Graphene oxide and graphene oxide quantum dot solvothermal controllable preparation method and use thereof

A technology of graphene quantum dots and graphene, which is applied in the field of nanomaterial preparation, can solve the problems of difficult control of shape and size, low production efficiency of graphene quantum dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

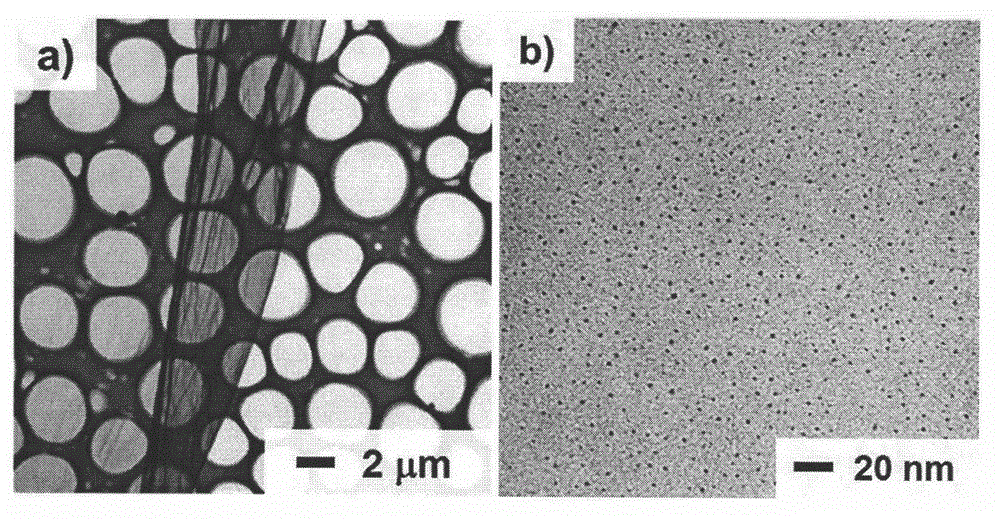

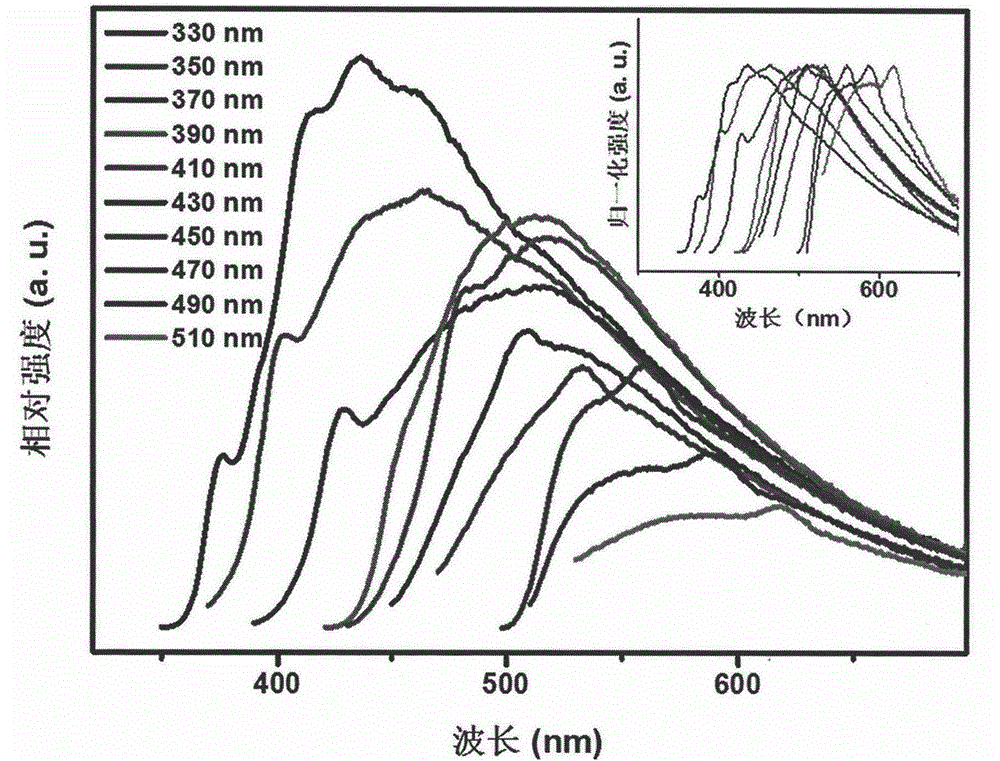

Image

Examples

Embodiment 1

[0018] Put graphite powder and potassium permanganate with a mass ratio of 1:3 into a beaker, add sulfuric acid and nitric acid with a volume ratio of 3:1, and stir for 30 minutes; transfer all the above reactants to a 25mL polytetrafluoroethylene reactor reaction in an oven at 130°C for 1.5 hours; after the reaction is complete, disperse it in 50mL deionized water for use; take a certain amount and add it to a dialysis bag with a molecular weight cut-off of 3500Da, and dialyze for 3-7 days; put the dialysis bag The solution in is freeze-dried to obtain graphene oxide powder.

Embodiment 2

[0020] Put graphite powder and potassium permanganate with a mass ratio of 1:3 into a beaker, add sulfuric acid and nitric acid with a volume ratio of 3:1, and stir for 30 minutes; transfer all the above reactants to a 25mL polytetrafluoroethylene reactor , react in an oven at 160°C for 1.5 hours; after the reaction is complete, disperse it in 50mL of deionized water for use; take a certain amount and add it to a dialysis bag with a molecular weight cut-off of 1000Da, and dialyze for 3-7 days; put the dialysis bag The solution in is freeze-dried to obtain graphene oxide quantum dot powder.

Embodiment 3

[0022] Put graphite powder and potassium permanganate with a mass ratio of 4:3 into a beaker, add sulfuric acid and nitric acid with a volume ratio of 3:1, and stir for 30 minutes; transfer all the above reactants to a 25mL polytetrafluoroethylene reactor reaction in an oven at 160°C for 1.5 hours; after the reaction is complete, disperse it in 50 mL of deionized water for use; add the dispersed product to a dialysis bag with a molecular weight cut-off of 1000 Da, and dialyze for 3-7 days; The solution in the dialysis bag is freeze-dried to obtain graphene oxide quantum dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com