Preparation method and application method of membrane pollution inhibitor for membrane bioreactor

A technology of membrane bioreactor and application method, which is applied in the field of preparation of membrane fouling inhibitors for membrane bioreactors, can solve the problems of complex enzyme purification process, high cost, poor stability, etc., and achieve the solution of inhibitor loss and low cost , the effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

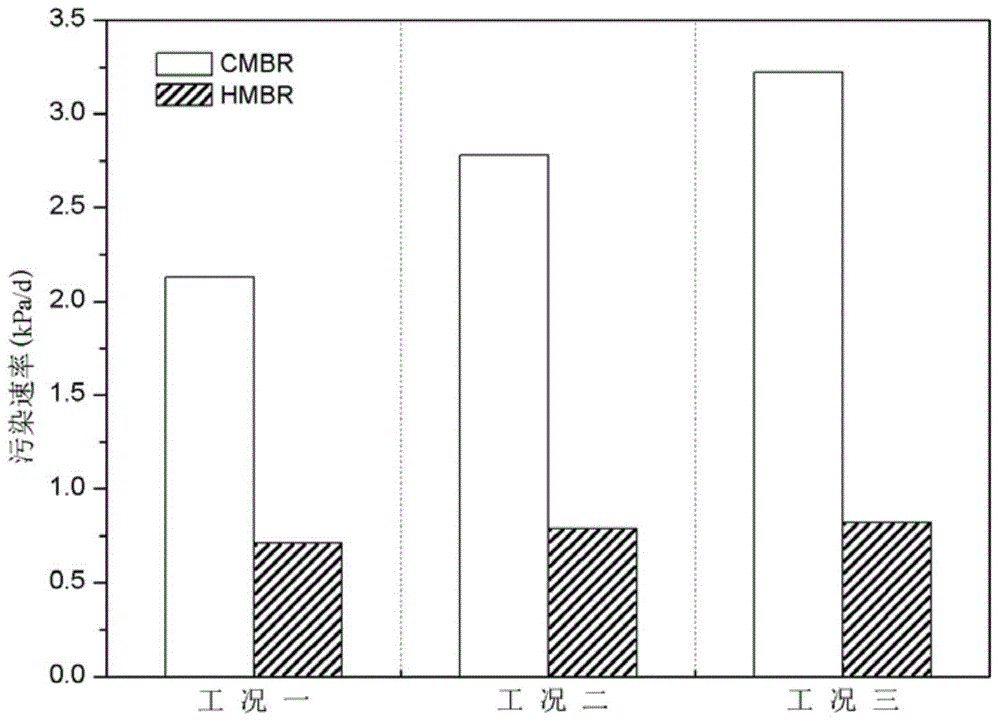

[0029] The structure of the reactor (CMBR) used in the control group is exactly the same as that of the reactor (HMBR) added with membrane fouling inhibitor. The effective volume of the reactor is 20L, and the fluctuation range of sludge concentration is 5-7mg / L. The hydraulic retention time (HRT) and sludge retention time (SRT) of the two sets of reactors were 6h and 30d, respectively. Domestic sewage influent chemical oxygen demand (COD cr ) is 300-500mg / L.

[0030] (1) First prepare 600mL of sodium alginate solution with a mass fraction of 2%, mix well; then prepare 250mL of allicin solution with a mass fraction of 30%, mix well for later use; finally prepare brominated furanone with a mass fraction of 5% Ethanol solution 150mL, mix well and set aside;

[0031] (2) Mix the prepared allicin solution evenly with the ethanol solution containing brominated furanone, then mix evenly with the sodium alginate solution, and leave to age for 2 hours;

[0032] (3) With a peristalt...

Embodiment 2

[0036] In this embodiment, the structure of the two sets of reactors used is the same as that of Embodiment 1. The fluctuating range of sludge concentration is 8-11g / L, and the operating parameters in the stable stage: HRT is 8h, SRT is 30d, domestic sewage influent COD cr It is 370mg / L~550mg / L.

[0037] (1) First prepare 600 mL of sodium alginate solution with a mass fraction of 3%, mix well; then prepare 250 mL of allicin solution with a mass fraction of 40%, mix well for later use; finally prepare brominated furanone with a mass fraction of 7% Ethanol solution 150mL, mix well and set aside;

[0038] (2) Mix the prepared allicin solution with the ethanol solution of furanone bromide evenly, then mix with the sodium alginate solution evenly, and let stand and age for 3h;

[0039] (3) With a peristaltic pump, the mixed solution of the three solutions after the aging is sucked into the calcium chloride solution with a mass fraction of 2% through a nozzle with an aperture of 2...

Embodiment 3

[0043] In this embodiment, the structure of the two sets of reactors used and the water quality of the domestic sewage are the same as those in Embodiment 2. The fluctuating range of sludge concentration is 10-15g / L, and the operating parameters are: HRT is 8h, SRT is 20d.

[0044] (1) First prepare 600mL of sodium alginate solution with a mass fraction of 4%, mix uniformly; then prepare 250mL of allicin solution with a mass fraction of 45%, mix well for later use; finally prepare brominated furanone with a mass fraction of 8% Ethanol solution 150mL, mix well and set aside;

[0045] (2) Mix the prepared allicin solution evenly with the ethanol solution containing brominated furanone, then mix evenly with the sodium alginate solution, and leave to age for 4 hours;

[0046] (3) With a peristaltic pump, the mixed solution of the three solutions after the aging is sucked into the calcium chloride solution with a mass fraction of 2% through a nozzle with an aperture of 2 mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com