Preparation method of magnetic Fe2O3/Fe3O4 nano-heteroplasmon particles

A heterogeneous, fe2o3 technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult control of preparation technology, limited particle application research, and difficult process control, etc. Achieve the effect of few types of raw materials, low equipment requirements, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 8.08 g of ferric nitrate to 20 mL of absolute ethanol, stir and dissolve for 2 h, put the sol solution in a crucible, ignite and burn it, and put it in a programmable temperature-controlled furnace at 3 °C / min Calcined at 400°C for 2 h, taken out after natural cooling, and ground to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Nano-heterogeneous particles.

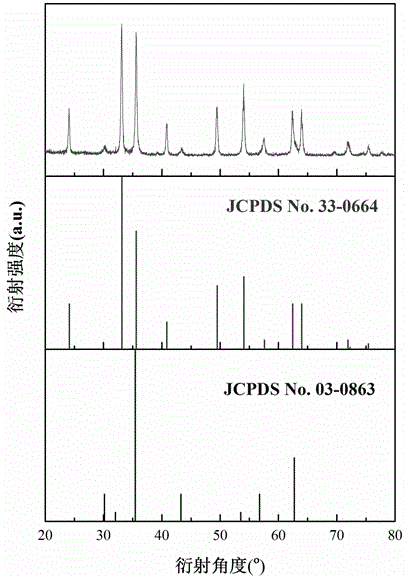

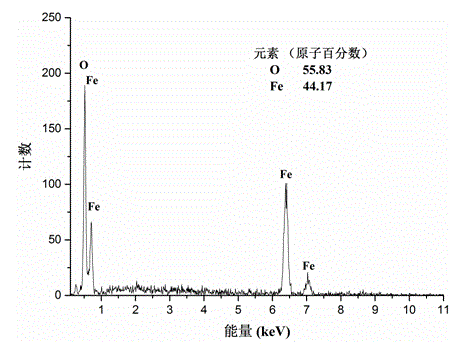

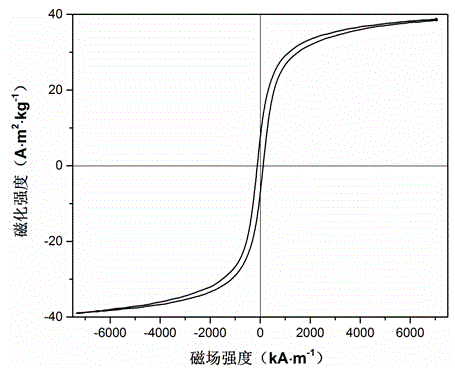

[0021] figure 1 For the magnetic Fe prepared under the conditions described in this example 2 o 3 / Fe 3 o 4 X-ray Diffraction Spectrum of Nanoheterogeneous Particles and Fe 2 o 3Standard PDF Card (JCPDS No. 33-0664) and Fe 3 o 4 Standard PDF card (JCPDS No. 03-0863) comparison chart; it can be seen from the figure that most of the diffraction peak positions of the product and Fe 2 o 3 Corresponding to the diffraction peak position of the standard PDF card, at 30 o and 43 o Fe appears on the diffraction angle 3 o 4 characteristic diffraction peaks, indicating that the Fe 3 o 4 composition; at the same t...

Embodiment 2

[0026] Add 8.64 g of ferric nitrate to 15 mL of absolute ethanol, stir and dissolve for 2 h, put the sol solution in a crucible, ignite and burn it, and put it in a programmable temperature-controlled furnace until the flame is exhausted. Calcined at 400°C for 0.1 h, taken out after natural cooling, and ground to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Nano-heterogeneous particles.

Embodiment 3

[0028] Add 5.00 g of iron acetate to 50 mL of absolute ethanol, stir and dissolve for 4 h, put the sol solution in a crucible, ignite it, and wait until the fire is exhausted, put it in a programmable temperature-controlled furnace at 7 °C / min Calcined at 150°C for 12 h, taken out after natural cooling, and ground to obtain magnetic Fe 2 o 3 / Fe 3 o 4 Nano-heterogeneous particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com