Cathode for lead-carbon batteries, production method of cathode and battery made with cathode

A lead-carbon battery and negative electrode technology, applied in lead-acid battery electrodes, battery electrodes, lead-acid batteries, etc., can solve the problems of difficult to convert Pb, reduce surface area, etc., to improve conversion activity, prolong service life, and alleviate the irreversibility of negative electrodes. The effect of sulfation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

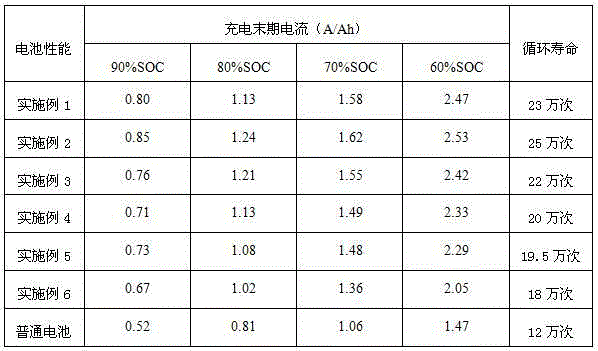

Examples

Embodiment 1

[0048] A lead-carbon battery negative electrode comprises the following components in parts by weight:

[0049] 8.5 parts of sulfuric acid,

[0050] 0.5 parts of barium sulfate,

[0051] Norwegian lignin 0.1 part,

[0052] Nylon 0.05 parts,

[0053] 0.2 part of graphene nanobelt,

[0054] 0.01 part of silane coupling agent,

[0055] Lignosulfonate 0.05 part,

[0056] Nano titanium dioxide 0.02 parts,

[0057] Nano silicon dioxide 0.04 part,

[0058] 10 parts pure water,

[0059] 70 parts of lead powder;

[0060]Wherein, the density of the sulfuric acid is 1.38g / mL; the specific surface area of the graphene nanobelt is 180 ~ 300m 2 / g, the average pore diameter is less than 50nm;

[0061] According to the composition formula of above-mentioned lead-carbon battery negative pole, make following preparation:

[0062] (1) Premix barium sulfate, organic expansion agent, graphene nanobelts, short fibers, nano-titanium dioxide and nano-silicon dioxide for 5 minutes;

[0...

Embodiment 2

[0069] A lead-carbon battery negative electrode comprises the following components in parts by weight:

[0070] 9.2 parts of sulfuric acid,

[0071] 1.0 parts of barium sulfate,

[0072] 0.25 parts of humic acid,

[0073] 0.12 part of acrylic fiber,

[0074] 0.4 parts of graphene nanoribbons,

[0075] 0.15 parts of silane coupling agent,

[0076] 0.06 parts of cellulose derivatives,

[0077] Nano titanium dioxide 0.03 part,

[0078] Nano silicon dioxide 0.06 part,

[0079] 13 parts of pure water,

[0080] 76 parts of lead powder;

[0081] Wherein, the density of the sulfuric acid is 1.38g / mL; the specific surface area of the graphene nanobelt is 300 ~ 430m 2 / g, the average pore size is 20nm~35nm;

[0082] According to the composition formula of above-mentioned lead-carbon battery negative pole, make following preparation:

[0083] (1) Premix barium sulfate, organic expansion agent, graphene nanobelts, short fibers, nano-titanium dioxide and nano-silicon dioxide f...

Embodiment 3

[0090] A lead-carbon battery negative electrode comprises the following components in parts by weight:

[0091] 10 parts of sulfuric acid,

[0092] 1.5 parts of barium sulfate,

[0093] 0.4 parts of humic acid,

[0094] 0.2 parts of polyester,

[0095] 5 parts of graphene nanoribbons,

[0096] 0.5 part of silane coupling agent,

[0097] 0.08 part of polycarboxylate,

[0098] Nano titanium dioxide 0.04 parts,

[0099] Nano silicon dioxide 0.08 parts,

[0100] 15 parts of pure water,

[0101] 80 parts of lead powder;

[0102] Wherein, the density of the sulfuric acid is 1.38g / mL; the specific surface area of the graphene nanobelt is 430 ~ 500m 2 / g, the average pore diameter is less than 50nm;

[0103] According to the composition formula of above-mentioned lead-carbon battery negative pole, make following preparation:

[0104] (1) Premix barium sulfate, organic expansion agent, graphene nanobelts, short fibers, nano-titanium dioxide and nano-silicon dioxide for 5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com