Copper-based hyperelastic shape memory alloy wire and preparation method thereof

A technology of memory alloy wire and superelasticity, which is applied in the field of copper-based superelastic shape memory alloy, can solve the problems of difficult preparation of single crystal wire, difficulty in cold processing of polycrystalline alloy, and impossibility of practical application, so as to overcome polycrystalline brittleness Problems, low cost, excellent effect of hyperelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

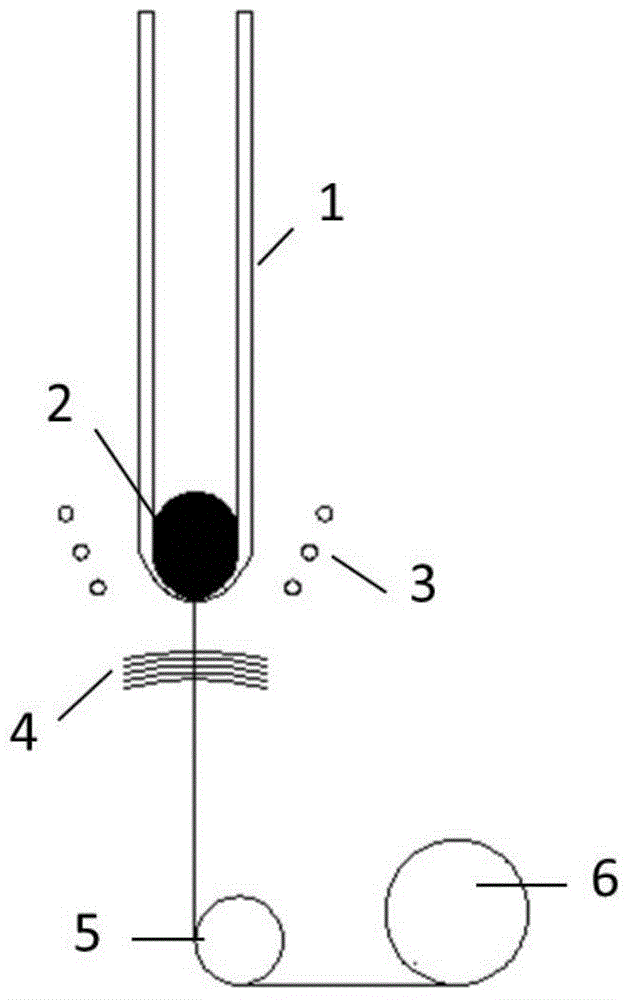

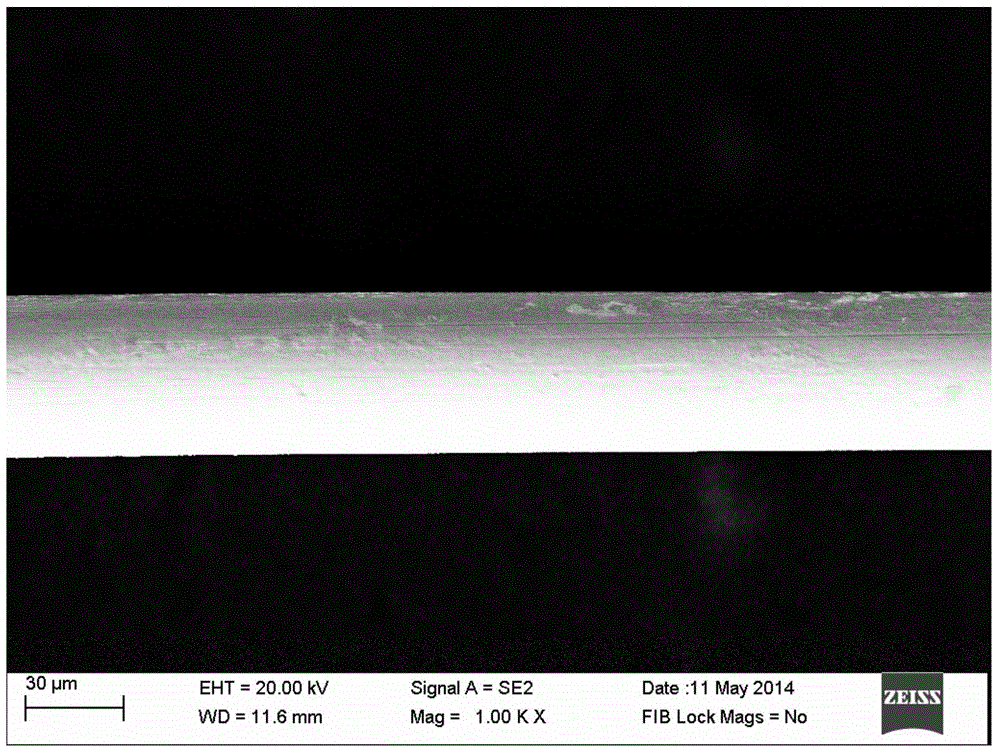

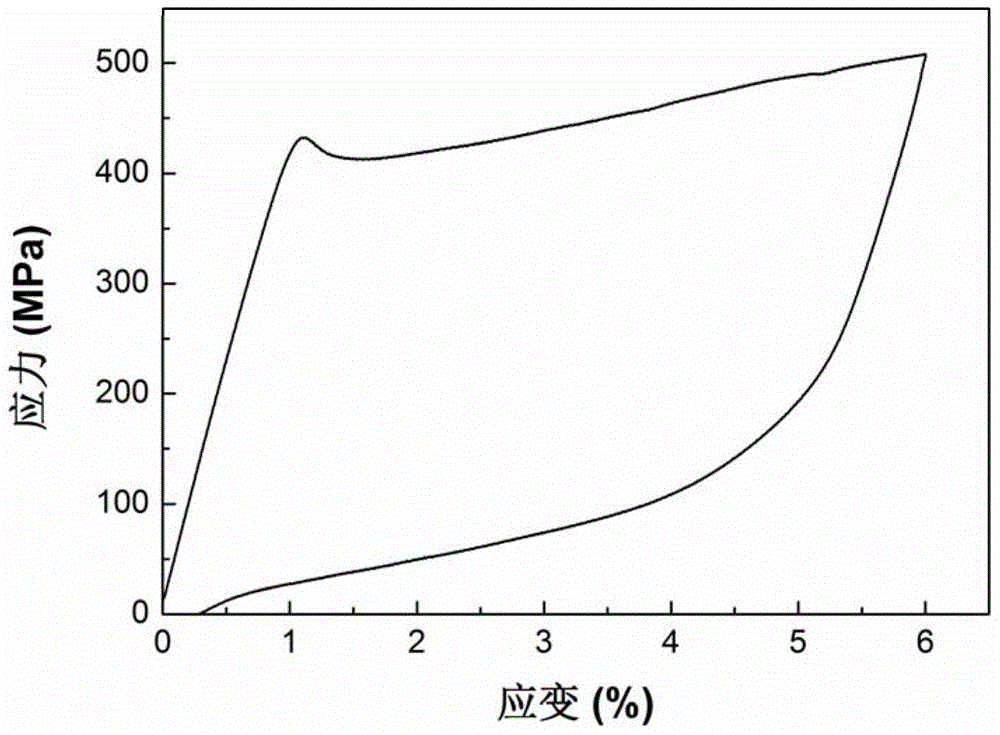

[0029] The molecular formula of the copper-based superelastic memory alloy wire of this example is Cu 84 sn 16 , the preparation steps are as figure 1 Shown: Prepare 20g of raw materials Cu and Sn with a purity greater than 99% according to the composition of this example, and then smelt them in a high-frequency induction melting furnace under the protection of argon. Break the smelted alloy ingot into small pieces of 1~3g, put a small piece of alloy material weighing 2g into the bottom of the high borosilicate glass tube, the outer diameter of the glass tube is 10mm, and the wall thickness is 1mm. Fix the glass tube filled with the alloy material, turn on the mechanical pump to evacuate to 2.5Pa, and then fill it with argon to 0.1MPa. Start the high-frequency induction device and gradually increase the heating current to 350A. At this time, the alloy ingot melts, the bottom of the glass tube softens, and the molten alloy liquid and the glass at the bottom form a micro-melti...

Embodiment 2

