Inkjet printing conductive ink capable of sintering at room temperature and its application

A conductive ink and inkjet printing technology, which is applied in the application field of inkjet printing conductive ink and inkjet printing conductive ink, can solve the problems of unsatisfactory sintering effect, consume a lot of energy, and damage the substrate, and achieve good printing. The effect of fluency, rapid and uniform dissolution, and strong printing continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

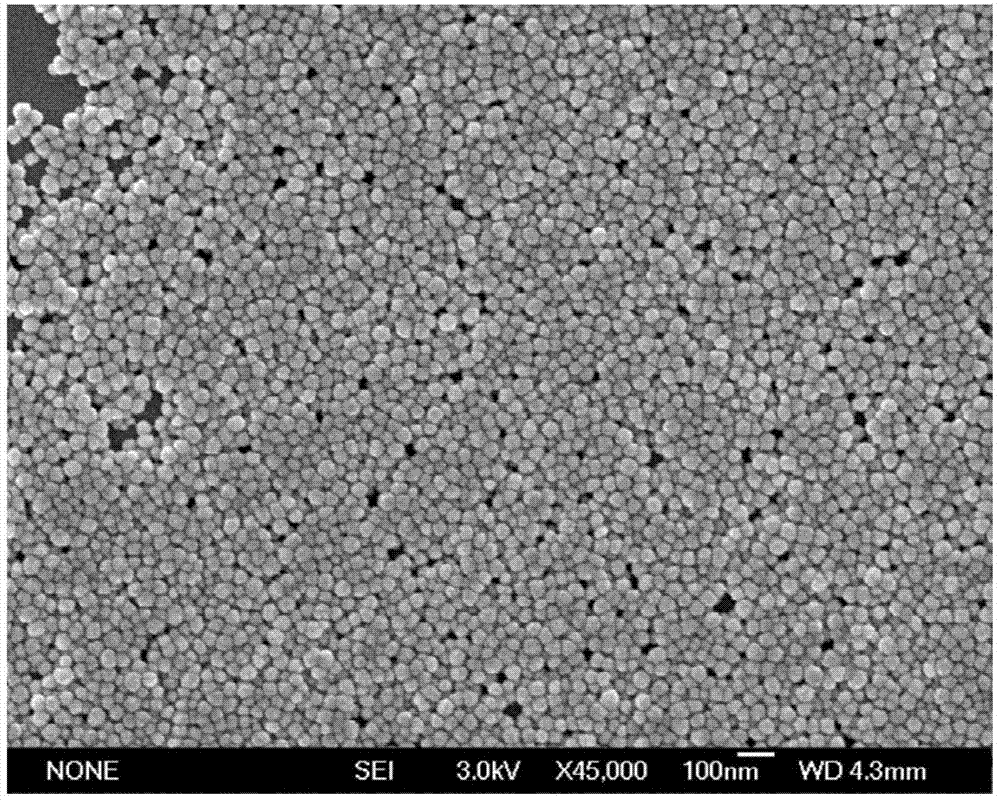

[0044] Using the method provided in the literature Zhiliang Zhang, Xingye Zhang, Yanlin Song.The synthesis of silver nanoparticles and its application in the ink-jet printingelectrocircuits.Chemistry, 2011, 74(10), 874-880, the surface is coated with as a stabilizer The silver nanoparticles of polyvinylpyrrolidone, its polyvinylpyrrolidone accounts for 0.5% of the mass fraction of the silver nanoparticles coated with polyvinylpyrrolidone as a stabilizer on the surface, and the average particle size of the silver nanoparticles coated with polyvinylpyrrolidone on the surface is 50nm. Its scanning electron microscope picture is shown in figure 1 .

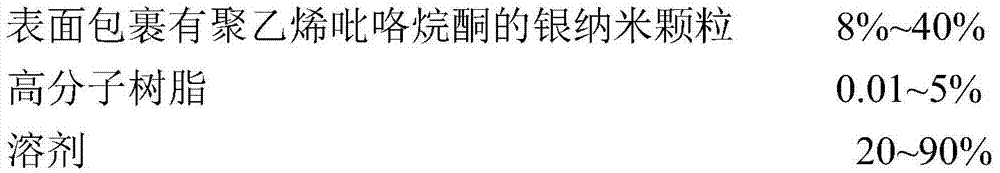

[0045] The inkjet printing conductive ink that can be sintered at room temperature is prepared by using the above-mentioned silver nanoparticles coated with polyvinylpyrrolidone on the surface. The composition and the mass percentage of each component of the inkjet printing conductive ink that can be sintered at room temperature are ...

Embodiment 2

[0067] Utilize the method for embodiment 1, prepare the silver nanoparticle that the surface is coated with polyvinylpyrrolidone as stabilizer, its polyvinylpyrrolidone accounts for 0.5% of the mass fraction of the silver nanoparticle that surface is wrapped with polyvinylpyrrolidone as stabilizer, the surface The average particle diameter of the silver nanoparticles wrapped with polyvinylpyrrolidone is 40nm.

[0068] Utilize above-mentioned silver nanoparticle that the surface is coated with polyvinylpyrrolidone to prepare the ink-jet printing conductive ink that can sinter at room temperature, the composition and the mass percentage of each component of the ink-jet printing conductive ink that can be sintered at room temperature are as follows:

[0069] Silver nanoparticles coated with polyvinylpyrrolidone: 18%

[0070] Ethylene glycol anisole: 80.15%

[0071] Polyacrylic acid: 0.25%

[0072] Sodium pyrophosphate: 1.5%

[0073] Sorbic acid: 0.02%

[0074] BYK410: 0.02% ...

Embodiment 3

[0088] Utilize the method for embodiment 1, prepare the silver nanoparticle that the surface is coated with polyvinylpyrrolidone as stabilizer, its polyvinylpyrrolidone accounts for 0.5% of the mass fraction of the silver nanoparticle that surface is coated with polyvinylpyrrolidone as stabilizer, the surface The average particle size of the silver nanoparticles wrapped with polyvinylpyrrolidone is 30nm.

[0089] Utilize above-mentioned silver nanoparticle that the surface is coated with polyvinylpyrrolidone to prepare the inkjet printing conductive ink that can sinter at room temperature, the composition and the mass percentage of each component of the inkjet printing conductive ink that can be sintered at room temperature are as follows:

[0090] Silver nanoparticles coated with polyvinylpyrrolidone: 30%

[0091] Ethylene glycol anisole: 68.15%

[0092] Polyacrylic acid: 0.25%

[0093] Sodium pyrophosphate: 1.5%

[0094] Sorbic acid: 0.02%

[0095] BYK410: 0.02%

[0096...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com