Two-dimensional fiber/boron nitride nanotube multistage reinforcement and preparation method thereof

A technology of boron nitride nanotubes and reinforcements, applied in the field of composite material preparation, to achieve the effects of easy availability, low raw material cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

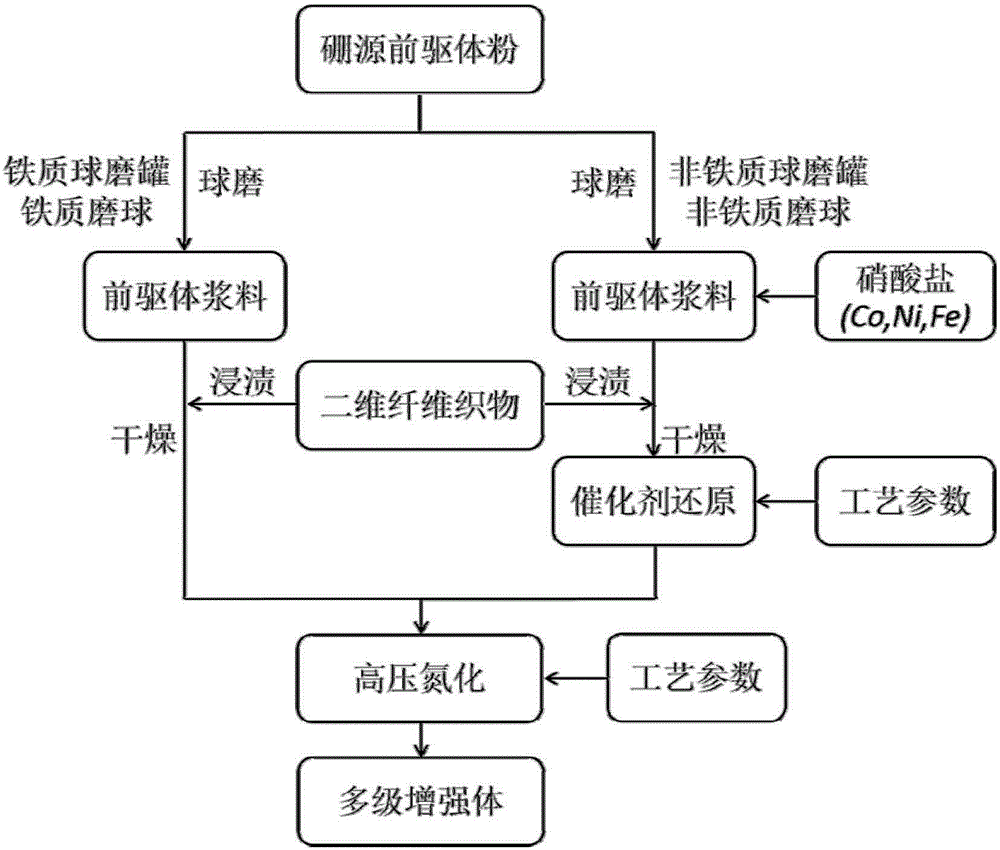

[0026] The preparation method of multi-stage reinforcing body of the present invention, concrete steps are as follows:

[0027] 1) Iron ball mill jar and iron ball mill:

[0028] ①According to the mass ratio of ball to material 1-150:1, put the boron source precursor powder and iron balls in the iron ball mill tank, add non-aqueous solvent as the ball mill medium, or pass in NH3 for ball mill without adding liquid medium Protection, ball milling at 150-440rpm for 24-150h;

[0029] ② Add the ball-milled precursor to the same non-aqueous solvent as the ball-milling medium (if no liquid ball-milling medium is added during ball-milling, just add a non-aqueous solvent directly) to make a slurry, cut the two-dimensional fiber fabric, Put it into the above-mentioned slurry for immersion, and perform ultrasonication for 1 hour during the immersion process to ensure good suspension of the slurry. The impregnated two-dimensional fiber fabric was put into a drying oven and dried at 85 ...