[0031] The molecular formula of the copper-based superelastic memory alloy wire of this example is Cu 86 sn 14 , the preparation steps are as follows: prepare 20g of raw materials Cu and Sn with a purity greater than 99% according to the composition of this example, and then melt them in a high-frequency induction melting furnace under the protection of argon. Break the smelted alloy ingot into small pieces of 1~3g, and put a small piece of alloy material weighing 2g into the bottom of the glass tube. Fix the glass tube filled with the alloy material, turn on the mechanical pump to evacuate to 2.5Pa, and then fill it with argon to 0.1MPa. Start the high-frequency induction device and gradually increase the heating current to 400A. At this time, the alloy ingot melts, the bottom of the glass tube softens, and the molten alloy liquid and the glass at the bottom form a micro-melting pool. The temperature of the micro-melting pool is controlled at about 1100°C, and then the glas...

Embodiment 3

[0033] The molecular formula of the copper-based superelastic memory alloy wire of this example is Cu 83 sn 17 , the preparation steps are as follows: prepare 20g of raw materials Cu and Sn with a purity greater than 99% according to the composition of this example, and then melt them in a high-frequency induction melting furnace under the protection of argon. Break the smelted alloy ingot into small pieces of 1~3g, and put a small piece of alloy material weighing 2g into the bottom of the glass tube. Fix the glass tube filled with the alloy material, turn on the mechanical pump to evacuate to 2.5Pa, and then fill it with argon to 0.1MPa. Start the high-frequency induction device and gradually increase the heating current to 330A. At this time, the alloy ingot melts, the bottom of the glass tube softens, and the molten alloy liquid and the glass at the bottom form a micro-melting pool. The temperature of the micro-melting pool is controlled at about 950°C, and then the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com