Optoacoustic type laser breakdown detection device

A technology of laser breakdown and detection device, which is applied in the field of spectral measurement, can solve the problems of indistinguishable spectral lines, decreased detection sensitivity, low detection sensitivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

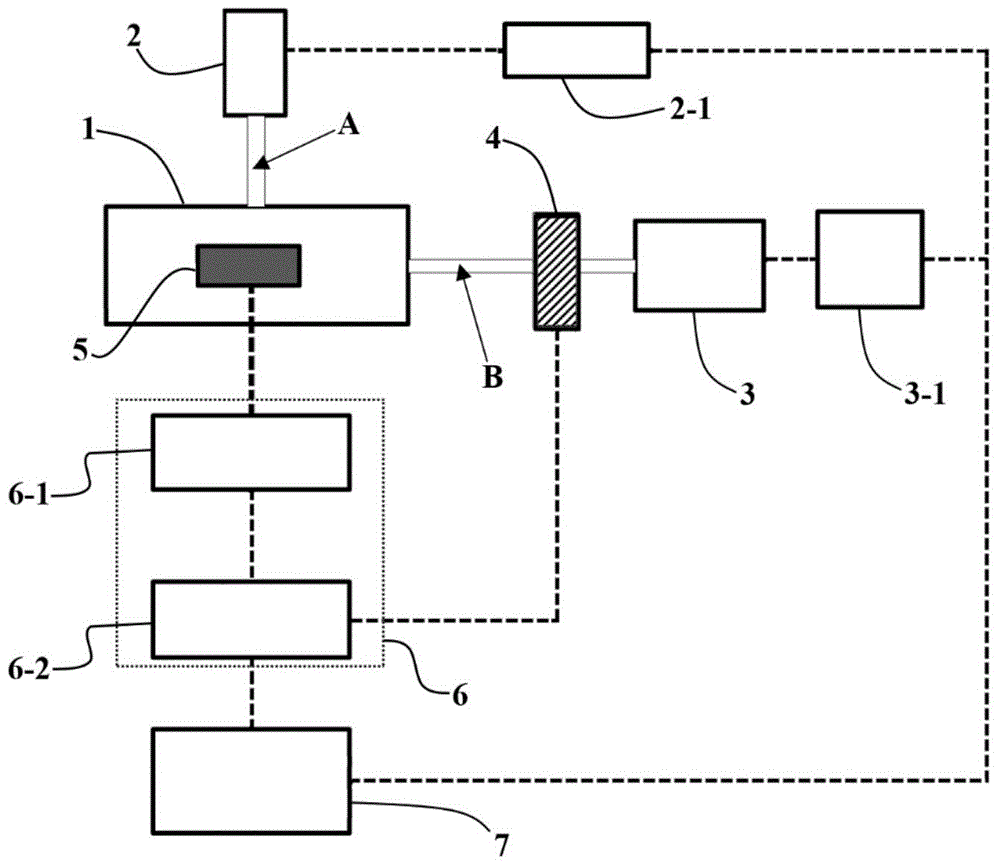

[0026] figure 2 Shown is the overall structure of the detection device. The signal detected by the micro-sound detector 5 is amplified by the preamplifier 6-1. The function of the chopper 4 is to provide a modulation signal to the detection light source 3, and periodically modulate the detection light source 3. output light frequency. The signals of the preamplifier 6-1 and the chopper 4 are simultaneously input into the lock-in amplifier 6-2, and the signal of the lock-in amplifier 6-2 is output to the host computer 7 for data collection, and the host computer 7 is also connected with the light source controller 1 simultaneously. It is connected with the light source controller 2, and the switching time of the two light sources can be controlled through the light source controller.

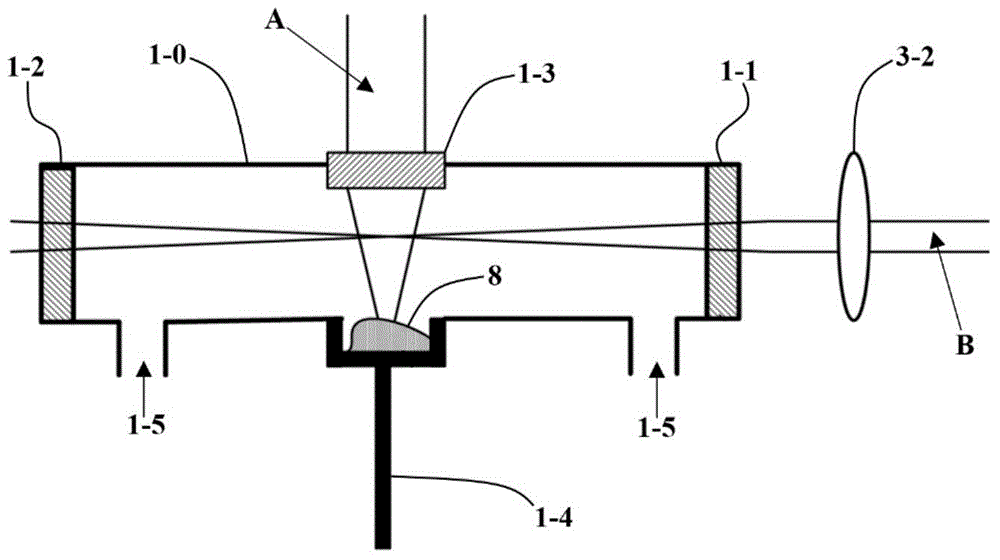

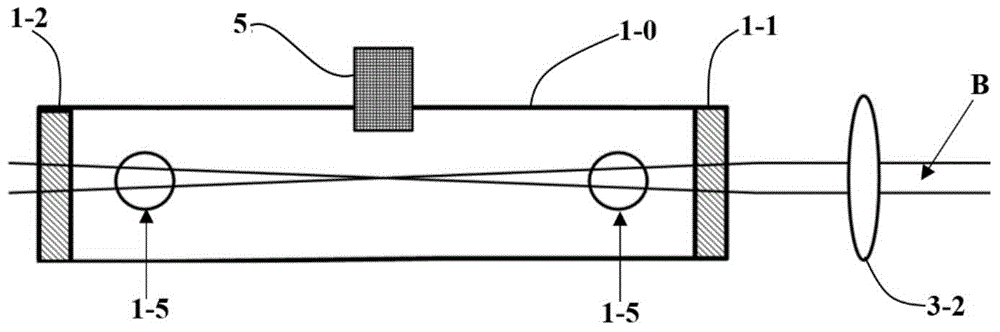

[0027] Figure 1a and 1b Shown is the specific structure of the photoacoustic absorption cavity 1, wherein opposite incident windows 1-1 and exit windows 1-2 are embedded at both ends of the p...

Embodiment 2

[0040]The basic structure of the device is the same as in Example 1. When the content of Fe needs to be detected, because the absorption line of Fe is 248.7nm, the detection light source 3 can be changed to a tunable alexandrite laser (Cr 3+ :BeAl 2 o 4 ), the third harmonic band of the alexandrite laser is 240-270nm, and the laser (third harmonic) emitted by the alexandrite laser is absorbed by the Fe molecules in the nanoparticle cloud to produce a photoacoustic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com