Embodiment 1

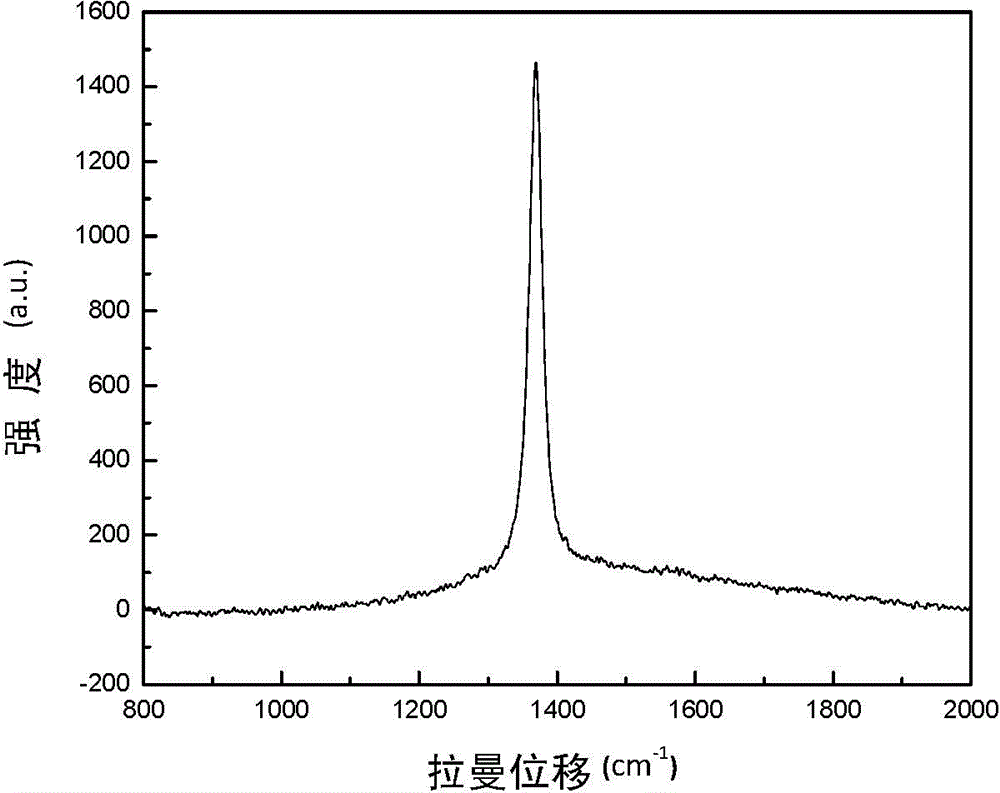

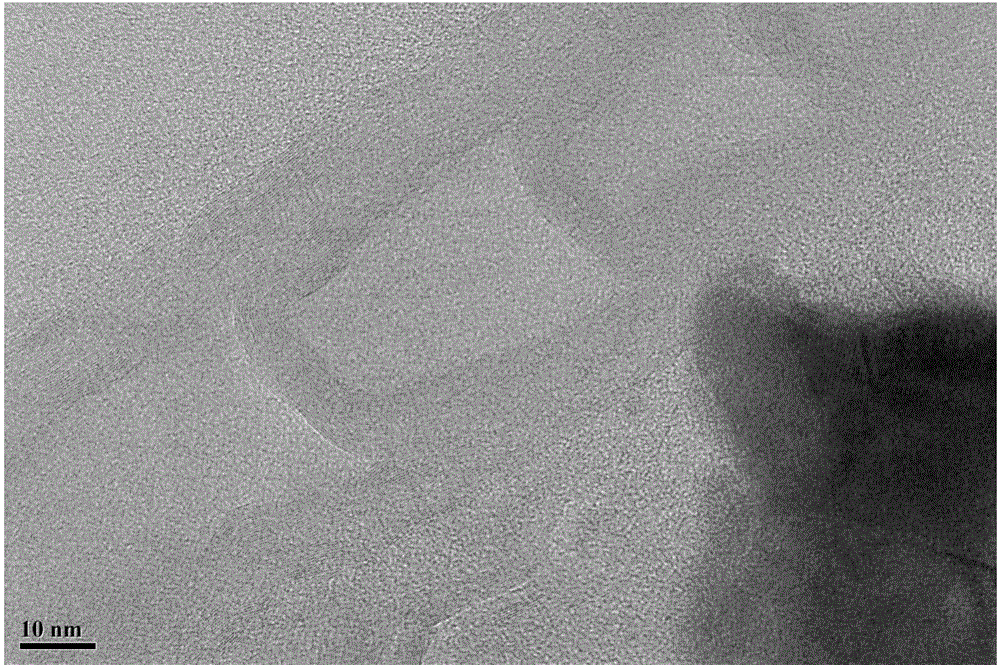

[0063] Put boron powder and stainless steel balls in a stainless steel ball mill tank according to the mass ratio of the ball to material 20:1, add ethanol as the ball mill medium, and mill at a speed of 400rpm for 80h. Add appropriate amount of ethanol to the ball-milled precursor to make a slurry, cut a small piece of two-dimensional carbon fiber fabric, put it into the above slurry for impregnation, and perform ultrasonication for 1 hour during the impregnation process to ensure good suspension of the slurry. Then the impregnated two-dimensional carbon fiber fabric was put into a drying oven and dried at 85 °C for 1 h. Finally, the impregnated and dried two-dimensional carbon fiber fabric was put into a high-pressure nitriding furnace, and high-purity nitrogen was introduced until the pressure in the high-pressure furnace reached 2MPa, and the temperature of the high-pressure furnace was raised to the growth temperature of boron nitride nanotubes at 1400°C, and kept warm. 2...

Embodiment 2

[0065] When the precursor powder is ball milled, no liquid ball milling medium is added, and only NH3 is passed in for protection. Others are the same as in Example 1. As a result, a two-dimensional fiber / boron nitride nanotube multi-level reinforcement is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com