Preparation method for uniform organic-inorganic perovskite film solar cell

A technology of solar cells and inorganic calcium, applied in the field of solar cells, can solve the problems of the influence of the photoelectric properties of thin films, residues, etc., and achieve the effects of improving repeatability, low environmental requirements, and improving coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) First, 1.48 g of potassium hydroxide (KOH) was dissolved in 65 mL of methanol to obtain solution X, and then 2.95 g of zinc acetate dihydrate was dissolved in 125 mL of methanol to obtain solution Y. Put the solution Y in a water bath at 60°C, and add all the solution X to the solution Y dropwise under constant stirring. The temperature of the water bath was raised to 65°C, and stirred at this temperature for 2.5h to obtain a sol. After the sol was cooled to room temperature and naturally precipitated, the precipitate was washed twice with methanol, and then an appropriate amount of the precipitate was dispersed into 2mL of methanol, 2mL of chloroform and 16mL of n-butanol to obtain zinc oxide with a concentration of 6mg / mL The sol is ready for use.

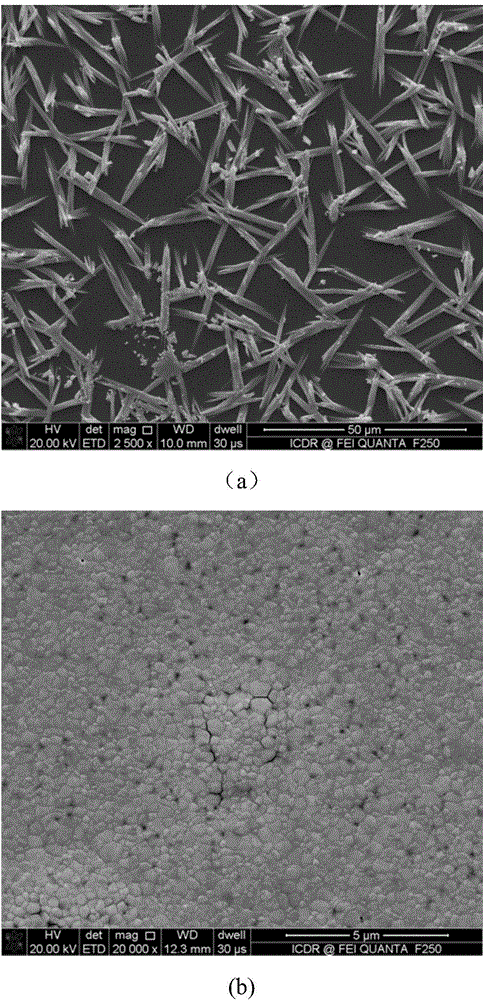

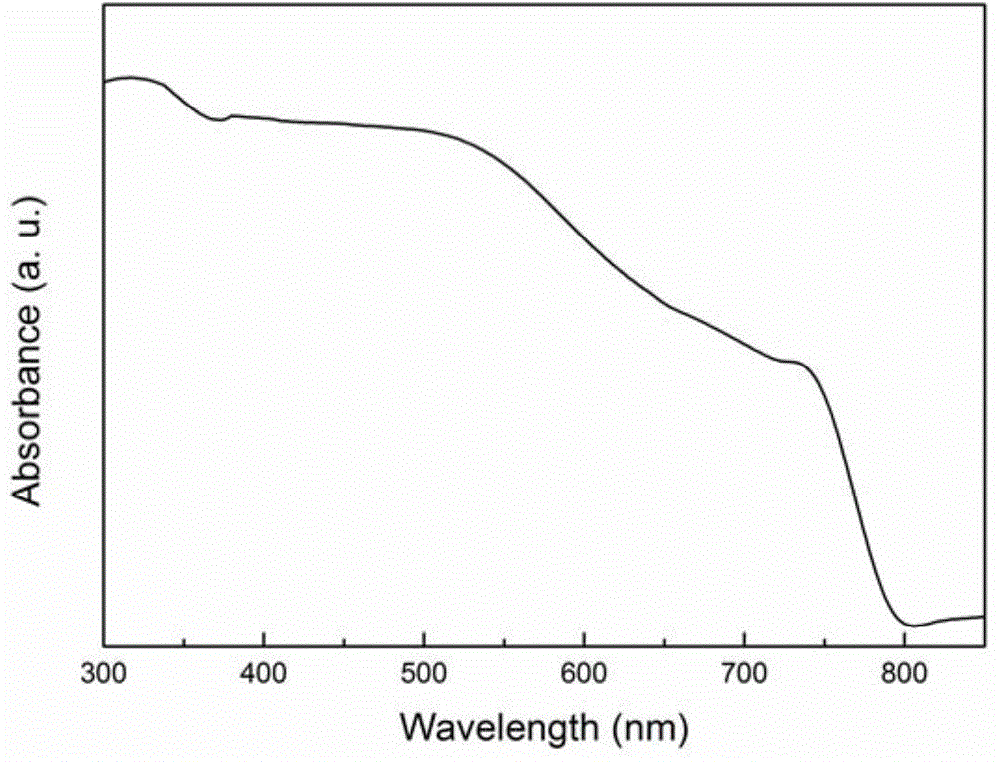

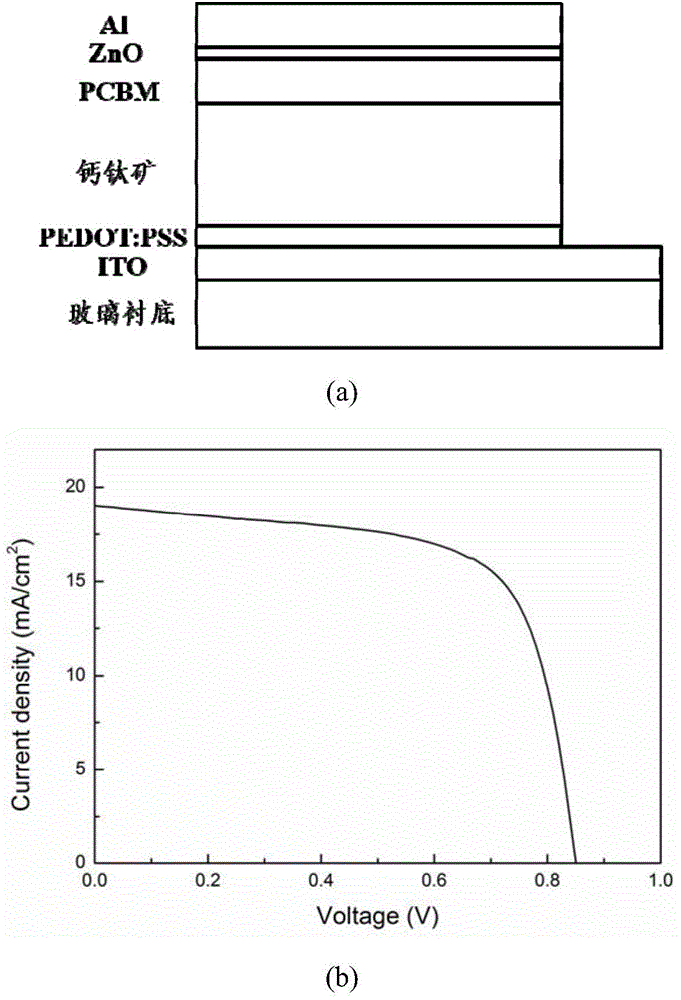

[0026] 2) Add 2.3g of lead iodide and 0.8g of potassium iodide ammonium to a 10ml brown screw bottle, and then add 5ml of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) to it, wherein The volume ratio of DM...

Embodiment 2

