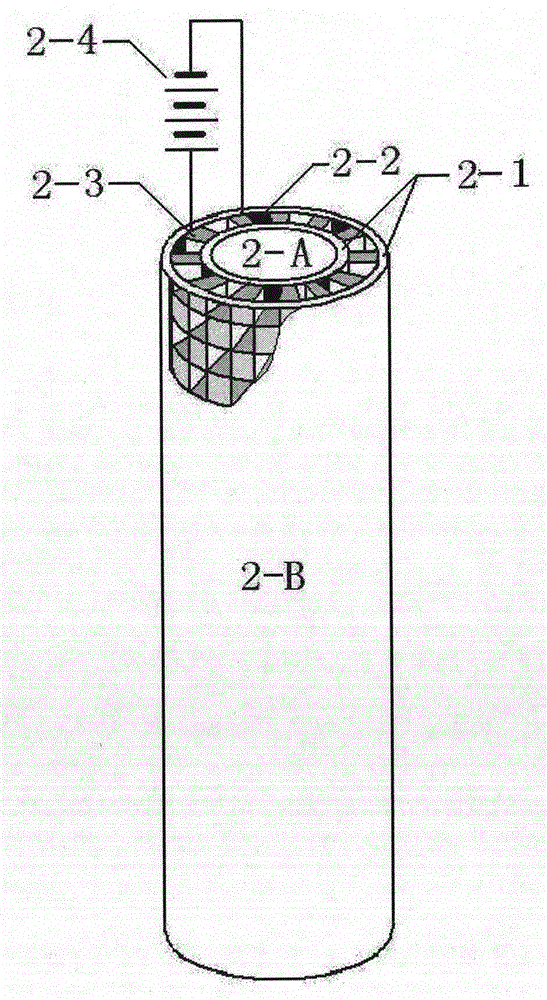

[0027] The structure and working principle of electronic refrigeration components are as follows: figure 1 , figure 2 As shown, 1-1 and 2-1 are insulating ceramics, 1-2 and 2-2 are metal conductors, 1-3 and 2-3 are N-type and P-type semiconductors, 1-4 and 2-4 are DC power supplies . After the DC power supply is connected to the electronic refrigeration element, the energy transfer will be generated immediately, and the current will flow from the N-type element to the joint of the P-type element to absorb heat, and the 1-A and 2-A surfaces will become cold junctions, and the temperature will drop; from the P-type element to the N The joints of the type components release heat, and the 1-B and 2-B surfaces become hot ends and the temperature rises. Usually, the temperature difference between the cold and hot ends of electronic refrigeration c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com