Tenderized and air-dried beef preparation method

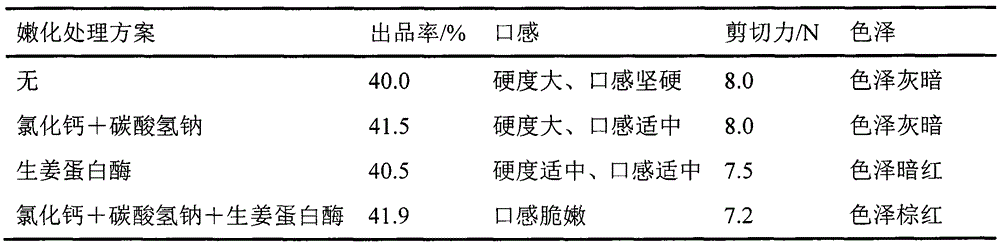

An air-dried beef and tenderization technology is applied in the preparation field of tenderized air-dried beef, which can solve the problems of easy product bitterness, dark color and complicated operation, and achieve the effects of easy control of reaction conditions, reduction of water loss and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of tenderized air-dried beef, which comprises the following steps:

[0020] (1) Remove fascia, tendon, cartilage, lymph, congestion, fat and dirt from large pieces of beef for trimming, and then use a saline injection machine to inject tenderizer into the trimmed beef pieces for tenderization; tenderization The weight ratio of each component of the agent is: 180 parts of calcium chloride, 30 parts of sodium bicarbonate, 1.0 part of ginger protease, 15000 parts of purified water, and the activity of ginger protease is 18000U / g; 2.0%, under the temperature condition of 22 ℃, static pickling treatment for 2.5h;

[0021] (2) The tenderized beef block is cut into beef strips along the muscle fiber direction, and then the beef strips are placed in a vacuum tumbler and added with condiments for rolling and marinating; the weight ratio of beef strips and various condiments is : 100 parts of beef strips, 2 parts of salt, 0.5 parts of sugar, 1 part of baking...

Embodiment 2

[0026] A preparation method of tenderized air-dried beef, which comprises the following steps:

[0027] (1) Remove fascia, tendon, cartilage, lymph, congestion, fat and dirt from large pieces of beef for trimming, and then use a saline injection machine to inject tenderizer into the trimmed beef pieces for tenderization; tenderization The weight ratio of each component of the agent is: 130 parts of calcium chloride, 35 parts of sodium bicarbonate, 0.8 part of ginger protease, 14000 parts of purified water, and the activity of ginger protease is 20000U / g; 1.4%, under the temperature condition of 20 ℃, static pickling treatment for 3 hours;

[0028] (2) The tenderized beef block is cut into beef strips along the muscle fiber direction, and then the beef strips are placed in a vacuum tumbler and added with condiments for rolling and marinating; the weight ratio of beef strips and various condiments is : 100 parts of beef strips, 1.5 parts of salt, 1 part of baking soda, 0.2 part...

Embodiment 3

[0033] A preparation method of tenderized air-dried beef, which comprises the following steps:

[0034] (1) Remove fascia, tendon, cartilage, lymph, congestion, fat and dirt from large pieces of beef for trimming, and then use a saline injection machine to inject tenderizer into the trimmed beef pieces for tenderization; tenderization The weight ratio of each component of agent is: 220 parts of calcium chloride, 25 parts of sodium bicarbonate, 1.4 parts of ginger protease, 18000 parts of purified water, the activity of ginger protease is 22000U / g; 1.0%, under the temperature condition of 25 ℃, static pickling treatment for 2 hours;

[0035] (2) The tenderized beef block is cut into beef strips along the muscle fiber direction, and then the beef strips are placed in a vacuum tumbler and added seasonings for rolling and marinating; the weight ratio of beef strips and various seasonings is : 100 parts of beef strips, 2.5 parts of salt, 1 part of sugar, 0.4 parts of pepper powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com