Novel high density integrated electric inductance manufacturing method

A manufacturing method and high-density technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of poor electromagnetic performance of inductors, poor heat dissipation, large size, etc. , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

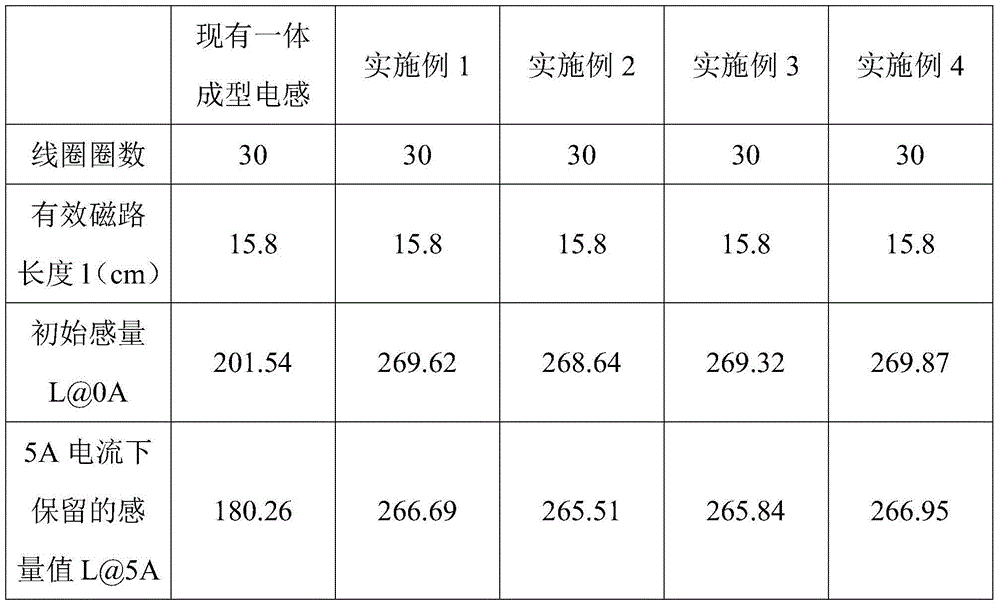

Examples

Embodiment 1

[0044] A method for manufacturing a novel high-density integrated molded inductor, comprising the following steps:

[0045] (1) Through the automatic winding machine, the enameled wire coil is wound in a spiral shape;

[0046] (2) Mechanically compress the first ferromagnetic powder to a density of 6.5g / cm 3 The magnetic core, the first ferromagnetic powder is iron silicon powder;

[0047] (3) packing the magnetic core into the hollow cavity of the enameled wire coil;

[0048] (4) packing the enameled wire coil with the magnetic core into the injection mold;

[0049](5) Mix and stir the modified epoxy silicone resin, mercaptopropylmethyldimethoxysilane, and m-xylylenediamine in a weight ratio of 7:1:2 to obtain a high-temperature resin glue;

[0050] (6) Mix and stir the second ferromagnetic powder and the high-temperature resin glue according to the weight ratio of 94:6 to obtain a magnetic composite material. The second ferromagnetic powder is composed of -100 mesh to 200...

Embodiment 2

[0055] A method for manufacturing a novel high-density integrated molded inductor, comprising the following steps:

[0056] (1) Through the automatic winding machine, the enameled wire coil is wound in a spiral shape;

[0057] (2) The first ferromagnetic powder is mechanically pressed to a density of 6.2g / cm 3 The magnetic core, the first ferromagnetic powder is iron silicon powder;

[0058] (3) packing the magnetic core into the hollow cavity of the enameled wire coil;

[0059] (4) packing the enameled wire coil with the magnetic core into the injection mold;

[0060] (5) Mix and stir the modified epoxy silicone resin, mercaptopropylmethyldimethoxysilane, and m-xylylenediamine in a weight ratio of 75:7:18 to obtain a high-temperature resin glue;

[0061] (6) Mix and stir the second ferromagnetic powder and the high-temperature resin glue in a weight ratio of 9:1 to obtain a magnetic composite material. The second ferromagnetic powder is composed of -100 mesh to 200 mesh, -...

Embodiment 3

[0066] A method for manufacturing a novel high-density integrated molded inductor, comprising the following steps:

[0067] (1) Through the automatic winding machine, the enameled wire coil is wound in a spiral shape;

[0068] (2) Mechanically compress the first ferromagnetic powder to a density of 6.9g / cm 3 The magnetic core, the first ferromagnetic powder is iron silicon powder;

[0069] (3) packing the magnetic core into the hollow cavity of the enameled wire coil;

[0070] (4) packing the enameled wire coil with the magnetic core into the injection mold;

[0071] (5) Epoxy silicone resin, mercaptopropylmethyldimethoxysilane, and m-xylylenediamine are mixed and stirred evenly in a weight ratio of 80:5:15 to obtain a high-temperature resin glue;

[0072] (6) Mix and stir the second ferromagnetic powder and the high-temperature resin glue according to the weight ratio of 88:12 to obtain a magnetic composite material. The second ferromagnetic powder is composed of -100 mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com