Sweet potato protein paste and preparation method thereof

A protein paste and sweet potato technology, which is applied in the field of miscellaneous grain processing, can solve the problems that sweet potato protein cannot be eaten directly, restricts the use of sweet potato protein, and has high impurity content, and achieves the effects of environmental protection, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A sweet potato protein paste, comprising the following raw materials in parts by mass: 40 parts of sweet potato leaves, 70 parts of sweet potatoes, 35 parts of glutinous rice flour, 4 parts of astragalus, 4 parts of Codonopsis pilosula, 3 parts of gallinaceous gold, 3 parts of tangerine, and 5 parts of black beans , 5 parts of peanuts, 4 parts of yam, 3 parts of wolfberry, 3 parts of red dates, 3 parts of carrots, and 4 parts of sugar.

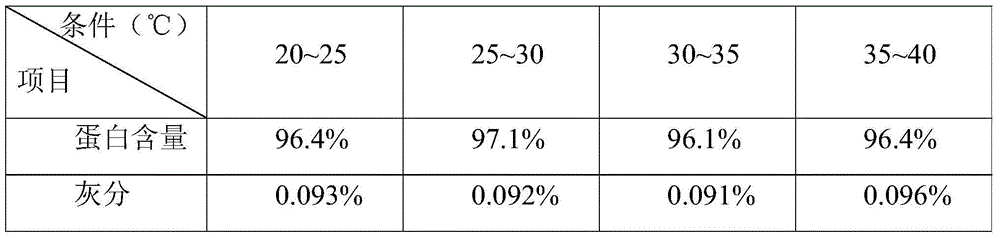

[0020] Wash and crush the sweet potatoes, pass through a 30-mesh sieve, add the sieved sweet potatoes to a constant temperature stirring tank, add pure water with a volume 4 times the volume of the crushed sweet potatoes to the stirring tank, stir and soak for 8 hours at a temperature of 20°C , take the supernatant ①, centrifuge the supernatant ① at 1000r / min for 15min to obtain the supernatant ②, filter the supernatant ② through a food-grade activated carbon layer or suction filter, take the filtrate, and dilute the mass concentration t...

Embodiment 2

[0022]A sweet potato protein paste, comprising the following raw materials in parts by mass: 60 parts of sweet potato leaves, 85 parts of sweet potatoes, 50 parts of glutinous rice flour, 12 parts of astragalus, 10 parts of Codonopsis pilosula, 9 parts of gallinaceous gold, 9 parts of tangerine, and 10 parts of black beans , 11 parts of peanuts, 9 parts of yam, 9 parts of wolfberry, 8 parts of red dates, 8 parts of carrots, and 11 parts of white sugar.

[0023] Wash and crush the sweet potatoes, pass through a 30-mesh sieve, put the sieved sweet potatoes into a constant temperature stirring tank, add pure water with a volume 4 times the volume of the crushed sweet potatoes into the stirring tank, stir and soak for 16 hours at a temperature of 25°C , take the supernatant ①, centrifuge the supernatant ① at 1000r / min for 15min to obtain the supernatant ②, filter the supernatant ② through a food-grade activated carbon layer or suction filter, take the filtrate, and dilute the mass ...

Embodiment 3

[0025] A sweet potato protein paste, comprising the following raw materials in parts by mass: 45 parts of sweet potato leaves, 75 parts of sweet potato, 40 parts of glutinous rice flour, 6 parts of astragalus, 6 parts of Codonopsis pilosula, 5 parts of gallinaceous gold, 4 parts of tangerine, and 6 parts of black beans , 7 parts of peanuts, 6 parts of yam, 5 parts of wolfberry, 5 parts of red dates, 5 parts of carrots, and 7 parts of sugar.

[0026] Wash and crush the sweet potatoes, pass through a 30-mesh sieve, put the sieved sweet potatoes into a constant temperature stirring tank, add pure water with a volume 4 times the volume of the crushed sweet potatoes into the stirring tank, stir and soak for 10 hours at a temperature of 30°C , take the supernatant ①, centrifuge the supernatant ① at 1000r / min for 15min to obtain the supernatant ②, filter the supernatant ② through a food-grade activated carbon layer or suction filter, take the filtrate, and dilute the mass concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com