Methoxyactic acid preparation method

A technology of methoxyacetic acid and oxygen, applied in the preparation of carboxylates, organic compounds, chemical instruments and methods, etc., can solve the problems of corrosion, high comprehensive production cost, cumbersome process flow, etc., and achieve mild reaction conditions, Easy operation and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

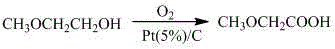

Method used

Image

Examples

Embodiment 1

[0023] Add 30 mL (28.8 g) of ethylene glycol monomethyl ether, 40 mL of deionized water and 0.25 g of Pt(5wt%) / C catalyst into the autoclave, adjust O 2 The pressure keeps the pressure of the reactor at 0.6 MPa and reacts at 70℃ for 7 hours. After the reactor is cooled to room temperature, the catalyst is filtered and washed to recover the catalyst. The filtrate is distilled under reduced pressure to collect the 92-94℃ / 10 mmHg fraction to obtain the methoxy group. Acetic acid is 30.35g, the yield is 91%, and the purity is 99%.

Embodiment 2

[0025] Add 30 mL (28.8 g) of ethylene glycol monomethyl ether, 30 mL of deionized water and 0.15 g of Pt(5wt%) / C catalyst into the autoclave, adjust O 2 The pressure keeps the pressure of the reactor at 0.5 MPa and reacts at 60℃ for 6 hours. After the reactor is cooled to room temperature, the catalyst is filtered and washed to recover the catalyst. The filtrate is distilled under reduced pressure to collect the 92-94℃ / 10 mmHg fraction to obtain the methoxy group. Acetic acid is 30.69 g, the yield is 90%, and the purity is 99%.

Embodiment 3

[0027] Put 30 mL (28.8 g) of ethylene glycol monomethyl ether, 45 mL of deionized water and 0.32 g of Pt(5wt%) / C catalyst in the autoclave, and adjust O 2 The pressure keeps the pressure of the reactor at 0.8 MPa, and reacts at 80℃ for 6 hours. After the reactor is cooled to room temperature, the catalyst is filtered and washed to recover the catalyst. The filtrate is distilled under reduced pressure to collect the 92-94℃ / 10 mmHg fraction to obtain the methoxy group. Acetic acid 31.37 g, yield 92%, purity 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com