Glass fiber

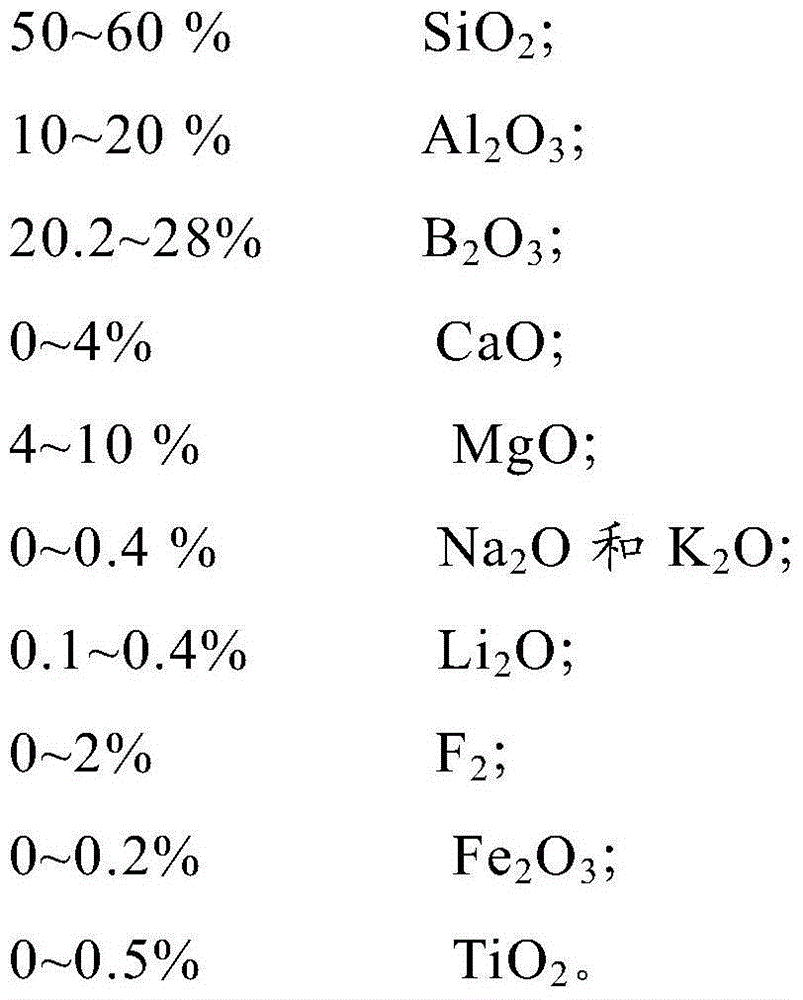

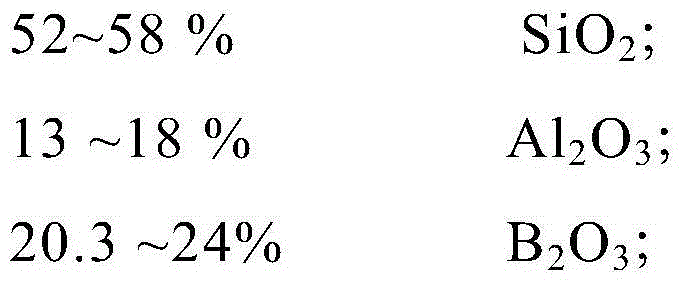

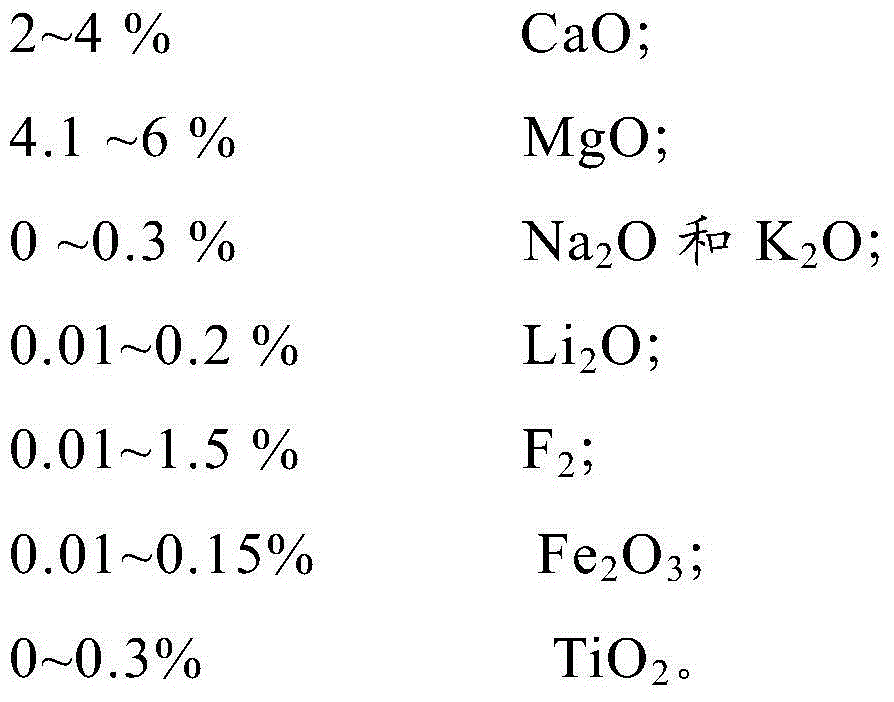

A glass fiber, mass percentage technology, applied in the field of inorganic non-metallic materials, can solve the problems of low dielectric constant, difficult production, poor melting, etc., to reduce the dielectric constant and dielectric loss, molding temperature and upper limit of crystallization Low temperature and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the glass fiber is not particularly limited in the present invention, and it can be prepared according to the tank kiln method well known to those skilled in the art.

[0045] According to the actual formula of the glass, calculate the required raw material addition ratio; according to the ratio, the various raw materials are quantitatively transported to the mixing bin, fully mixed evenly, and qualified batch materials are obtained; the batch materials are transported to the kiln head bin of the pool kiln, and The feeder is delivered to the tank kiln at a uniform speed; the batch material is heated, melted, clarified and homogenized in the tank kiln to form qualified molten glass; the molten glass is cooled to the molding temperature through the working channel, and then flows out through the platinum drain plate to form Glass filament: under the high-speed traction of the wire drawing machine, the glass filament is quickly drawn into a glass f...

Embodiment 1~6

[0048] The glass fiber is prepared by the pool kiln method.

[0049] Quantitatively transport various raw materials to the mixing bin according to the proportion, fully mix and evenly, and obtain qualified batch materials;

[0050] Convey the batch material to the kiln head silo of the tank kiln, and deliver it to the tank kiln at a uniform speed by the feeder;

[0051] The batch materials are heated, melted, clarified and homogenized in the tank kiln at a temperature not exceeding 1330°C to form qualified molten glass; the molten glass is cooled to the forming temperature through the working channel, and then flows out through the platinum drain plate to form glass filaments;

[0052]The glass filaments are quickly drawn into glass fibers with a set diameter under the high-speed traction of the wire drawing machine. After being sprayed and cooled, coated with a sizing agent and bundled, they are wound into a silk cake by the wire drawing machine; in the programmed automatic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com