[0030] 1) First, dissolve 1.45 potassium hydroxide (KOH) in 65 mL of methanol to obtain solution X, then dissolve 2.9 g of zinc acetate dihydrate in 130 mL of methanol to obtain solution Y. Put the solution Y in a water bath at 60°C, and add all the solution X to the solution Y dropwise under constant stirring. The temperature of the water bath was raised to 65°C, and stirred at this temperature for 2.5h to obtain a sol. After the sol was cooled to room temperature and naturally precipitated, the precipitate was washed twice with methanol, and then an appropriate amount of the precipitate was dispersed into 2mL of methanol, 2mL of chloroform and 16mL of n-butanol to obtain zinc oxide with a concentration of 6mg / mL The sol is ready for use.

[0031] 2) Add 2.3g of lead iodide and 0.8g of potassium iodide ammonium to a 10ml brown screw bottle, and then add 5ml of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) to it, wherein The volume ratio of DMF and DMSO is 5:5. ...

Embodiment 3

[0035] 1) First, 1.5 g of potassium hydroxide (KOH) was dissolved in 70 mL of methanol to obtain solution X, and then 2.95 g of zinc acetate dihydrate was dissolved in 120 mL of methanol to obtain solution Y. Put the solution Y in a water bath at 60°C, and add all the solution X to the solution Y dropwise under constant stirring. The temperature of the water bath was raised to 65°C, and stirred at this temperature for 2.5h to obtain a sol. After the sol was cooled to room temperature and naturally precipitated, the precipitate was washed twice with methanol, and then an appropriate amount of the precipitate was dispersed in 2 mL of methanol, 2 mL of chloroform and 16 mL of n-butanol to obtain zinc oxide with a concentration of 5 mg / mL The sol is ready for use.

[0036] 2) Add 2.3g of lead iodide and 0.8g of potassium iodide ammonium to a 10ml brown screw bottle, and then add 5ml of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) to it, wherein The volume ratio of D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com