Output fiber form distribution PDF modeling method for high consistency refining system

A fiber morphology, high-consistency refining technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of fiber morphology modeling and control difficulties, inability to distribute probability density function modeling and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

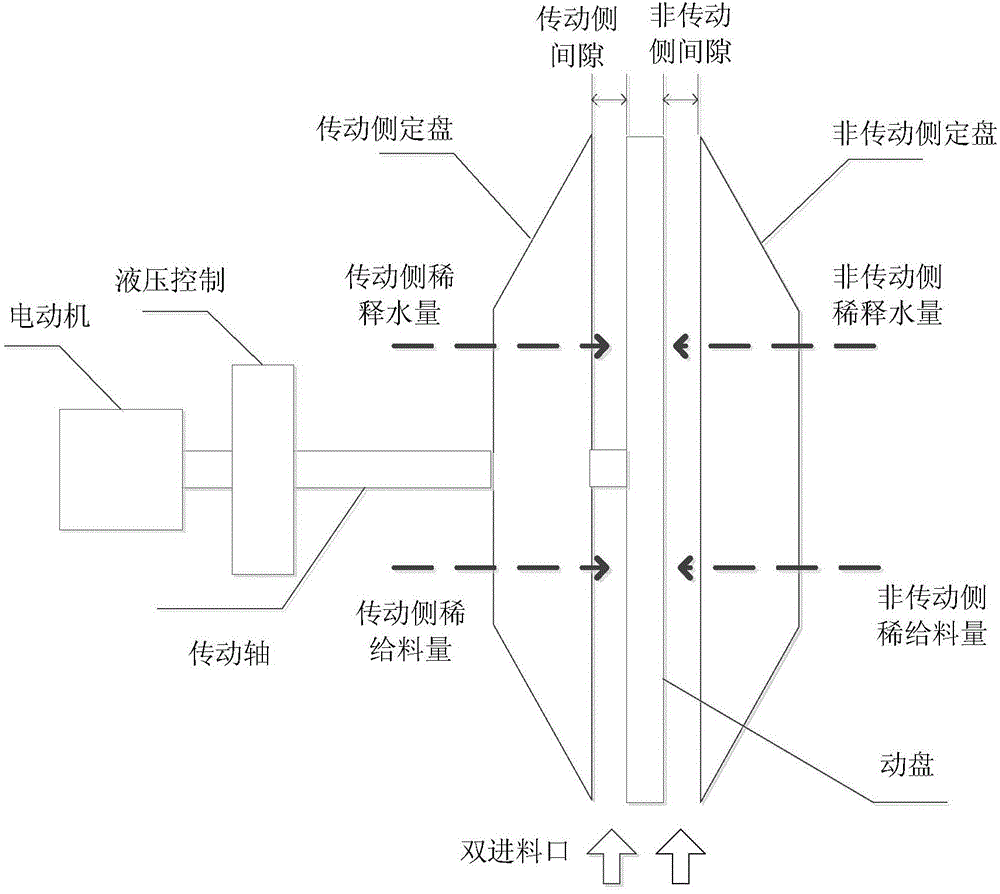

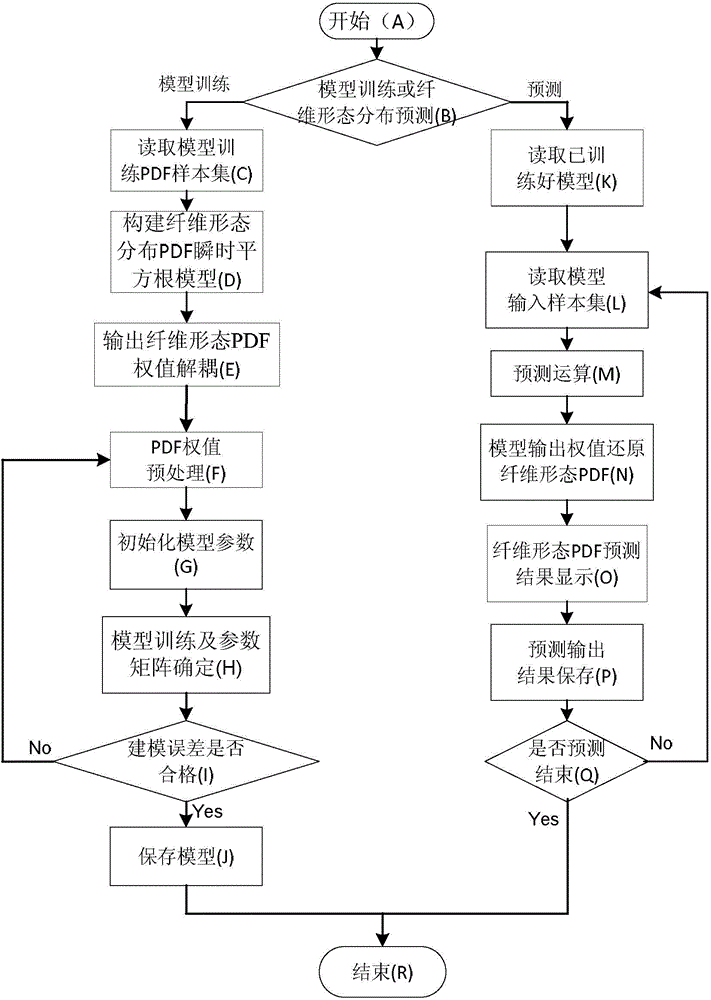

[0092] As shown in the figure, the implementation method of the present invention includes (1) auxiliary variable selection and model input variable determination, (2) training and predictive use of the fiber morphology distribution PDF model.

[0093] (1) Selection of auxiliary variables and determination of model input variables

[0094] Auxiliary variables are chosen as:

[0095] Dilution water u 1 (t)(l / min);

[0096] High concentration grinding disc speed u 2 (t)(rpm);

[0097] High-concentration disc clearance u 3 (t)(mm);

[0098] The variables listed above are the input variables of the model, and the output variables that need to be measured on-line in real time are the PDF (probability density function) γ(y, u(t)).

[0099] (2) Model training and use

[0100] (A) start: variable initialization;

[0101] (B) Model training or fiber shape distribution prediction: If you choose model training, go to (C), read the output fiber shape distribution PDF sample set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com