Complex extraction method for separation and purification of pyrroloquinoline quinine in fermentation broth

A technology for separation and purification of pyrroloquinoline quinone, which is applied in the field of separation and purification of water-soluble vitamins, can solve the problems of not finding and preparing PQQ, etc., and achieve the effect of facilitating large-scale industrial production, fast process and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

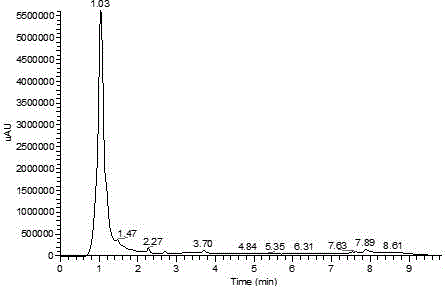

Image

Examples

Embodiment 1

[0028] The complex extraction method separates and purifies the pyrroloquinoline quinone in the fermented liquid, and its steps are as follows:

[0029] (1) Fermenting Gluconobacter oxydans DSM 2003 to obtain a fermentation broth;

[0030] (2) After the fermentation broth is centrifuged at high speed, the supernatant is subjected to complex extraction in a two-solute extraction system, in which trioctylamine is used as a complexing agent and n-hexane is used as a diluent to obtain a supernatant rich in pyrroloquinoline quinone. The volume ratio of trioctylamine and n-hexane in the dual-solute extraction system is 1:1, the volume ratio of the extraction system to the fermentation broth is 1:1, and the extraction times are 3 times;

[0031] (3) Back-extracting the upper layer rich in pyrroloquinoline quinone with ammonia water, concentrating the ammonia water layer under reduced pressure, and freeze-drying to obtain the crude product of pyrroloquinoline quinone, the concentratio...

Embodiment 2

[0034] The complex extraction method separates and purifies the pyrroloquinoline quinone in the fermented liquid, and its steps are as follows:

[0035] (1) Fermenting Gluconobacter oxydans DSM 2003 to obtain a fermentation broth;

[0036] (2) After the fermentation broth is centrifuged at high speed, the supernatant is subjected to complex extraction in a two-solute extraction system, in which trioctylamine is used as a complexing agent and n-hexane is used as a diluent to obtain a supernatant rich in pyrroloquinoline quinone. The volume ratio of trioctylamine and n-hexane in the dual-solute extraction system is 3:1, the volume ratio of the extraction system to the fermentation broth is 3:1, and the number of extractions is 5 times;

[0037] (3) Back-extracting the upper layer rich in pyrroloquinoline quinone with ammonia water, concentrating the ammonia water layer under reduced pressure, and freeze-drying to obtain the crude product of pyrroloquinoline quinone, the concentr...

Embodiment 3

[0040]The complex extraction method separates and purifies the pyrroloquinoline quinone in the fermented liquid, and its steps are as follows:

[0041] (1) Fermenting Gluconobacter oxydans DSM 2003 to obtain a fermentation broth;

[0042] (2) After the fermentation broth is centrifuged at high speed, the supernatant is subjected to complex extraction in a two-solute extraction system, in which trioctylamine is used as a complexing agent and n-hexane is used as a diluent to obtain a supernatant rich in pyrroloquinoline quinone. The volume ratio of trioctylamine and n-hexane in the dual-solute extraction system is 2:1, the volume ratio of the extraction system to the fermentation broth is 2:1, and the number of extractions is 4 times;

[0043] (3) Back-extracting the upper layer rich in pyrroloquinoline quinone with ammonia water, concentrating the ammonia water layer under reduced pressure, and freeze-drying to obtain the crude product of pyrroloquinoline quinone, the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com