Print-ink stacked body

A printing ink and laminate technology, applied in the direction of ink, layered products, synthetic resin layered products, etc., can solve the problems of low pigment dispersion, insufficient design, low gloss of ink coating film surface, etc., to achieve gloss Excellent, residual solvent reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

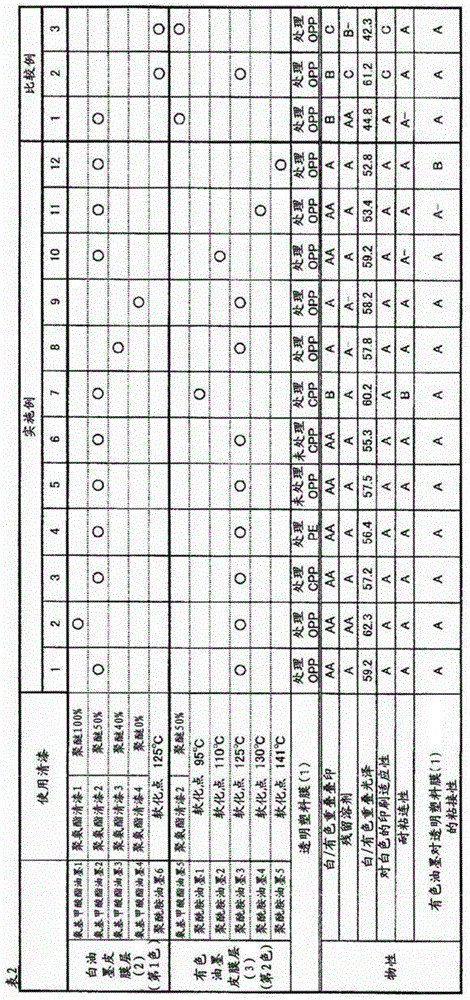

[0089] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples. In addition, although the evaluation of the gravure printing method was performed in the Example of this application, since the same printed matter can also be produced by flexographic printing, it is absolutely not intended to limit the printing method. Parts and % in the present invention represent parts by mass and % by mass unless otherwise noted.

[0090]

Synthetic example 1

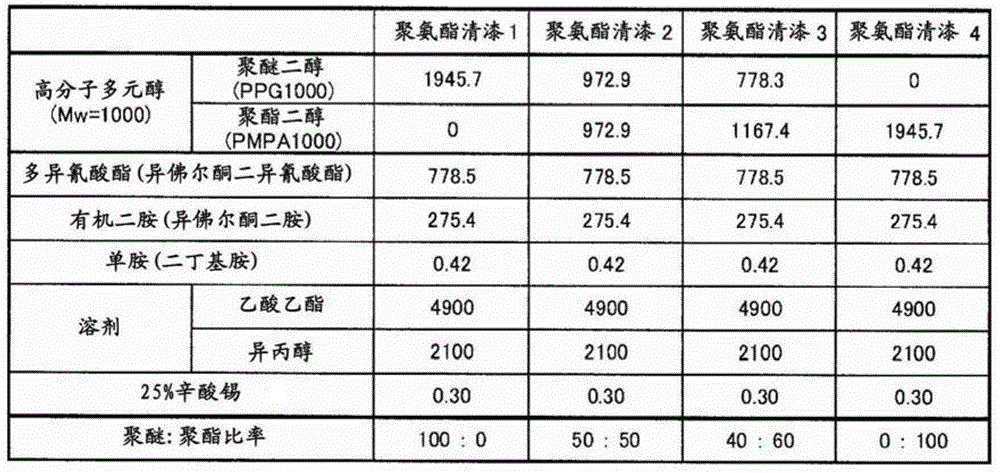

[0092] 1945.7 parts of polypropylene glycol (PPG1000, manufactured by NOF Corporation) with a number average molecular weight (hereinafter referred to as Mn) of 1000, and 778.5 parts of isophorone diisocyanate were added to a four-necked flask equipped with a stirrer, a thermometer, a reflux cooler, and a nitrogen introduction tube. 0.30 parts of stannous 2-ethylhexanoate and 900 parts of ethyl acetate, reacted at 85°C for 3 hours under a nitrogen stream, added 1000 parts of ethyl acetate and cooled to obtain a solvent solution of terminal isocyanate prepolymer 4624.5 share. Next, to a mixture obtained by mixing 275.4 parts of isophorone diamine, 0.42 parts of di-n-butylamine, 3000 parts of ethyl acetate, and 2100 parts of isopropanol, slowly added the obtained terminal isocyanate prepolymer 4624.5 parts at room temperature. parts, followed by reaction at 50° C. for 1 hour to obtain a polyurethane varnish 1 with a solid content of 30% and a weight average molecular weight of 3...

Synthetic example 2

[0094] Into a four-necked flask equipped with a stirrer, a thermometer, a reflux cooler, and a nitrogen inlet tube, 972.9 Mn1000 polyester diol (PMPA1000, manufactured by Kuraray) obtained from adipic acid and 3-methyl-1,5-pentanediol was added. 972.9 parts of Mn1000 polypropylene glycol (PPG1000, manufactured by NOF Corporation), 778.5 parts of isophorone diisocyanate, 0.30 parts of stannous 2-ethylhexanoate, and 900 parts of ethyl acetate, at 85°C under a nitrogen stream After reacting for 3 hours, 1000 parts of ethyl acetate was added and cooled to obtain 4624.5 parts of a solvent solution of a terminal isocyanate prepolymer. Next, to a mixture obtained by mixing 275.4 parts of isophoronediamine, 0.42 parts of di-n-butylamine, 3000 parts of ethyl acetate, and 2100 parts of isopropyl alcohol, the obtained terminal isocyanate prepolymer was slowly added at room temperature 4624.5 parts, followed by reaction at 50° C. for 1 hour to obtain a polyurethane varnish 2 with a solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com