Production process of waterborne polyurethane coating material having high tension force coating film

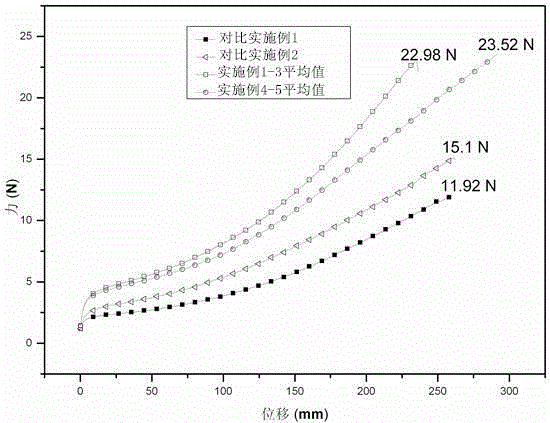

A water-based polyurethane and production process technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of brightness, fastness, dry and wet rubbing resistance, etc., and achieve plump hand feeling, increased length, and increased strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

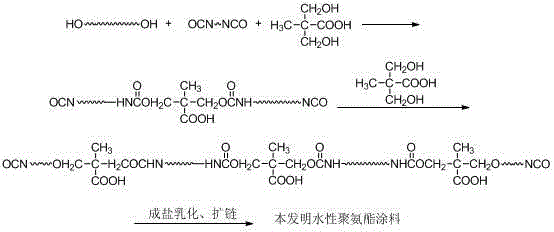

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Add 50 parts of polyether polyol PTMG-2000, 20 parts of polyadipate-1,4-butylene glycol ester diol, 1.6 parts of dimethylol butyric acid (DMBA) into the reaction bottle, after heating to 78 °C , then add 31 parts of toluene diisocyanate (TDI), lower the temperature to 70°C and continue the reaction for 25 minutes; add 1,4-butanediol (BDO) (the type of small molecule chain extender is variable, see Table I ) After 4.3 parts, heat up to 80 °C and keep it warm for 25 minutes; then add 4.0 parts of dimethylolbutyric acid (DMBA) again, and raise the reaction temperature to 85 °C for 25 minutes; take samples to measure the NCO % value, if it does not reach the theoretical value , then raise the temperature to 90 ℃; after reaching the theoretical NCO % value, add ethylene glycol dimethyl ether-acetone mixed solvent (solvent A system) to reduce the viscosity of the reaction system, and lower the temperature to 30-40 ℃, add neutralizing agent triethylamine 3.2 part...

Embodiment 2

[0032] Example 2:Add 50 parts of polyether polyol PTMG-2000, 20 parts of polyethylene adipate diol, and 3.0 parts of 1,4-butanediol-2-sodium sulfonate into the reaction bottle, and heat it to 78°C. Then add 30 parts of hexamethylene diisocyanate (HDI), lower the temperature to 70°C and continue the reaction for 30 minutes; add 4.3 parts of 1,4-butanediol (BDO) (the type of small molecule chain extender is variable, similar to Table 1) After that, the temperature was raised to 80 °C and kept for 30 min; then 4.2 parts of 1,4-butanediol-2-sodium sulfonate was added again, and the reaction temperature was increased to 85 °C for 30 min; samples were taken to determine the NCO % value, if not When the theoretical value is reached, raise the temperature to 90 °C; after reaching the theoretical NCO % value, add ethylene glycol dimethyl ether-acetone mixed solvent (solvent A system) to reduce the viscosity of the reaction system, and cool down to 30-40 °C, then add neutralizer 3.2 p...

Embodiment 3

[0033] Example 3: Add 50 parts of polyether polyol PTMG-2000, 20 parts of polycarbonate diol 980R, 2.9 parts of dimethylol propionic acid (DMPA) into the reaction bottle, heat to 78°C, and then add xylylene 33 parts of diisocyanate (XDI), lower the temperature to 70°C and continue the reaction for 35 minutes; add 3 parts of 1,4-butanediol (BDO) (the type of small molecule chain extender is variable, similar to Table 1), and then heat up to 80°C , and keep it warm for 35 minutes; then add 2.1 parts of dimethylolpropionic acid (DMPA) again, and increase the reaction temperature to 85 ℃ for 35 minutes; take a sample to measure the NCO % value, if it does not reach the theoretical value, then raise the temperature to 90 ℃; reach the theoretical value After the NCO% value is reached, add ethylene glycol dimethyl ether-acetone mixed solvent (solvent A system) to reduce the viscosity of the reaction system, and lower the temperature to 30-40 °C, add 3.2 parts of neutralizing agent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com