Bisphenol A-type cyanate ester resin prepolymer and preparation method thereof

A type of cyanate ester and prepolymer technology, applied in the field of bisphenol A type cyanate ester resin prepolymer and its preparation, can solve problems such as non-toxicity, environmental hazard and/or toxicity, and achieve simple operation process, Effects of short prepolymerization time, low dielectric constant and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

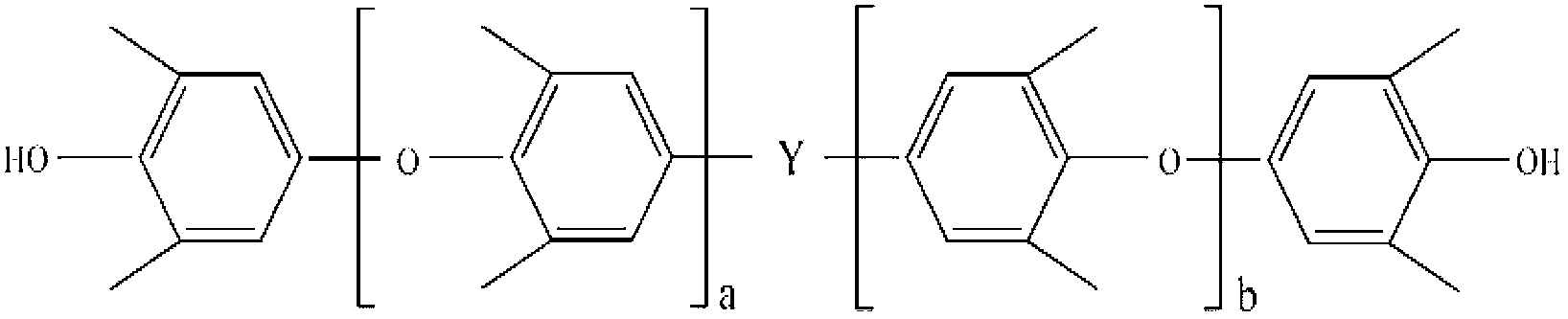

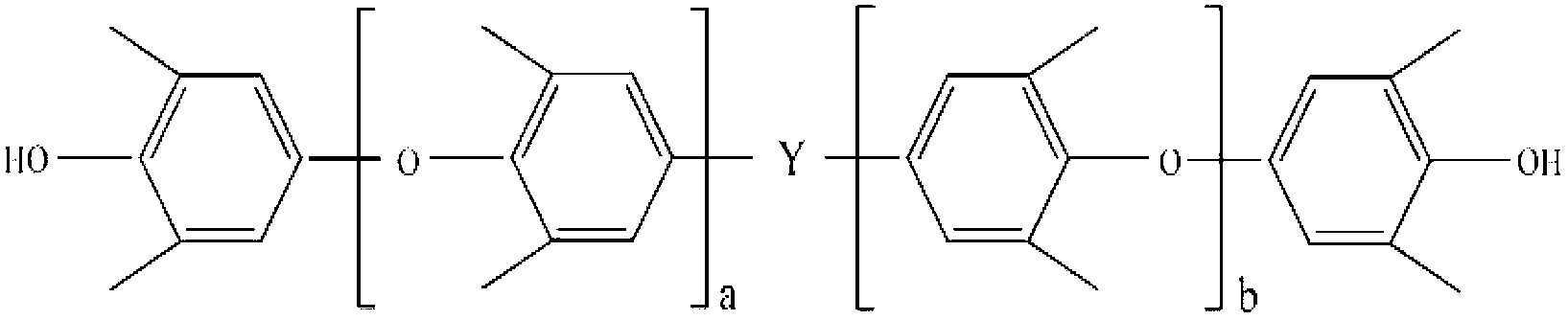

[0026] A kind of preparation method of bisphenol A type cyanate resin prepolymer, take bisphenol A type cyanate ester monomer as main material, polyphenylene ether is auxiliary material, preparation process is as follows:

[0027] Take 100g of bisphenol A type cyanate monomer and heat and melt at 140°C; then add 5g of polyphenylene ether with a number-average molecular weight of 1500g / mol, and continue the heat preservation reaction for 10 hours while keeping stirring. When the system's refractive index reaches 1.584 , Cool down to end the reaction; when the cooling temperature reaches about 75°C, add 45g butanone to the polymer, stir evenly and cool to room temperature to obtain a bisphenol A cyanate resin prepolymer with a solid content of 70%.

Embodiment 2

[0029] A kind of preparation method of bisphenol A type cyanate resin prepolymer, take bisphenol A type cyanate ester monomer as main material, polyphenylene ether is auxiliary material, preparation process is as follows:

[0030] Take 100g of bisphenol A type cyanate ester monomer and heat and melt at 150°C; add 1g of polyphenylene ether with a number average molecular weight of 1500g / mol, and continue to keep warm for 8 hours while keeping stirring. When the system's refractive index reaches 1.585, Cool down to end the reaction; when the cooling temperature reaches about 75°C, add 43.3g butanone to the polymer, stir evenly and cool to room temperature to obtain a bisphenol A cyanate resin prepolymer with a solid content of 70%.

Embodiment 3

[0032] A kind of preparation method of bisphenol A type cyanate resin prepolymer, take bisphenol A type cyanate ester monomer as main material, polyphenylene ether is auxiliary material, preparation process is as follows:

[0033] Take 100g of bisphenol A type cyanate monomer and heat and melt at 160°C; add 0.5g of polyphenylene ether with a number average molecular weight of 1000g / mol, and continue to keep warm for 6 hours while keeping stirring. When the system's refractive index reaches 1.587 , the temperature was lowered to end the reaction; when the cooling temperature reached about 75°C, 43.1 g of butanone was added to the polymer, stirred evenly and then cooled to room temperature to obtain a bisphenol A cyanate resin prepolymer with a solid content of 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Refractive coefficient | aaaaa | aaaaa |

| Refractive coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com